Products | Threaded Inserts

Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

Threaded inserts (also known as nut inserts or threaded bushings) fall into a class of their own thanks to the versatility of their application in plastics. In general, inserts for plastic implement a variety of features to create an interference fit, with knurls to resist rotation and barbs or undercuts to resist pullout. A flanged head can be applied to serve as an electrical contact point or to improve pull-through strength, while a symmetrical design lends well to automated mass-production. Specific combinations of profile features are favorable with different installation methods, which are determined by the makeup of the plastic into which the insert is installed. Brass is most often used due to its low cost, high conductivity and machinability, solidifying it as the industry standard. Aluminum is lead free and employed in low-weight applications while stainless steel is useful in corrosive or higher-temperature environments.

Installation

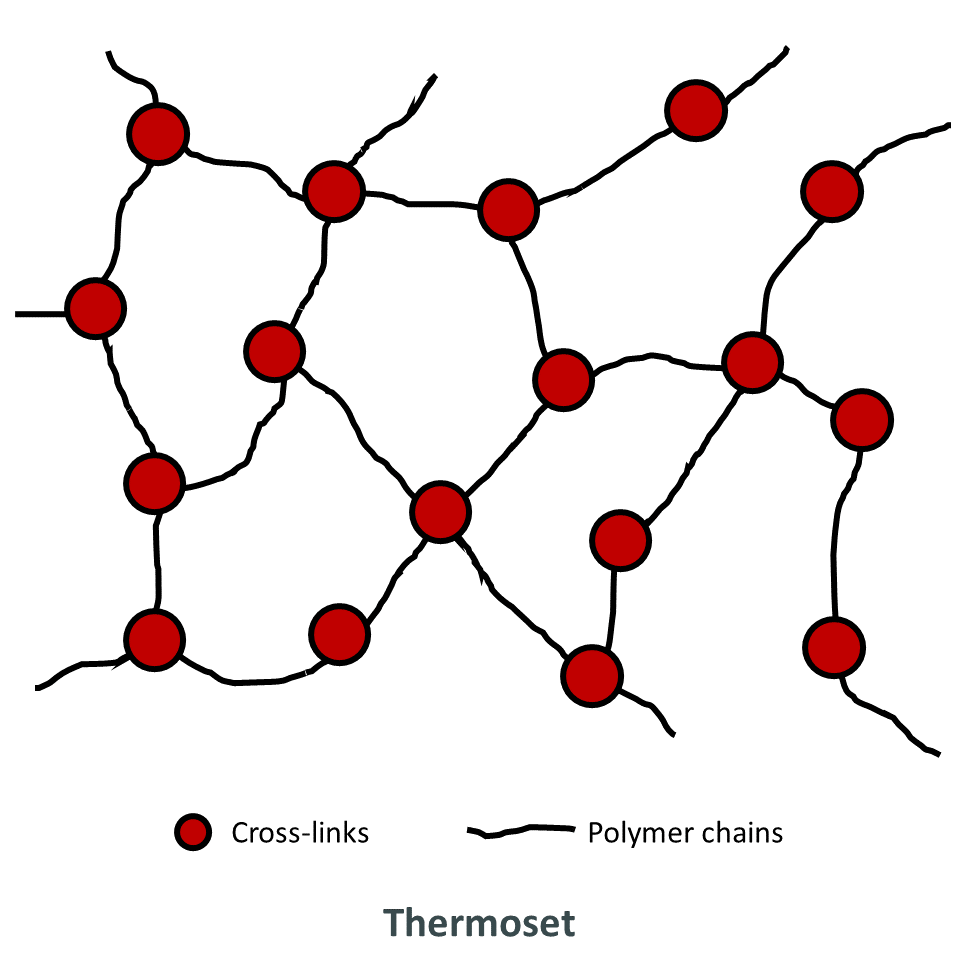

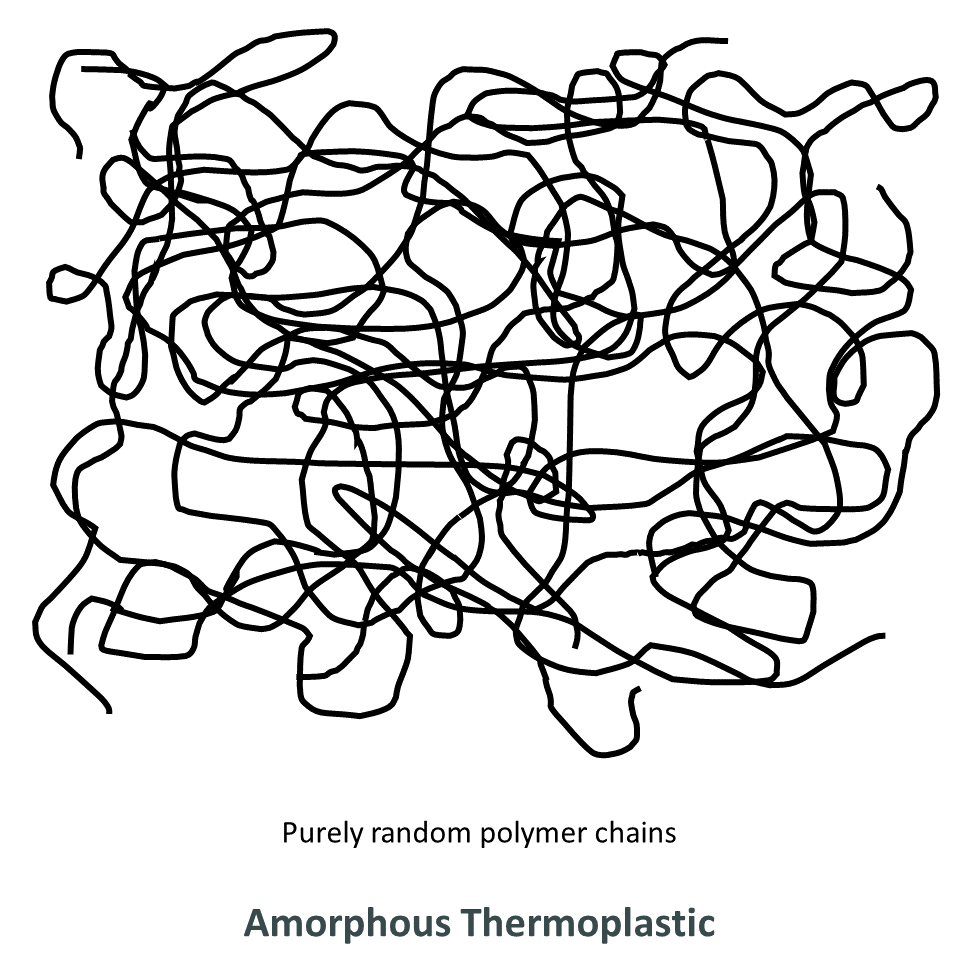

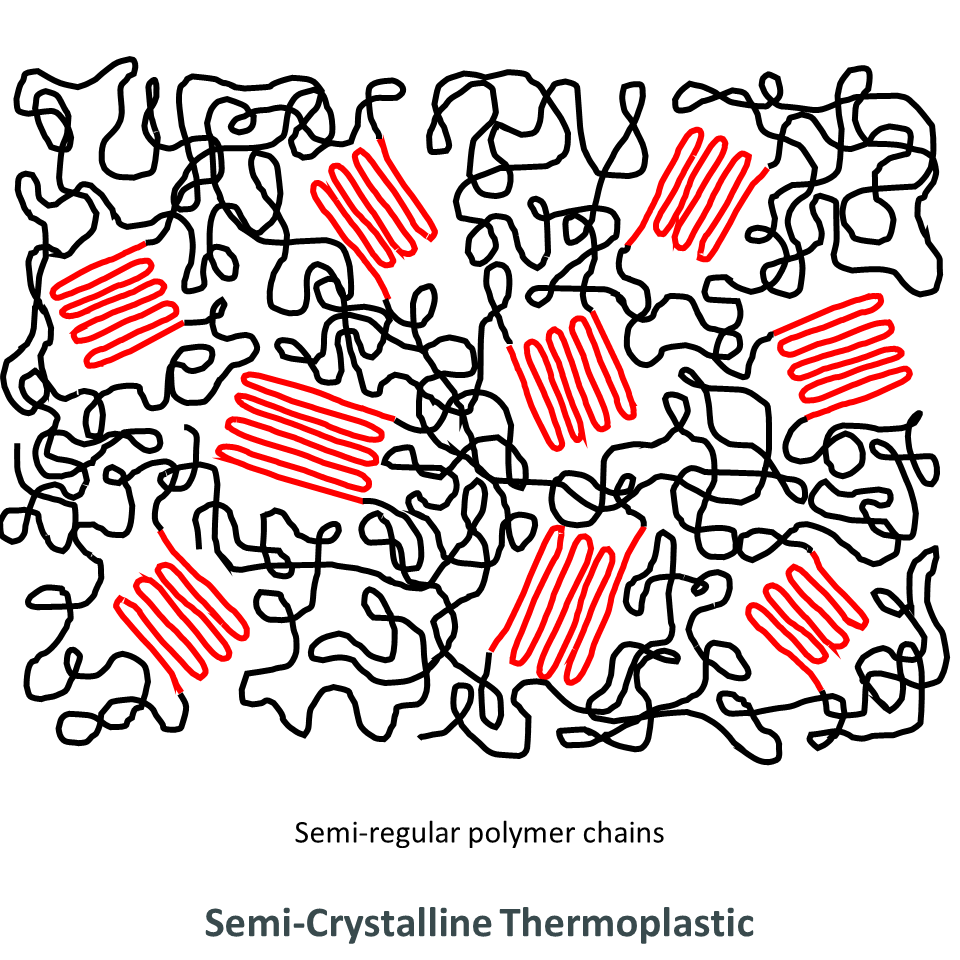

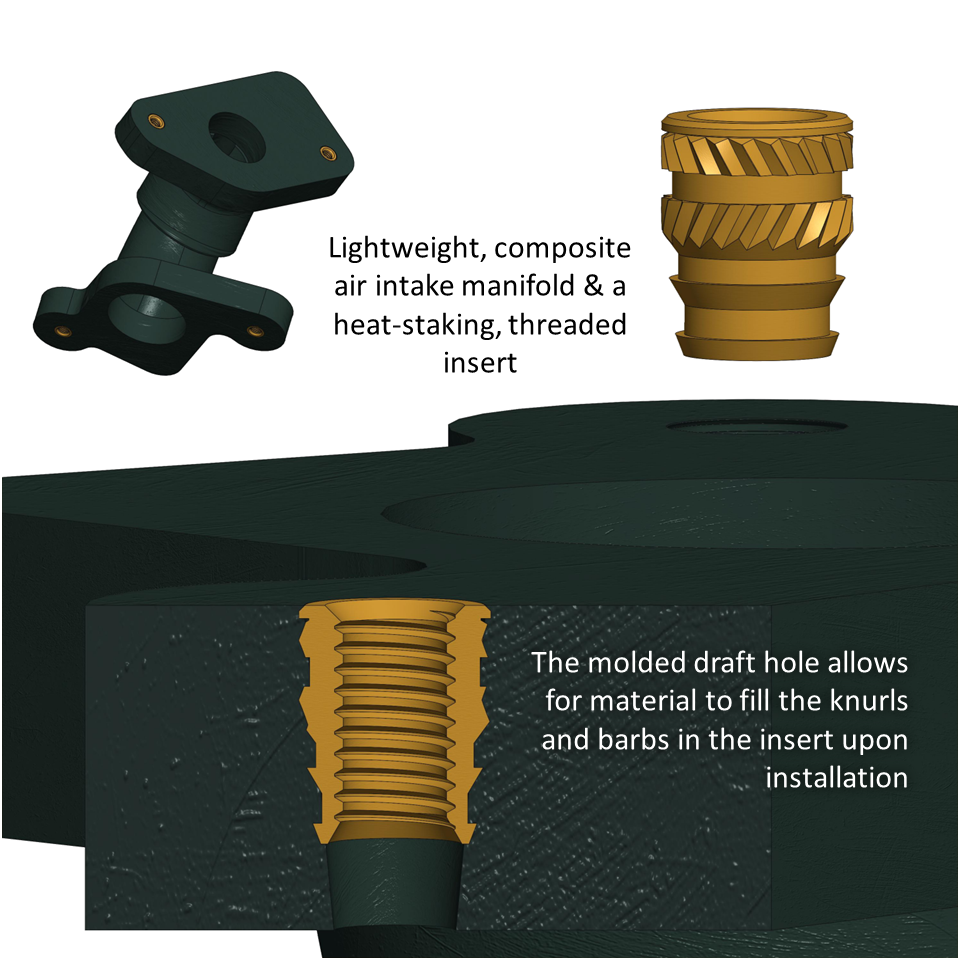

Plastic resins come in hundreds if not thousands of blends to achieve properties specific to a given application and are generally categorized as thermosets or thermoplastics. Thermosets, like epoxies, undergo a permanent transformation upon solidification, after which they burn rather than melt. To put metal threads in a thermoset, the best option is to use a molded-in insert (often a blind insert), with press-in inserts being a viable but lower-performance alternative. Thermoplastics can be re-melted or softened upon heating, allowing for post-mold installation of heat staking or ultrasonic inserts. Semi-crystalline thermoplastics like PET or PEEK have a well-defined melting point. Amorphous thermoplastics like ABS and PVC don’t have a consistent melting temperature, but rather go through a glass transition where the material becomes softer with increasing heat. These properties are important to note given that heat staking inserts must be heated with an installation machine to 50°F (28°C) above the melting temperature of the resin of the mating part.

Application

Any part or product that has a plastic housing almost certainly has threaded inserts so it can be assembled with metal screws. Composite plastics have seen increased use in the manufacturing of air intake manifolds in the automotive industry, their flexibility making them desirable over their metal predecessors. Holes or bosses molded into the glass-filled plastic can accept heat-staking inserts which locally melt the part to conform it to the knurls and barbs of the insert. These threads can securely mount the manifold to the engine with enough pressure to seal and properly deliver air to the cylinders.

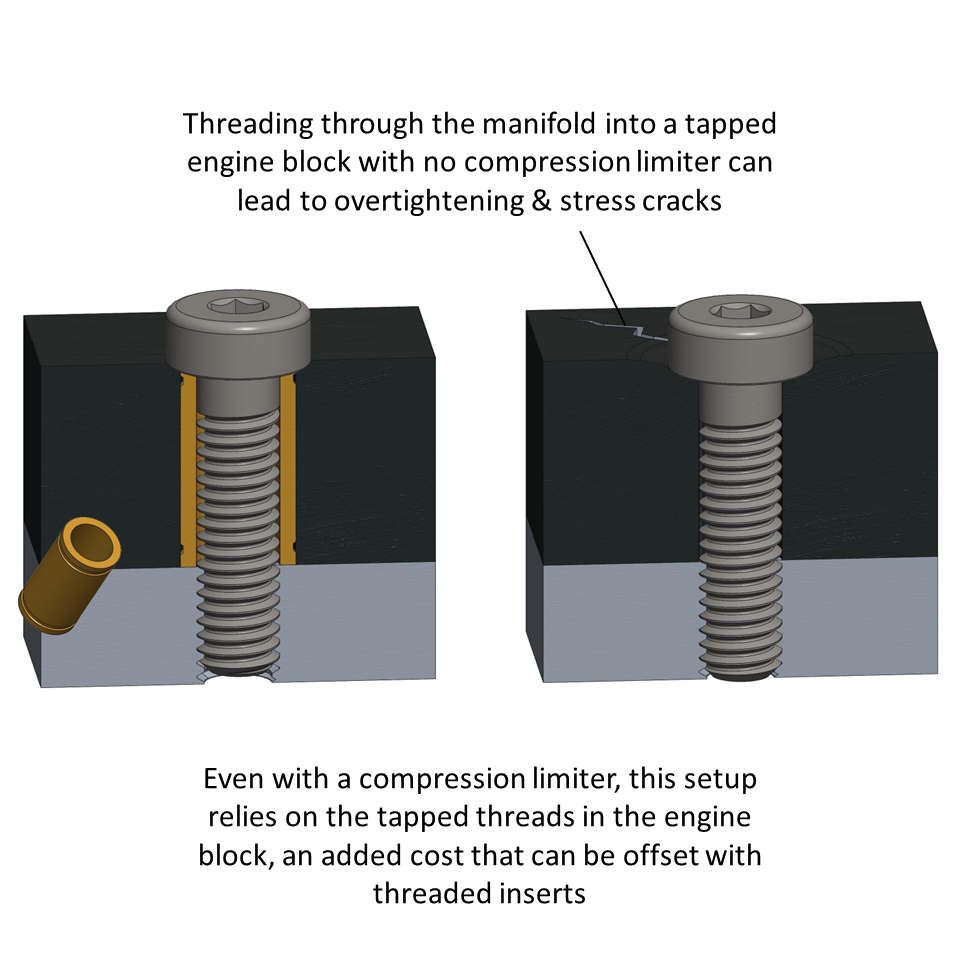

Threaded inserts can simplify production processes & mitigate damage risks due to stress.

Alternative Solutions

At the fastener level, Inserts can be swapped for a bolt and a washer threaded into the metal mating part of the joint, but without a compression limiter this joint has a risk of being overtightened. This excess stress can cause cracking and leaks in a plastic manifold, while the increased number of parts may be more expensive or heavier. When inserts are involved, the hole of the mating part is typically designed to rest on the face of the insert to avoid jacking it out of the plastic part. While a directly tapped, metal manifold might be more reliable long-term, the increased weight and cost of materials makes them less desirable.

Relevant Products from PEM:

Explore all the feature options of the SI® family in our Product Finder:

To learn more about our threaded inserts, visit the SI® Catalog.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736