Using 3D Technology to Conceptualize New Fasteners

Investment in 3D Printing Solutions Delivers Faster Designs to Customers

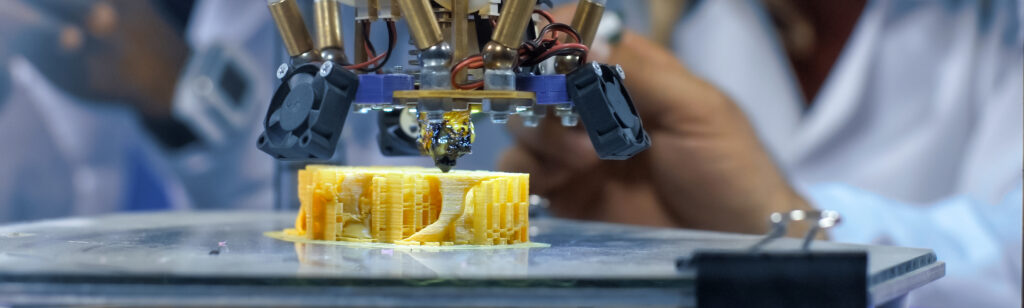

New product development is a critical part of the work we do here at PEM® Europe and at all our facilities around the world. The recent addition of 3D printing technology at our Galway location is enabling our teams to bring 3D CAD data to life and generate conceptual models for current and future customers.

Operational since 2021, our 3D printer comes from Ultimaker, the market leader in desktop 3D printing. The printer is capable of printing two materials simultaneously, including metallic materials.

Our engineering teams are also experimenting with new material types, including metallic, to bring even more capabilities to our 3D investment.

While 3D printing has existed for some time, the technology has become much more advanced in recent years and more accessible for use across a variety of applications. As a result, more companies are utilizing 3D innovation because of the many advantages it offers:

- Cost-saving alternative to other manufacturing methods

- Faster product development

- Greater design flexibility

- More efficient product testing

- Improved part/product quality

- Sustainability

Using 3D technology to take a fastener design idea from concept to a physical prototype is just one of the many ways our team delivers innovation to our customers. To learn more about partnering with PEM® Europe for your next fastener challenge, contact our engineering team today.