microPEM® Product Family

- Wearables

- Laptops

- Tablets/Readers

- Cell/Smart Phones

- Gaming/Hand Held Devices

- Infotainment

- Automotive Electronics

- Thread code as small as M0.8

- Pin diameters as small as 0.7mm

- Standoff lengths as short as .028" / 0.7mm

- Clinches flush into sheets as thing as .012" / 0.3mm

- Attach sheets as thin as .008" / 0.2mm. Parts for smaller and/or thinner applications can be designed.

microPEM® Products

microPEM® FlexTack™ Fasteners

Designed to increase vertical installation in designs

- Alternative to using micro-screws, eliminating the need to tap or use threaded inserts.

- Installation time to simply press the part in (1.5 seconds) is less than the time to thread a screw in, equals less total installed cost.

- The Belleville-shaped head allows for stack-up tolerance relief in a design.

- Lowers overall total installed costs from the elimination of the following: patch to prevent loosening, threaded insert or tapped hole and driver bits, cost of rework due to cross-threading or driver bit “cam-out”

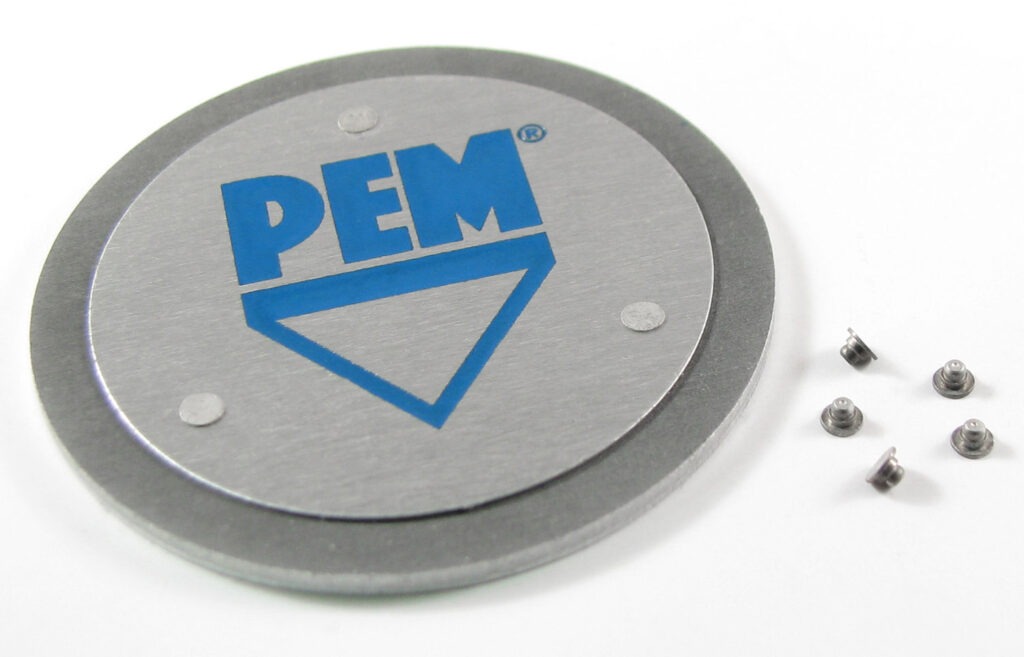

microPEM® ClampDisk® Fastener

- Clamp load generation.

- Simple installation.

- Removability.

- Works with multiple panels of any material.

- Limited installation stress to assemble.

microPEM® TackSert® Type TK™ Pins

- Secure panels to common magnesium die casting materials such as AZ91D.

- Appropriate for attaching panels to plastics such as ABS.

- Simple, press-in installation. Does not require heat or ultrasonics.

- Alternative to micro screws, eliminating many of the costs associated with threaded hardware.

- Top sheet can be any material.

- Low-profile head.

microPEM® Self-Clinching TackPin® Fasteners

Designed for Sheet-to-Sheet Attachment

- Replaces and reduces costs associated with screws, welds, and adhesives.

- Attaches top sheets as thin as 0.2 mm/ .008″.

- Clinches into base panel as hard as HRB 45 / HB 84.

- Tapered and interference fit minimize hole tolerance issues.

- For use in stainless steel and higher strength aluminum alloy sheets.

microPEM® Self-Clinching TackScrew™ Fasteners

Designed for Sheet-to-Sheet Attachment

- Simple, press-in installation for secure attachment.

- Twist out (unscrews) if removal is necessary.

- Replaces micro screws, eliminating installation issues.

- If removed, fastener can be reinstalled one time using permanent thread locking adhesive.

- Can be installed automatically for high volume applications.

microPEM® Self-Clinching Locating Pins

Install Into Thin Sheets For Locating/Positioning Applications

- Smallest diameter: 1 mm / .040″.

- Shortest length: 2 mm / .080″.

- Minimum sheet thickness: 0.5 mm / .020″.

- Maximum sheet hardness: HRB 92.

- Fastener material: steel, stainless steel and aluminum.

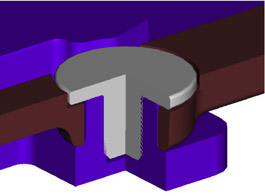

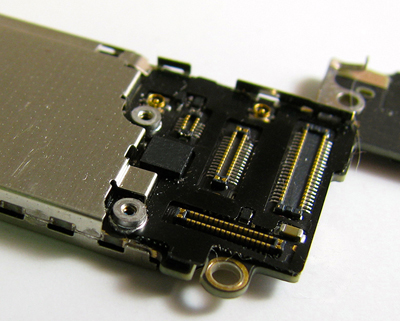

Types MSO4™ / MSOFS™ microPEM® Standoffs

MSO4™ self-clinching installation

- Smallest thread size: M1.0 / #0-80.

- Shortest length: 1 mm / .040″.

- Minimum sheet thickness: 0.3 mm / 0.012″.

- Maximum sheet hardness: HRB 88.

- Fastener material: Steel, Stainless steel, aluminum

MSOFS™ flaring installation

- Smallest thread size: M1.0 / #0-80.

- Shortest length: 2 mm / .093″.

- Sheet thickness: 0.2 – 0.3 mm / 0.008 – 0.012″.

- Maximum sheet hardness: None, use any panel

- Fastener material: stainless steel.

microPEM® SMT Spacers

Attaches to P.C. Board for Nut/Spacer applications

- Hex shaped barrel provides larger solder area.

- Provided on tape and reel.

- Reduces board handling.

- Smallest thread size: M1 / #0-80.

- Minimum sheet thickness 0.5 mm / .020″.

- RoHS compliant.

microPEM® Screws

- Smallest thread size: M0.8.

- Shortest length: 1 mm / .039″.

- Fastener material: steel, stainless steel and aluminum.

- Driver types: TORX®/TORX Plus® / cross-recess / internal hex.

- Head styles: flat head / pan head / socket-head / wafer-head.

- Special features: Locking patch, REMFORM®, TAPTITE 2000®, FASTITE 2000®, PT® and DELTA PT®.

- Platings: zinc, nickel, black nickel and black oxide.

microPEM® Threaded Inserts

- Threads as small as M1.

- Designed for use in straight or tapered holes.

- Symmetrical design eliminates the need for orientation.

- Provides excellent performance in wide range of plastics.

- Fastener material: brass / aluminum / stainless steel.

- Styles: ultrasonic, thermal press in.

Cost Saving microPEM® Fasteners

What are your costs to design in a screw?

- Cost of Screw

- Cost of patch to prevent loosening

- Cost of threaded insert or tapped hole

- Cost of installation time - screw vs. press

- Cost of rework due to cross-threading

- Cost of driver bits

- Cost of rework due to drive bit "cam-out"

Are these variables less than $7 per 1,000-$12 per 1,000?

TackPin® may be the answer.

View the side by side comparison of TackPin™ and screw installation.

microPEM® Nuts and Standoffs simplify attachments

SMTSO

microPEM® SMTSO Surface Mount Micro Fasteners simplify attachment.

MSO4 Standoff Replaces Weld Fasteners

M1.4 standoff clinched into 0.4mm / .016″ stainless.

microPEM® TackSert® Fasteners

Screw or swaged pin could be converted to a TackSert™ reducing installation complexity