Fasteners for Magnesium and Aluminum Castings

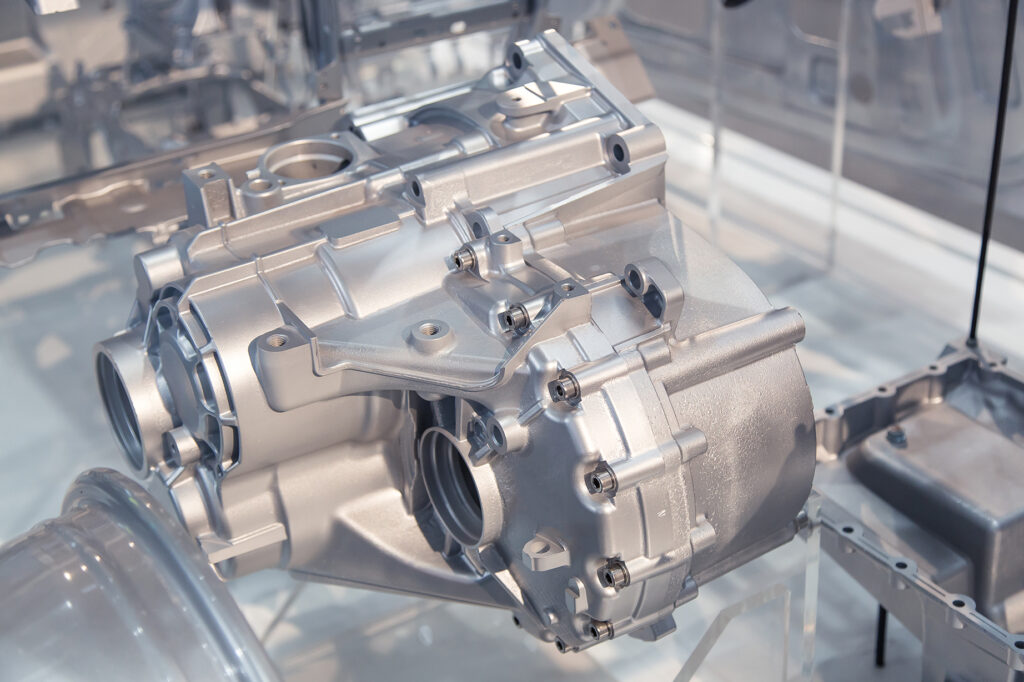

Why Magnesium or Aluminum Castings?

Intricate shapes can be created with a mold. This costs more upfront but saves in secondary efforts (drilling, milling, etc).

PEM® Broaching Nuts, Studs, and Standoffs can be used in Aluminum and Magnesium casting applications.

Magnesium

- Magnesium is the lightest of all structured materials and has excellent stiffness and strength-to-weight ratios.

- Outstanding EMI and RFI shielding properties, perfect for connectors or electrical housings.

- Utilized for medical and laboratory equipment to provide protection against other interfering signals in a hospital room.

Aluminum

- Creates lighter parts with more surface finishing options than other die cast alloys.

- Withstand the highest operating temperatures of all the die cast alloys.

- Corrosion resistant

- Retains high dimensional stability with thin walls and can be used in almost any industry

Magnesium or Aluminum Castings

Fastener Solutions

Because Magnesium and Aluminum materials are lighter you need a way to cut into the material. Broaching Nuts and Standoffs have knurled “teeth” that allow you to do this.

Internally Threaded Fasteners

| Product | Notes |

|---|---|

| CKS™ CASTSERT® Press-in Inserts | Strong Internal threads in large castings Can be installed without secondary machining Installed using an overhead press reducing installation time vs. tapping Knurled body for high torque resistance Flush with panel installation |

| KF2™ KFS2™ Broaching Nuts | |

| KFE™ and KFSE™ Broaching Standoffs | |

| KFB3™ For broaching and Flaring | |

| CFN™ Broaching Locknut | Thinner sheets Close-to-edge applications Prevailing torque locking element provides torque to eliminate loosening of mating threaded hardware |

| PEM® RT® Locknut can be added to a broaching nut | |

| MSOFS™ microPEM® Flaring Standoffs | Attach permanently in thin panels of any hardness including stainless steel No minimum sheet thickness Installed into any type or hardness panel (metal, plastic, PC Board) Flaring feature allows for captivation of multiple panels Fastener captivation method allows for reduced centerline-to-edge designs |

| SpinTite® AEL™ Low-Profile Head Inserts | Feature a large diameter, low-profile head and knurled shank Offers highest all around strength |

| SpinTite® AEK™ Minimized-Profiled Head Inserts | Same as AEL but minimized-profile head Near-flush installations with no need for special hole preparations such as countersinking or dimpling |

| AEH™ Half-Hex Shank Low Profile Head Inserts | Hex body design Improved torque-out resistance |

| Plus+Tite® Blind Threaded Inserts | Superior pullout resistance in plastics and thin sheet metal Internal formed threads are compatible with unified grade 5 or metric class 8.8 screws Shoulder provides self-locating feature All surfaces are plated for superior corrosion resistance |

| Hexagonal NFPA™ and NFPC™ Inserts | Press-fit insert provides strong, reusable threads. No heat or ultrasonic required Hexagonal “barbed” configuration ensures high torque-out and pullout values Aluminum inserts idea for light-weight designs Aluminum and stainless steel inserts offer lead-free alternative |

Externally Threaded Fasteners

| Product | Notes |

|---|---|

| KFH™ Broaching Studs | Ideal use for PC Boards and plastics but also works in Castings and Magnesium ET plated because it is expected for PC Boards and solder but it can be made with other finishes |

| SGP™ Swaging Collar Studs | Installs into sheets as thin as .024” / 0.6mm Can be used to attach dissimilar materials Can captivate multiple panels as long as the total thickness does not exceed the maximum sheet thickness Can be installed into most materials including stainless steel and rigid non-metallic panels Allows for close centerline-to-edge distance The fastener can deform which allows it to be installed into any type of panel |

| Press-In Studs | Typically for Plastics but also work in Castings and Magnesium Mounting components onto external threads Lengths 3/6” to 1” (4.76 to 25.4mm) Available in aluminum, brass, steel, and stainless steel Can be installed into pre-molded or drilled holes without the use of heat or ultrasonics |

Captive Panel Screws

| Product | Notes |

|---|---|

| PFK™ Broaching Captive Panel Screws | Ideal use for PC Boards and plastics Broaching feature allows it to broach into Cast aluminum or Magnesium |

| PF11MF™ PF11MW™ (Floating) PF7MF™ Flare-Mounted Captive Panel Screws | The fastener can deform which allows it to be installed into any type of panel Works with in Casting situations |

Screw Replacements

| Product | Notes |

|---|---|

| TKA™ TK4™ microPEM® TackSert® Pins | Installation into Plastics, Metal Castings, other brittle materials Simple press-in installation (does not require heat or ultrasonics) eliminates many costs and concerns associated with micro screws: Cross threading, Use of inserts/tapping, Tightening torque control, Vibrational back-out Low profile head provides space savings Tapered tip aligns fastener in hole Easily installed automatically |

Other Styles

| Product | Notes |

|---|---|

| SFK™ SpotFast® Clinch/Broach Mount Fasteners | Holds two panels together Can hold two panels together that are not like materials |

| KSSB™ Broaching Snap-Top® Standoffs | Ideal use for PC Boards and plastics Broaching feature allows it to broach into Cast aluminum or Magnesium Broaches into bottom material due to knurled tip |

| microPEM® ClampDisk™ Fastener | 1mm Pin can be designed into the casting mold and enable the use of ClampDisk™ to replace loose screws Presses straight onto a 1mm pin to replace threads, adhesive, rivets and other small fasteners Upward flanges of the disk grip onto the pin and prevent push-off while the download flanges flex and generate clamp load Simple installation Removability Works with multiple panels of any type Limited installation stress to assemble Tamper-evident |

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Email: [email protected]

U.S. 1-866-236-4063

Europe: 353-91-747100

China: 86-21-5868-3688

Singapore: 65-6-745-0660