T4-10-025

TYPE T4™ microPEM® TackPin® Fasteners

T4-10-025

TYPE T4™ microPEM® TackPin® Fasteners

New self-clinching microPEM® TackPin® (Type T4™)fasteners are ideal for installation into stainless steel and higher strength aluminum alloy sheets. They are for use in compact electronic assemblies enabling sheet-to-sheet attachment, replacing costly screw installation in applications wheredisassembly is not required. TackPin® fasteners eliminate typical screw-relatedissues (including tapping, cross-threading, torque control, and vibration backout)and ultimately promotes quick and easy installation with minimal hardware.TackPin® fasteners can provide a good alternative to welds or adhesives.

Features and Benefits

- Advantages over micro screws: eliminates costly tapping, cross threading, torque control, vibrationback-out and installation time.

- Interference fit minimizes hole tolerance issues.

- Tapered tip assists location.

- Low-profile head provides space savings.

- Can be installed automatically.

- For use in stainless steel and higher strength aluminum alloy sheets..

Especificaciones

- Material del inserto

- Acero inoxidable serie 400, Acero inoxidable endurecido serie 400

- Acabado Estandard

- Pasivado y/o probado, Pasivado y/o probado según ASTM A380

- Para uso en láminas de dureza

- HRB 88 or Less (Hardness Rockwell “B” Scale)

HB 183 or Less (Hardness Brinell) - Categoría del producto

- PEM Type T4™ Self-clinching microPEM® TackPin® for Installing Into Stainless Steel

- Proveedor CAD

- PennEngineering® (PEM®)

- Identificación de pieza CAD

- 106440

- Tipo de aplicación

- Electrónica automotriz

- Material del panel base

- Aluminio, Acero endurecido, Acero inoxidable , Acero

- Marca

- microPem

- Características del inserto

- Micro

- Industria

- Electrónica de consumo

- Equipo/método de instalación

- Alimentador manual con soporte en C

- Producto de la familia PEM

- MPF

- Tipo de producto

- Pines

- Tipo de tecnología

- Auto-clinchado

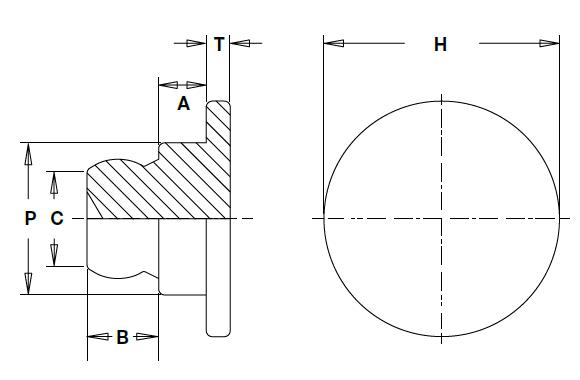

- A ± 0.025mm/±.001in_in

- .016in

- A ± 0.025mm/±.001in_mm

- 0.406mm

- B ± 0.075mm/±.003in_in

- .024in

- B ± 0.075mm/±.003in_mm

- 0.610mm

- Base Panel Hole Size -0.05mm/ -.002in_in

- .040in

- Base Panel Hole Size -0.05mm/ -.002in_mm

- 1.02mm

- Base Panel Hole Size Code

- 10

- Base Panel Min. Sheet Thickness_in

- .035in

- Base Panel Min. Sheet Thickness_mm

- 0.89mm

- H ± 0.1mm/±.004in_in

- .079in

- H ± 0.1mm/±.004in_mm

- 2mm

- Min. Dist. Hole C/L to Edge_in

- .039in

- Dist. Mín orificio cercano al borde_mm

- 1mm

- C Max._in

- .035in

- C Máx._mm

- 0.89mm

- P ± 0.05mm/±.002in_in

- .051in

- P ± 0.05mm/±.002in_mm

- 1.3mm

- T ± 0.1mm/±.004in_in

- .008in

- T ± 0.1mm/±.004in_mm

- 0.2mm

- Top Sheet Hole Size ± 0.05mm/± .002in_in

- .058in

- Top Sheet Hole Size ± 0.05mm/± .002in_mm

- 1.47mm

- Top Sheet Thickness Code

- 025

- Top Sheet Thickness_in

- .008 to .011in

- Top Sheet Thickness_mm

- 0.2 to 0.28mm

Recursos

Datos de instalación y rendimiento

| TYPE | TEST PIN MATERIAL | INSTALLATION (kN) | PULL-OFF (N) | CLAMP LOAD (N) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CDS-100 | 6061-T6 Aluminum | 0.33 | 18.1 | 7 |

| TYPE | PIN DIAMETER CODE | TEST SHEET THICKNESS | INSTALLATION (kN) | PUSHOUT (N) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MPP | 1MM | 0.5mm Stainless Steel HRB 88 | 10 | 320 | ||||||

| MPP | 1.5MM | 0.5mm Stainless Steel HRB 88 | 12 | 760 | ||||||

| MPP | 2MM | 0.5mm Stainless Steel HRB 88 | 18 | 860 |

| TYPE | THREAD CODE | MAX. REC. TIGHTENING TORQUE FOR MATING SCREW (N•m)) | SHEET THICKNESS (mm) | TEST SHEET MATERIAL | INSTALLATION (kN) | PUSHOUT (N) | TORQUE-OUT (N•m) | PULL-THRU (N) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| MSO4 | M1 | 0.019 | 0.3 | 300 Series Stainless Steel | 11.1 | 150 | 0.15 | 350 | ||

| MSO4 | M1 | 0.019 | 0.43 | 300 Series Stainless Steel | 11.1 | 200 | 0.25 | 350 | ||

| MSO4 | M1.2 | 0.036 | 0.3 | 300 Series Stainless Steel | 11.1 | 150 | 0.15 | 350 | ||

| MSO4 | M1.2 | 0.036 | 0.43 | 300 Series Stainless Steel | 11.1 | 200 | 0.25 | 350 | ||

| MSO4 | M1.4 | 0.057 | 0.3 | 300 Series Stainless Steel | 11.1 | 150 | 0.15 | 350 | ||

| MSO4 | M1.4 | 0.057 | 0.43 | 300 Series Stainless Steel | 11.1 | 200 | 0.25 | 350 | ||

| MSO4 | M1.6 | 0.084 | 0.3 | 300 Series Stainless Steel | 11.1 | 150 | 0.15 | 350 | ||

| MSO4 | M1.6 | 0.084 | 0.43 | 300 Series Stainless Steel | 11.1 | 200 | 0.25 | 350 | ||

| MSO4 | M2 | 0.175 | 0.3 | 300 Series Stainless Steel | 11.1 | 150 | 0.25 | 500 | ||

| MSO4 | M2 | 0.175 | 0.43 | 300 Series Stainless Steel | 11.1 | 200 | 0.3 | 500 |

| TYPE | THREAD CODE | MAX. REC. TIGHTENING TORQUE FOR MATING SCREW (in. lbs.) | SHEET THICKNESS (in.) | TEST SHEET MATERIAL | INSTALLATION (lbs.) | PUSHOUT (lbs.) | TORQUE-OUT (in. lbs.) | PULL-THRU (lbs.) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| MSO4 | 080 | 0.65 | 0.013 | 300 Series Stainless Steel | 2500 | 33 | 1.3 | 78 | ||

| MSO4 | 080 | .65 | 0.017 | 300 Series Stainless Steel | 2500 | 45 | 2.2 | 78 | ||

| MSO4 | 256 | 1.3 | 0.013 | 300 Series Stainless Steel | 2500 | 33 | 2.2 | 110 | ||

| MSO4 | 256 | 1.3 | 0.017 | 300 Series Stainless Steel | 2500 | 45 | 2.6 | 110 |

| TYPE | THREAD CODE | LENGTH CODE | TEST SHEET THICKNESS & MATERIAL | PULLOUT (N) | TORQUE-OUT (N•cm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| MSIA/MSIB | M1 | 100 | ABS | 50 | 3.5 | |||||

| MSIA/MSIB | M1 | 250 | ABS | 150 | 10 | |||||

| MSIA/MSIB | M1.2 | 100 | ABS | 50 | 3.5 | |||||

| MSIA/MSIB | M1.2 | 250 | ABS | 150 | 10 | |||||

| MSIA/MSIB | M1.4 | 150 | ABS | 100 | 15 | |||||

| MSIA/MSIB | M1.4 | 300 | ABS | 330 | 30 | |||||

| MSIA/MSIB | M1.6 | 150 | ABS | 100 | 15 | |||||

| MSIA/MSIB | M1.6 | 300 | ABS | 330 | 30 | |||||

| MSIA/MSIB | M2 | 300 | ABS | 335 | 35 | |||||

| MSIA/MSIB | M2 | 400 | ABS | 470 | 40 | |||||

| MSIA/MSIB | M1 | 100 | Polycarbonate | 50 | 4.5 | |||||

| MSIA/MSIB | M1 | 250 | Polycarbonate | 200 | 12 | |||||

| MSIA/MSIB | M1.2 | 100 | Polycarbonate | 50 | 4.5 | |||||

| MSIA/MSIB | M1.2 | 250 | Polycarbonate | 200 | 12 | |||||

| MSIA/MSIB | M1.4 | 150 | Polycarbonate | 140 | 15 | |||||

| MSIA/MSIB | M1.4 | 300 | Polycarbonate | 400 | 30 | |||||

| MSIA/MSIB | M1.6 | 150 | Polycarbonate | 140 | 15 | |||||

| MSIA/MSIB | M1.6 | 300 | Polycarbonate | 400 | 30 | |||||

| MSIA/MSIB | M2 | 300 | Polycarbonate | 410 | 33 | |||||

| MSIA/MSIB | M2 | 400 | Polycarbonate | 595 | 35 |

| TYPE | THREAD CODE | MAX. REC. TIGHTENING TORQUE FOR MATING SCREW (N•m) | TEST SHEET THICKNESS & MATERIAL | INSTALLATION (kN) | PUSHOUT (N) | TORQUE-OUT (N•m) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| MSOFS | M1 | 0.019 | 0.2 mm 300 Series Stainless Steel | 6.67 | 311 | 0.146 | ||||

| MSOFS | M1.2 | 0.036 | 0.2 mm 300 Series Stainless Steel | 6.67 | 311 | 0.146 | ||||

| MSOFS | M1.4 | 0.057 | 0.2 mm 300 Series Stainless Steel | 6.67 | 311 | 0.146 | ||||

| MSOFS | M1.6 | 0.084 | 0.2 mm 300 Series Stainless Steel | 8 | 406 | 0.146 | ||||

| MSOFS | M2 | 0.175 | 0.2 mm 300 Series Stainless Steel | 8 | 406 | 0.146 |

| TYPE | THREAD CODE | MAX. REC. TIGHTENING TORQUE FOR MATING SCREW (in. lbs.) | TEST SHEET THICKNESS & MATERIAL | INSTALLATION (lbs.) | PUSHOUT (lbs.) | TORQUE-OUT (in. lbs.) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| MSOFS | 080 | 0.65 | .008" 300 Series Stainless Steel | 1500 | 69.8 | 1.29 | ||||

| MSOFS | 256 | 1.3 | .008" 300 Series Stainless Steel | 1800 | 91.2 | 1.29 |

| TYPE | SHEET THICKNESS & MATERIAL | PUSHOUT (N) | TORQUE-OUT (N•m) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SMTSO-080 | .062" Single Layer RF-4 | 378.7 | 0.56 | |||||||

| SMTSO-M1 | .062" Single Layer RF-4 | 378.7 | 0.56 | |||||||

| SMTSO-M1.2 | .062" Single Layer RF-4 | 378.7 | 0.56 | |||||||

| SMTSO-M1.4 | .062" Single Layer RF-4 | 378.7 | 0.56 | |||||||

| SMTSO-M1.6 | .062" Single Layer RF-4 | 378.7 | 0.56 |

| TYPE | SHEET THICKNESS & MATERIAL | PUSHOUT (lbs.) | TORQUE-OUT (in. lbs.) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SMTSO-080 | .062" Single Layer RF-4 | 85.1 | 4.94 | |||||||

| SMTSO-M1 | .062" Single Layer RF-4 | 85.1 | 4.94 | |||||||

| SMTSO-M1.2 | .062" Single Layer RF-4 | 85.1 | 4.94 | |||||||

| SMTSO-M1.4 | .062" Single Layer RF-4 | 85.1 | 4.94 | |||||||

| SMTSO-M1.6 | .062" Single Layer RF-4 | 85.1 | 4.94 |

| TYPE | SHEET MATERIAL | INSTALLATION (N) | PULLOUT (N) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T4-10-025 | 300 Series Stainless Steel | 2020 | 200 | |||||||

| T4-10-050 | 300 Series Stainless Steel | 2020 | 200 |

| TYPE | SHEET MATERIAL | INSTALLATION (lbs.) | PULLOUT (lbs.) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T4-10-025 | 300 Series Stainless Steel | 455 | 45 | |||||||

| T4-10-050 | 300 Series Stainless Steel | 455 | 45 |

| TYPE | SHEET MATERIAL | INSTALLATION (kN) | PULLOUT (N) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TA-10-025 | 5052-H34 Aluminum | 820 | 80 | |||||||

| TA-10-050 | 5052-H34 Aluminum | 820 | 80 | |||||||

| TA-10-075 | 5052-H34 Aluminum | 820 | 80 |

| TYPE | SHEET MATERIAL | INSTALLATION (lbs.) | PULLOUT (lbs.) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TA-10-025 | 5052-H34 Aluminum | 185 | 18 | |||||||

| TA-10-050 | 5052-H34 Aluminum | 185 | 18 | |||||||

| TA-10-075 | 5052-H34 Aluminum | 185 | 18 |

| TYPE | SHEET MATERIAL | INSTALLATION (N) | PULLOUT (N) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TFA-10-025 | 5052-H34 Aluminum | 450 | 40 | |||||||

| TFA-10-035 | 5052-H34 Aluminum | 450 | 40 | |||||||

| TFA-10-045 | 5052-H34 Aluminum | 450 | 40 | |||||||

| TFA-10-055 | 5052-H34 Aluminum | 450 | 40 |

| TYPE | SHEET MATERIAL | INSTALLATION (lbs.) | PULLOUT (lbs.) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TFA-10-025 | 5052-H34 Aluminum | 101 | 9 | |||||||

| TFA-10-035 | 5052-H34 Aluminum | 101 | 9 | |||||||

| TFA-10-045 | 5052-H34 Aluminum | 101 | 9 | |||||||

| TFA-10-055 | 5052-H34 Aluminum | 101 | 9 |

| TYPE | TEST BASE PANEL MATERIAL | DEPTH OF ENGAGEMENT (mm) | INSTALLATION (N) | PULLOUT (N) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TKA-10 | ABS | 0.8 | 133 | 9 | ||||||

| TKA-10 | ABS | 1 | 133 | 14 | ||||||

| TKA-10 | ABS | 1.3 | 133 | 19 | ||||||

| TKA-10 | ABS | 1.5 | 178 | 24 | ||||||

| TKA-10 | ABS | 1.8 | 178 | 31 | ||||||

| TKA-10 | ABS | 2 | 222 | 35 | ||||||

| TKA-10 | ABS | 2.3 | 222 | 41 | ||||||

| TKA-10 | ABS | 2.8 | 245 | 53 | ||||||

| TKA-10 | Polycarbonate | 0.8 | 222 | 25 | ||||||

| TKA-10 | Polycarbonate | 1 | 267 | 37 | ||||||

| TKA-10 | Polycarbonate | 1.3 | 267 | 53 | ||||||

| TKA-10 | Polycarbonate | 1.5 | 311 | 68 | ||||||

| TKA-10 | Polycarbonate | 1.8 | 334 | 86 | ||||||

| TKA-10 | Polycarbonate | 2 | 378 | 98 | ||||||

| TKA-10 | Polycarbonate | 2.3 | 400 | 113 | ||||||

| TK4-10 | Polycarbonate | 2.8 | 423 | 146 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.8 | 445 | 29 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 1 | 489 | 43 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 1.3 | 534 | 61 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 1.5 | 578 | 78 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 1.8 | 623 | 99 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 2 | 667 | 113 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 2.3 | 712 | 131 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 2.8 | 801 | 169 |

| TYPE | TEST BASE PANEL MATERIAL | DEPTH OF ENGAGEMENT (in.) | INSTALLATION (lbs.) | PULLOUT (lbs.) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TKA-10 | ABS | 0.0315 | 30 | 2 | ||||||

| TKA-10 | ABS | 0.0394 | 30 | 3 | ||||||

| TKA-10 | ABS | 0.0492 | 30 | 4 | ||||||

| TKA-10 | ABS | 0.0590 | 40 | 6 | ||||||

| TKA-10 | ABS | 0.0708 | 40 | 7 | ||||||

| TKA-10 | ABS | 0.0787 | 50 | 8 | ||||||

| TKA-10 | ABS | 0.0886 | 50 | 9 | ||||||

| TKA-10 | ABS | 0.1102 | 55 | 12 | ||||||

| TKA-10 | Polycarbonate | 0.0315 | 50 | 6 | ||||||

| TKA-10 | Polycarbonate | 0.0394 | 60 | 8 | ||||||

| TKA-10 | Polycarbonate | 0.0492 | 60 | 12 | ||||||

| TKA-10 | Polycarbonate | 0.0590 | 70 | 15 | ||||||

| TKA-10 | Polycarbonate | 0.0708 | 75 | 19 | ||||||

| TKA-10 | Polycarbonate | 0.0787 | 85 | 22 | ||||||

| TKA-10 | Polycarbonate | 0.0886 | 90 | 25 | ||||||

| TK4-10 | Polycarbonate | 0.1102 | 95 | 33 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.0315 | 100 | 7 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.0394 | 110 | 10 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.0492 | 120 | 14 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.0590 | 130 | 18 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.0708 | 140 | 22 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.0787 | 150 | 25 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.0886 | 160 | 29 | ||||||

| TK4-10 | Magnesium Casting (AZ91D) | 0.1102 | 180 | 38 |

| TYPE | TESTED TOP SHEET THICKNESS | SHEET MATERIAL | INSTALLATION (N) | PULLOUT (N) | TORQUE TO REMOVE (N•cm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| TS4-10-025 | 0.254 mm / .01" | 5052-H34 Aluminum HRB 63 / HB 114 | 556 | 80 | 3.3 | |||||

| TS4-10-050 | 0.533 mm / .021" | 5052-H34 Aluminum HRB 63 / HB 114 | 556 | 80 | 3.3 | |||||

| TS4-10-025 | 0.254 mm / .01" | 304 Stainless Steel HRB 89/HB 187 | 1423 | 125 | 4.6 | |||||

| TS4-10-050 | 0.533 mm / .021" | 304 Stainless Steel HRB 89/HB 187 | 1423 | 125 | 4.6 |

| TYPE | TESTED TOP SHEET THICKNESS | SHEET MATERIAL | INSTALLATION (lbs.) | PULLOUT (lbs.) | TORQUE TO REMOVE (in. oz.) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| TS4-10-025 | 0.254 mm / .01" | 5052-H34 Aluminum HRB 63 / HB 114 | 125 | 18 | 4.7 | |||||

| TS4-10-050 | 0.533 mm / .021" | 5052-H34 Aluminum HRB 63 / HB 114 | 125 | 18 | 4.7 | |||||

| TS4-10-025 | 0.254 mm / .01" | 304 Stainless Steel HRB 89/HB 187 | 320 | 28 | 6.5 | |||||

| TS4-10-050 | 0.533 mm / .021" | 304 Stainless Steel HRB 89/HB 187 | 320 | 28 | 6.5 |

Inventario

| Distribuidor | Cantidad | Contacto | Teléfono | Dirección | Ubicaciones |

|---|