Components Compilation

From failure analysis testing to materials testing, we can determine the safety, compliance, and application suitability of your parts

kicker

In-page header element with large H2

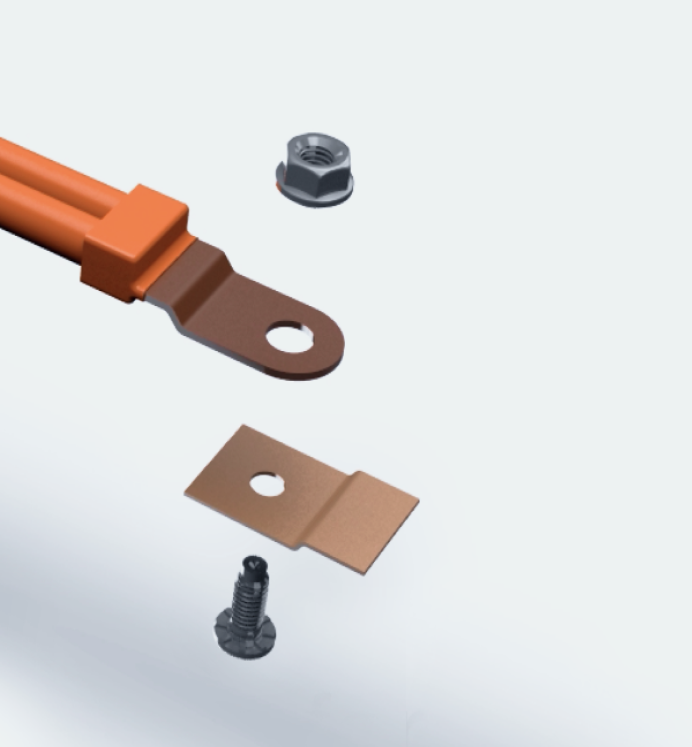

Progressive in-die mechanically attached fasteners are a cost-saving alternative for the application of sheet stamping parts with projection welded nuts. In addition to cost savings, mechanically attached fasteners that are installed in-die offer many other advantages over conventional weld fasteners including the ability to fasten to dissimilar materials, water-tight seals, stronger joints, reduced weight, and no coating or KTL effect.

Discover the cost-effective and superior performing fastener alternative to welding. PROFIL® Mechanically Attached Fasteners (MAF) offer many advantages over conventional weld fasteners – from greater design flexibility to the ability to integrate into a customer’s in-die process.

Tabbed Content Feature

Electric Vehicles

PEM® develops nuts and studs which are fastened to metal parts or panels by means of a riveting, piercing or and assembly line solutions to meet the individual production requirements of its customers.

Mounting Applications

Body Panels

Instrument Panels

Safety Systems

Seating

Controls

Closures

Product Comparison

| Benefits | Haeger® | Weld |

|---|---|---|

| Cost-Saving Installation | Single-step in-die installation capability eliminates secondary operations, increases throughput, cuts costs | Secondary operations require more manufacturing time and energy consumption |

| Fasten Dissimilar Materials | Able to be fastened into several materials like common steel, HSS, sandwich panels, hot forming steel, aluminum, magnesium, die-cast material, carbon fiber | Able to be fastened into several materials like common steel, HSS, sandwich panels, hot forming steel, aluminum, magnesium, die-cast material, carbon fiber |

| Water-Tight Seals | Creates a reliable leak-proof seal in aluminum and steel applications, preventing water intrusion | Water-tight seals are difficult to achievewith weld fasteners, leading to water damage and corrosion from elements |

| Stronger Joints | The lack of a heat source (required for a weld fastener) produces no weak points due to thermal effect | The welding process increases chance for thermal stress or annealing |

| Reduced Weight | A mechanically attached nut is typically lighter than a weld nut while maintaining similar performance | The welding process adds additional weight to the vehicle |

| No Coating or KTL Effect | Can install a coated fastener into a panel without disturbing the coating or KTL of either part | Welding process burns off existing coatings and creates an opportunity for corrosion |

| Full-Service Technical Support | PROFIL® provides comprehensive support – applications engineering, tooling, manufacturing, training, tech support | Weld fastener manufacturers typically do not provide design and technical support |

Various Content Blocks

KICKER

Lorem Ipsum

Dolor Sit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

KICKER

Lorem Ipsum

Dolor Sit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

KICKER

Lorem Ipsum Dolor Sit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

Introduction

PEM® Busbar at a Glance

Lorem ipsum

Discover the cost-effective and superior performing fastener alternative to welding. PROFIL® Mechanically Attached Fasteners (MAF) offer many advantages over conventional weld fasteners – from greater design flexibility to the ability to integrate into a customer’s in-die process.

Integer maximus augue

Discover the cost-effective and superior performing fastener alternative to welding. PROFIL® Mechanically Attached Fasteners (MAF) offer many advantages over conventional weld fasteners – from greater design flexibility to the ability to integrate into a customer’s in-die process.

Neque viverra

Discover the cost-effective and superior performing fastener alternative to welding. PROFIL® Mechanically Attached Fasteners (MAF) offer many advantages over conventional weld fasteners – from greater design flexibility to the ability to integrate into a customer’s in-die process.

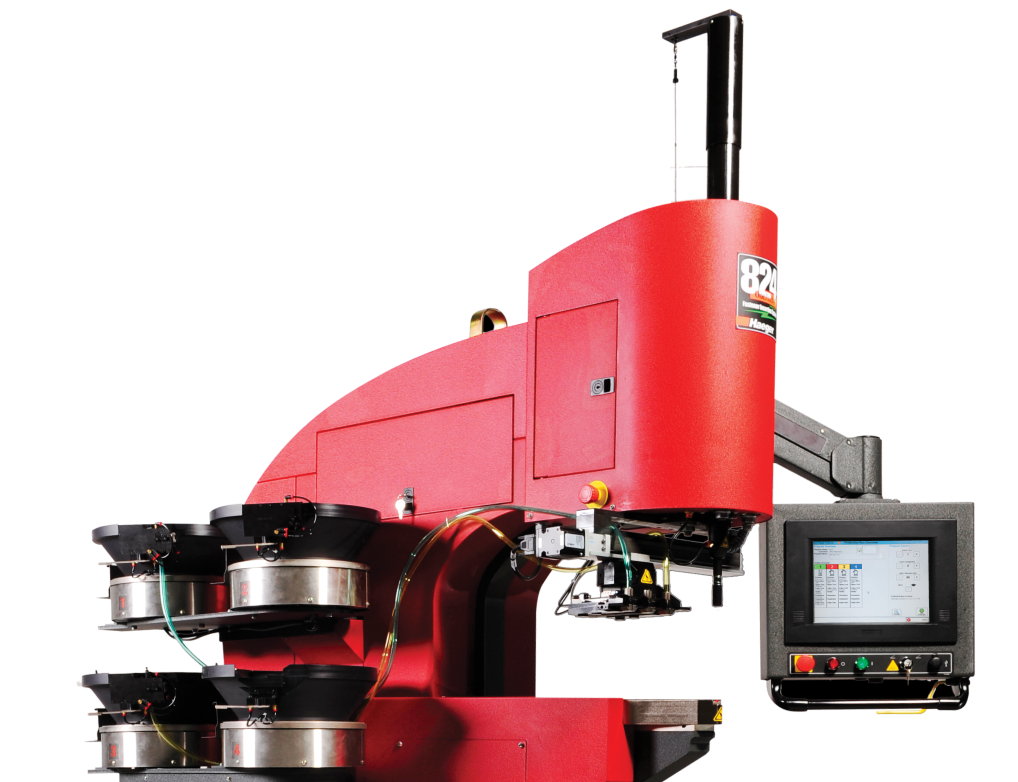

HAEGER® FASTENING SYSTEM

Your workflow

just evolved

Testimonial

Mikael BjorklundLorem ipsum dolor sit amet Global Product Availability and Supply, consectetur adipiscing elit, sed do eiusmod A2LA. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Chief Engineer, Manufacturing

Ericsson Consumer Products

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Not Your Spec?

Let’s Talk.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

case study

Helping Jaguar across the finish line.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

case study

Helping Jaguar across the finish line.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

lorem ipsum

Unified Solutions

150

Dolor sit amet consectetur

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor.A

25M

Lorem ipsum dolor sit amet,

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor.A

95%

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor.A

Help Center

Have a project?Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

section

The Process

1

Problem Definition Dolor Adipiscing Elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

2

Design Exploration gravida metus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

3

Design Optimization gravida metus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.

4

Design Optimization gravida metus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse at gravida metus, sit amet dapibus ex. Donec maximus lectus a tortor porttitor, id dictum tortor laoreet.