Automotive

Over 90% of the world’s top automakers trust the high-performance power of PEM®. Try our fasteners for yourself.

Critical Systems Fastening.

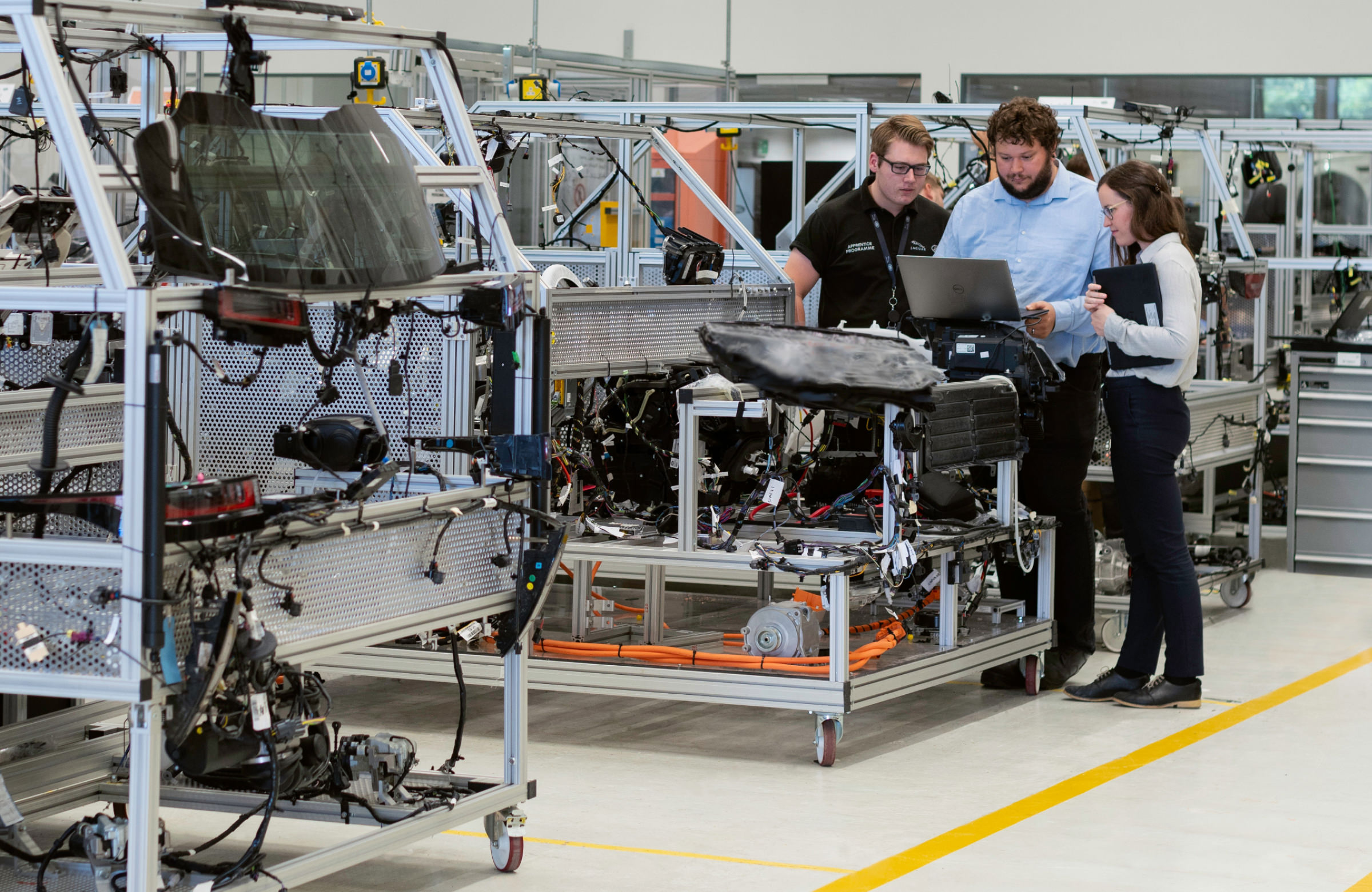

From heavy-duty fastening solutions for structural systems to precision-engineered micro fasteners and current carrying fasteners for automotive electronics, our expansive portfolio of innovative products for the automotive industry is unmatched.

From heavy-duty fastening solutions for structural systems to precision-engineered micro fasteners and current carrying fasteners for automotive electronics, our expansive portfolio of innovative products for the automotive industry is unmatched.

For critical automotive electronics applications, choose PEM® self-clinching fasteners. And for structural and body in white fastening applications, trust the innovation behind PROFIL® – a PennEngineering company and the world’s premier global manufacturer of Mechanically Attached Fasteners (MAF).

Over 90% of the world’s top automakers trust the high-performance power of PEM® and PROFIL® fastening solutions.

PEM® Fastening Solutions

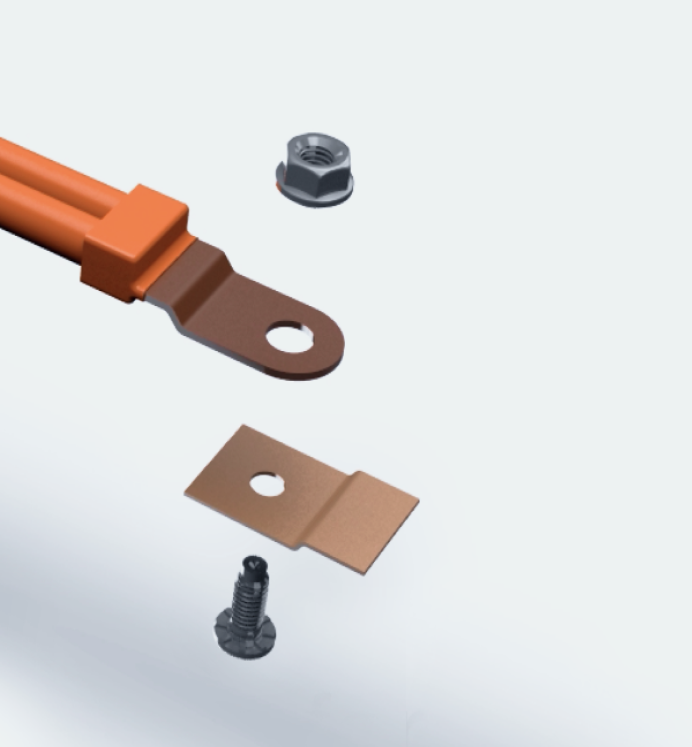

Self-Clinching Fasteners for Critical Automotive Electronics Applications

Powertrain

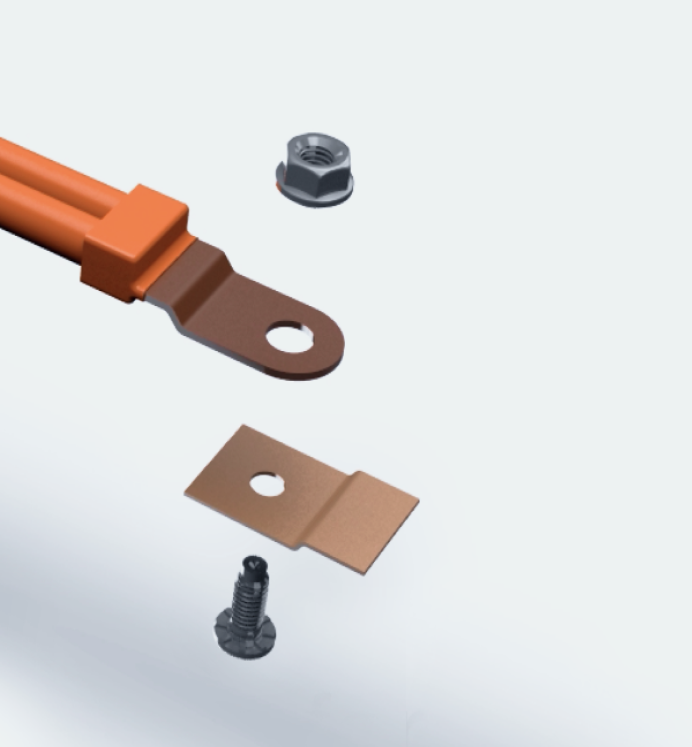

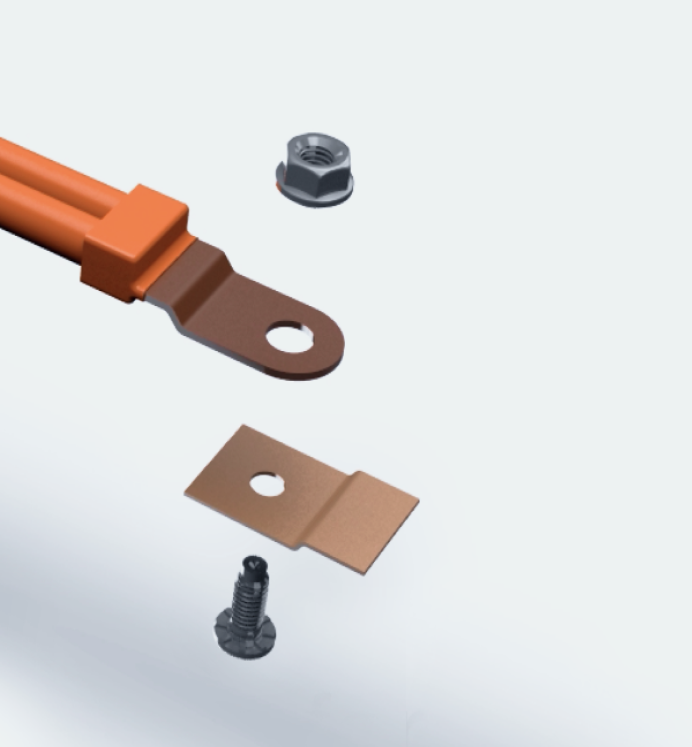

Busbar

Safety & ADAS

Body Electronics

Infotainment

PROFIL® Fastening Solutions

Mechanically Attached Fasteners for Structural and Body in White Fastening

automotive

By the Numbers

3.5%

Global automotive production growth

Global automotive production is expected to grow at a 3.5% CAGR over the next 5 years.

1M

Unique users

Nearly 1M unique users research PEM® products per year.

18,000

Unique consumers

Nearly 18,000 unique consumers of PEM® parts per year.

PEMEDGE® Services

Gain a market edge.

PEMedge® Services give you a full suite of expertise to improve your product’s cost, quality, time to market, and overall performance.

Teardown Service

- Complete Product Disassembly

- Assembly Structure Assessment

- Identify Alternative Fastening Solutions

- Alternative Fastener Replacement/Testing

- Teardown Report

- Identify Efficiencies/Implementation Plan

Testing Service

- FEA Analysis

- Mechanical Testing

- Tensile and Compression Strength

- Micro Hardness

- Fastener Joint Cross-Sectioning

- Corrosion and Plating Testing

APPLICATION ENGINEERING

- Complete Product Disassembly

- Assembly Structure Assessment

- Identify Alternative Fastening Solutions

- Alternative Fastener Replacement/Testing

- Teardown Report

- Identify Efficiencies/Implementation Plan

FASTENERCLASS™ MASTER CLASS

- Free Customized Training Sessions

- Learn from Global Experts

- Live, web-based, and pre-recorded training options available

Standard Classes Include:

- Theory, Best Practices, Application Exploration

- Intro to Self-Clinch Theory

- Proper Fasteners for Stainless Steel Panels

- Surface Mount Fastener Technology (SMT) vs. Broach

Designed for automotive.

PEM® products along with ATLAS® blind rivet nuts, and PROFIL® Mechanically Attached Fasteners (MAF) and installation systems are designed to take on the unique assembly challenges of the automotive and transportation markets.

help center

Have a project? Let’s get started.

Have an application question? Talk to a PEM® engineer and discover the most reliable, cost-effective fastening solution for your biggest challenge.

Request free product samples and see how our innovative fastener designs and technologies can help save you time, money, and resources.

Gain valuable insights from our extensive resources center. Includes product catalogs, CAD drawings, data sheets, videos, buyer guides, and more.

Find information on environmental and government compliance, quality approvals and certifications, and browse other regulatory resources.

Related Solutions

The Power to Connect

See how PEM® delivers engineering innovation with global services and capabilities that expand beyond the general automotive industry.

Automotive Electronics

Go above and beyond the ability of traditional screws for your automotive electronics applications. With PEM® fastening solutions, you get stronger, cleaner, more reliable performance – and faster time to market.

Our Top PEM® Automotive Electronics Fasteners

TK4™ TackSert® Pins

B™ Self-Clinching Blind Fasteners

THFE™ Heavy Duty Studs for Thin Sheet

EV and Charging

The future is electric – and the engineering excellence behind PEM® fastening solutions is why many of the world’s top brands turn to PEM® as they face new challenges in an increasingly electric world.

Proven Performance for EV Battery Trays

PROFIL® Rivet Nuts RND

PROFIL® Self-Pierce Rivet Studs SBF

PEM® HFE/HFH Heavy Duty Studs

ATLAS® Blind Rivet Nuts

SI® Inserts for Plastics

Automotive

Case Studies

microPEM® TackSert®

50% reduction in installation.

50% reduction in installation.

Switching from a thread forming M2 screw to a microPEM® TackSert® fastening solution exceeded this customer’s stringent requirements for a new camera system – and significantly reduced installation time, head height, and keep-out space.

PEM® SMT™ Standoff

Higher output, lower TIC.

In this power steering application, switching from a broaching fastener to a PEM® SMT™ Standoff increased production throughput and demonstrated a lower total installed cost – with no additional investment required by the customer.

TackSert®

Increased power output.

Switching from a thread forming screw to a TackSert® fastening solution allowed this customer to increase the output of their electric power pack system without increasing product dimensions – all while reducing installation time by 50%.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us:

1-800-342-5736