Why microPEM®

Product teardowns identified the need for assembly solutions that not only fit into compact spaces but also could be used with thinner/lighter materials

micropem® tackpin®

What are your costs to design a screw?

- Cost of screw

- Cost of patch to prevent loosening

- Cost of threaded insert or tapped hole

- Cost of installation time - screw vs press

- Cost of rework due to cross-threading

- Cost of driver bits

- Cost of rework due to driver bit “cam-out”

- Is this less than $7k-12k?

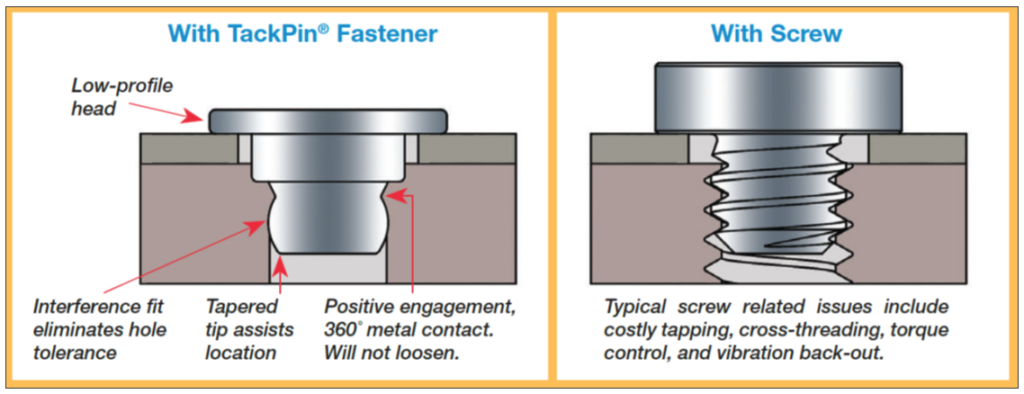

TackPin® vs Screw

TackPin®

- Low-profile head

- Interference fit eliminates hole tolerance

- Tapered tip assists location

- Positive engagement, 360 degree metal contact that will not loosen

- Less weight

Screw

- Costly tapping

- Cross-threading

- Torque control

- Vibration back-out

Leather Cell Phone Case

No space is available for loose screws so a T4 TackPin® was used.

Highly cosmetic finish on the anodized aluminum buttons protected by coordinating both the fastener design and the install process.

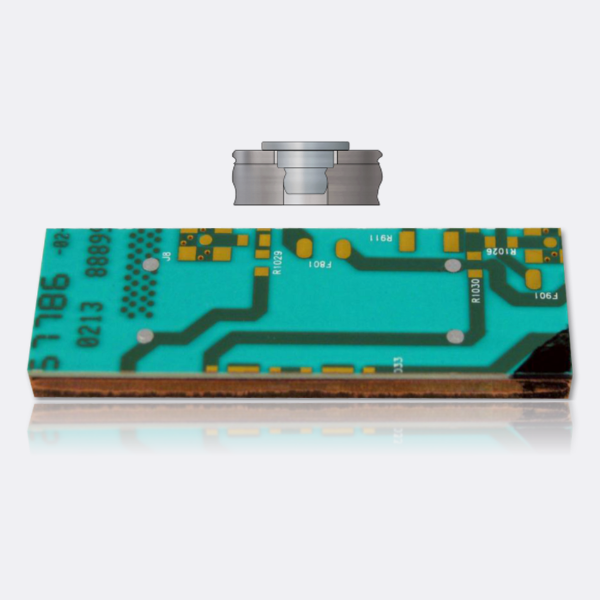

PCB to Copper Busbar

TackPin® replaced adhesive.

TackSert® Pins

- Cost-saving, Permanent, and Tamper-evident Screw Replacement

- Suitable for installation into plastics, metal castings and other brittle materials

- Reduce installation time vs a screw

- Simple press installation, does not require heat or ultrasonics

- Low profile head provides space savings

- Tapered tip aligns fastener in hole

Consumer Electronics

Credit Card Reader

This customer was looking to streamline their card-reader dongle. Their new reader is 50% thinner than their original reader. One of the ways they were able to accomplish this was by eliminating two screws. This plastic reader is never repaired; it is simply replaced. Therefore, there is no need for a removable screw, and now their product is thinner, and easier to assemble.

Other microPEM® Fasteners

MPP™ microPEM® Pin

- Satisfies micro positioning and alignment requirements with pin diameters as small as .40” / 1.0mm

- Flush installation into materials as thin as .020” / 0.5mm and as hard as HRB 92 / HB 195 such as stainless steel

- Made from A286 excellent corrosion resistance

- Chamfered end eases mating hole alignment

- RoHS compliant

MSO4™ microPEM® Standoff

- Thread sizes from M0.8

- Made from heat-treated 400 Series Stainless Steel. Stronger threads than weld standoffs

- Installs into materials with a maximum hardness of HRB 88 and as thin as 0.3mm / .012”

- Lengths as short as 0.7mm or .028”

- Round, knurled head for close centerline to edge placement

microPEM® MSOFS™ Standoff

- microPEM® MSOFS™ flaring standoffs attach permanently in panels as thin as .008” / 0.2mm of any hardness, including stainless steel

- Can be installed into any type of panel, including metal, plastic and P.C. Board

- Flaring feature allows for installation into multiple panels

- Small footprint allows for reduced centerline-to-edge designs

- Threads as small as M0.8

microPEM® SMTSO™ Standoffs

- Thread sizes from M0.8

- Steel and Brass material choices

- Electro-Plated Tin

- Sold on Tape-And-Reel or loose

- Hex body for additional strength

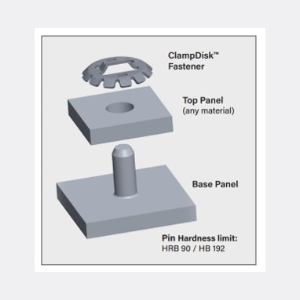

microPEM® ClampDisk® Fastener

- Clamp load generation

- Simple installation

- Removability

- Works with multiple panels of any material

- Limited installation stress to assemble

- Tamper-evident

microPEM® MSIB/MSIS/MSIA

- Thread sizes from M0.8

- Brass, Stainless Steel, Aluminum material choices

- Ultrasonic or Heat-stake installation

agsg