Fasteners for Stainless Steel Panels

If your application requires that the fastener clinches into stainless steel, be sure you use the fasteners specifically designed for this purpose.

There are many PEM® fastener choices that are appropriate for use with stainless steel panels. Perhaps the most important requirement for using a clinch fastener is that it must be harder than the mating panel to ensure the fastener deforms the panel.

Maximum Sheet Hardness for Fastener Materials

| Fastener Material | Sheet Hardness |

|---|---|

| Aluminum | <HRB 50 / HB 89 |

| Unhardened Steel | <HRB 60 / HB 107 |

| 300 Series Stainless Steel | <HRB 70 / HB 125 |

| Hardened Steel | <HRB 80 / HB 150 |

| Hardened Stainless Steel | <HRB 88 (92) / HB 183 (202) |

Typical Hardness of Sheet Materials

| Sheet Material | Sheet Hardness |

|---|---|

| 5052-H32/34 Aluminum | HRB 15-30 / HB |

| Cold-rolled Steel | HRB 40-75 / HB |

| 6061-T6 Aluminum | HRB 50-55 / HB 89-96 |

| 304 Stainless Steel (Annealed) | HRB 80+ / HB 150+ |

| HSLA Steel | HRB 80-85 / HB 150-169 |

Typical Sheet Hardness and the Appropriate PEM® Fastener

UNS Designation Maximum Sheet Hardness per ASTM A240

| Type | Type | PEM® Part |

|---|---|---|

| HRB 88 Maximum | S30500 S40500 S40910 S40920 S40930 S40945 S40977 S41045 S42035 | A4™ LA4™ F4™ SO4™ BSO4™ TSO4™ PFC4™ SFP™ |

| HRB 90 Maximum | N08700 N08904 S30435 S41050 S41008 S42900 S43000 S43035 | SP™ SMPP™ |

| HRB 92 Maximum | S20432 S30200 S30400 S30403 S30409 S30441 S30530 S34700 S34709 SS34751 S34800 S34809 S40975 | FH4™ FHP™ TP4™ |

Installation

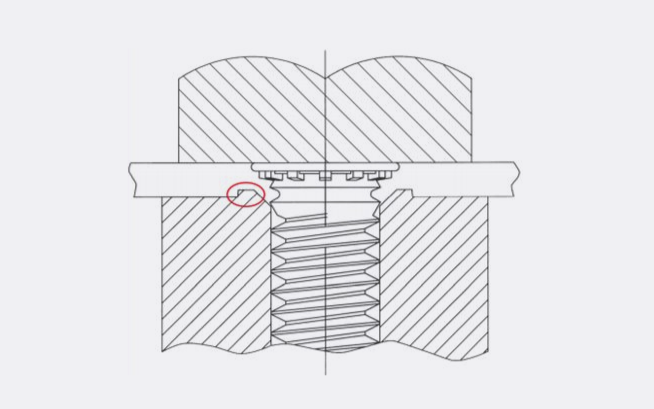

When installing into stainless steel sheets, cold working is an important phenomenon to understand. Local hardening of the material when pressure is applied to an area is the result of cold working. The installation of clinch fasteners involves cold working the sheet metal into the clinch features of the fastener.

As this happens, the stainless steel sheet hardens locally around the fastener. This actually makes it harder for the fastener to install because, as discussed earlier, the fastener must be hard enough to clinch into the sheet. Thin stainless steel sheets are especially of interest in this case, because they have been rolled more than thicker sheets, and therefore have more cold work. In some cases, such as FH4™ and FHP™ studs in the PEM® SS Data Sheet, a raised-ring anvil is recommended for installation.

400 Series vs A286

A note about 400 Series Fasteners for Stainless Steel Panels

In order for self-clinching fasteners to work properly, the fastener must be harder than the sheet into which it is being installed. In the case of stainless steel panels, fasteners made from 300 Series Stainless Steel do not meet these hardness criteria.

It is for this reason the 400 Series fasteners are offered (A4, LA4, F4, SO4, BS04, TSO4, FH4, TP4, and PFC4).

However, while these 400 Series fasteners install and perform well in 300 Series stainless steel sheets they should not be used if the end product:

- Will be exposed to any appreciable corrosive presence

- Requires non-magnetic fasteners

- Will be exposed to any temperatures above 300F (149C)

Nickel Plated 400 Series Standoffs

- Improved corrosion resistance for stainless steel applications

- Standoffs allow for stacking or spacing in applications where corrosion resistance is required

- Fasteners clinch securely into stainless steel sheet with hardness up to HRB 88 / HB 183

- Available with blind or through-hole threads. Closed threads provide a flush appearance on backside of the sheet

- Nickel plating presents an attractive finish to enhance the overall assembly appearance

- For complete specifications and installation, data see PEM® data sheet SO

Magnetism

Magnetism is often a crucial property to consider when selecting a fastener. It is important to understand the differences in magnetic properties when discussing stainless steels and PH grade materials. All austenitic stainless steels are non-magnetic. However, they may become slightly magnetic after cold working. So, a cold formed 300 series fastener may actually be slightly magnetic.

Additionally, martensitic stainless steels are magnetic. Many 400 series stainless steels are martensitic, and therefore, magnetic. Some PH grade materials are magnetic, while some are not. A286, for example, is non-magnetic. Material traceability is important for one to understand the magnetic properties of a given stainless steel.

Use Cases

Mobile Phone

PEM® Solution:

MSO4™

Description:

This customer previously used weld fasteners. Following the introduction to MS04™ the next generation phone used 0.3mm aluminum chassis as they no longer needed similar materials for welding.

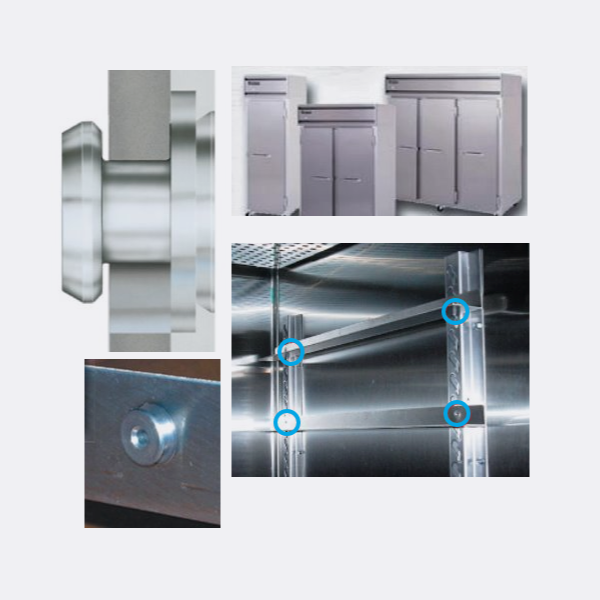

Adjustable Tray Rails

PEM® Solution:

SK4-F™ KEYHOLE® Fastener

Description:

The customer is using two custom KEYHOLE® standoffs per tray support rail in their line of commercial refrigerators. The tray rails attach to adjustable mounting slots on the frame of the refrigerator and the rails support food trays inside the unit. These standoffs replaced weld standoffs. The welding marred the finish on the stainless steel rails and the location of the standoffs was not as precise as that offered from pre-punching the holes and installing self-clinching standoffs.

X-Ray Image Processor

PEM® Solution:

SFP™ SpotFast®

Description:

This customer had already been using our FH4 studs, SP nuts and SO4 standoffs in their stainless chassis. Then they learned they could eliminate the costly weld spatter repairs they experienced by switching from spot-welding to clinching in a SFP SpotFast® fastener.

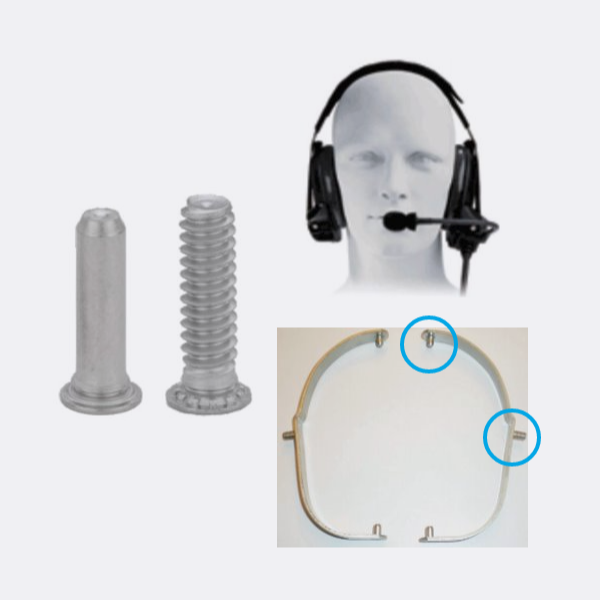

Headphones

PEM® Solution:

TP4™ pin and FH4™ stud

Description:

We were asked to provide fasteners for use in a heat treated stainless steel band, used to secure ear pieces to a military head set. An FH4-032-6 was used to secure each bracket to the main head band. The special TP4 was created to secure and act as a pivot point, for the ear pieces. Due to the narrow width of the band and the angle of the material, special tooling was needed to install the TP4 pins.