Automotive Electronics

Stronger. Cleaner. More Reliable

Go above and beyond the ability of traditional screws – and see what’s possible with PEM® fasteners for automotive electronics applications.

Traditional weld nuts (caged or anchor), self tapping screws for metal, and sheet metal screws can be expensive options when considering total installed cost. And they can lengthen your time to market from secondary operations and inefficient installation time.

Choose PEM® clinch nuts, heavy-duty studs, surface mount technology, micro fasteners, and SI® threaded inserts for your automotive electronics applications – and move forward with cost savings, reliability, and eco-friendly performance.

automotive electronics

By the Numbers

90%

World's top automakers rely on PEM®

90% of the world's top automakers rely on PEM® fastening solutions.

1 million

Unique users

Nearly 1 million unique users research PEM® products per year.

20,000

Unique PEM® part numbers

Nearly 20,000 unique PEM® part numbers produced annually.

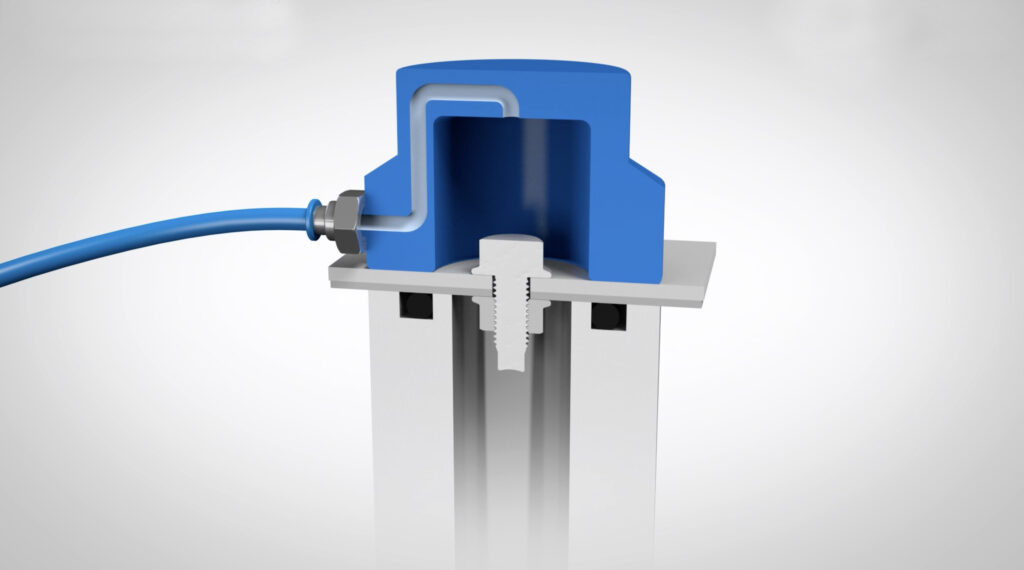

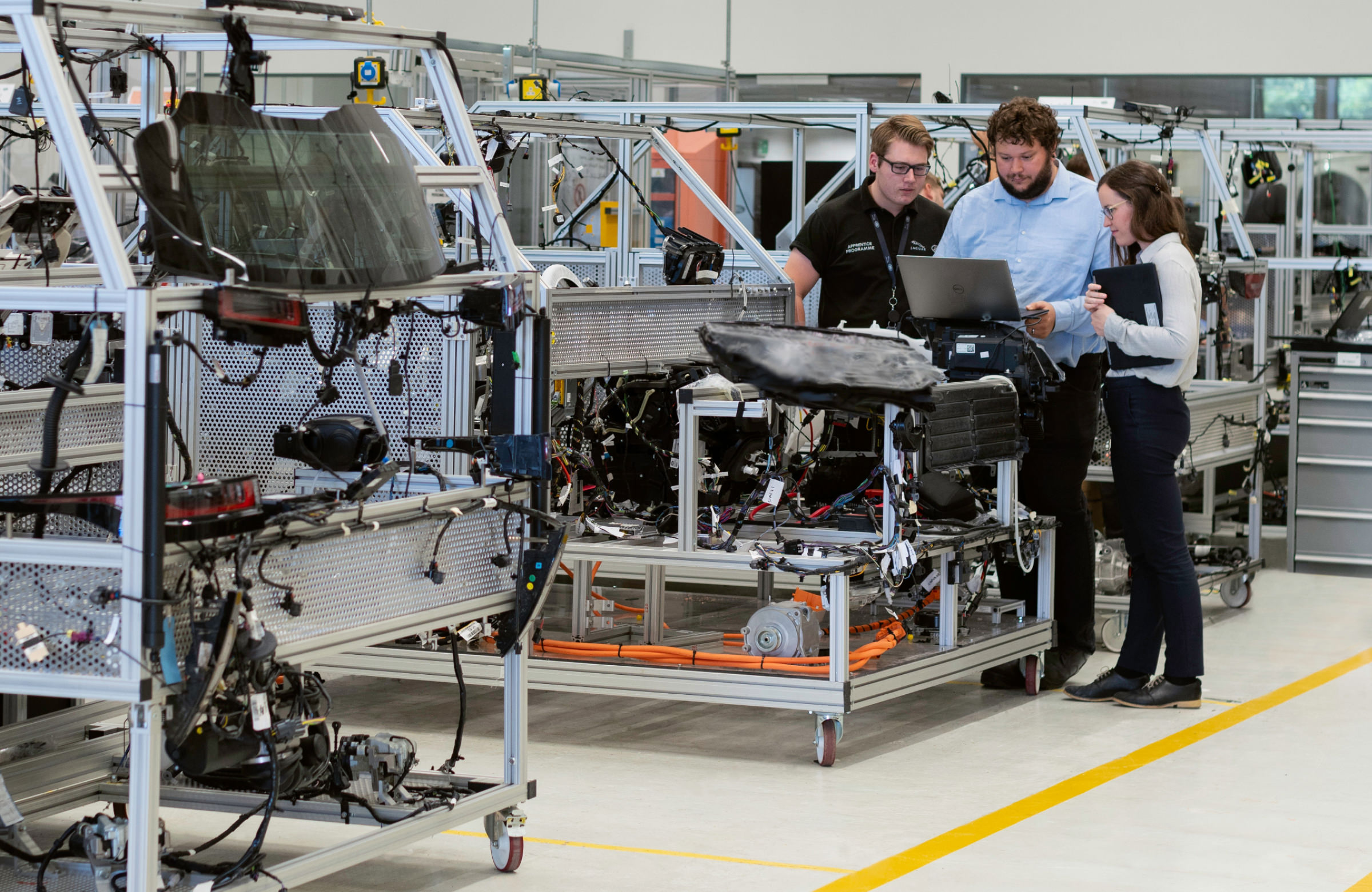

PEM® + Haeger®. A Total System Solution.

Using PEM® parts with Haeger® installation machines provides a total system solution – engineered to work together for greater efficiency and cost savings.

help center

Have a project? Let us help.

Have an application question? Talk to a PEM® engineer. Our engineers are fastener experts who can help you find the most reliable, cost-effective fastener solution for whatever challenge you’re facing.

We’ll send you fasteners to sample and use in your prototype. You can see firsthand how our solutions can help save you time, money, and resources.

Gain valuable insights from our extensive resources center. Includes product catalogs, CAD drawings, data sheets, videos, design guides, and more.

Find information on environmental and government compliance, quality approvals and certifications, and browse other regulatory resources.

Related Solutions

The Power to Connect

See how PEM® delivers engineering innovation with global services and capabilities that expand beyond the automotive electronics market.

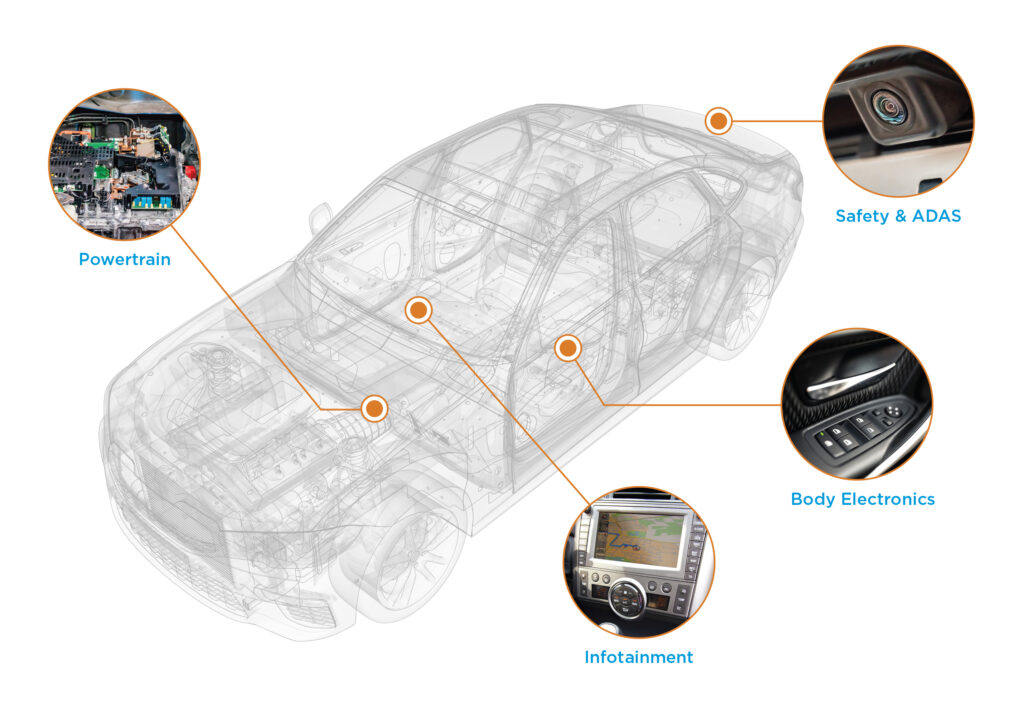

EV and Charging

The future is electric – and the engineering excellence behind PEM® fastening solutions is why many of the world’s top brands turn to PEM® as they face new challenges in an increasingly electric world.

Proven Performance for EV Battery Trays

PROFIL® Rivet Nuts RND

PROFIL® Self-Pierce Rivet Studs SBF

PEM® HFE/HFH Heavy Duty Studs

ATLAS® Blind Rivet Nuts

SI® Inserts for Plastics

Automotive electronics

Case Study

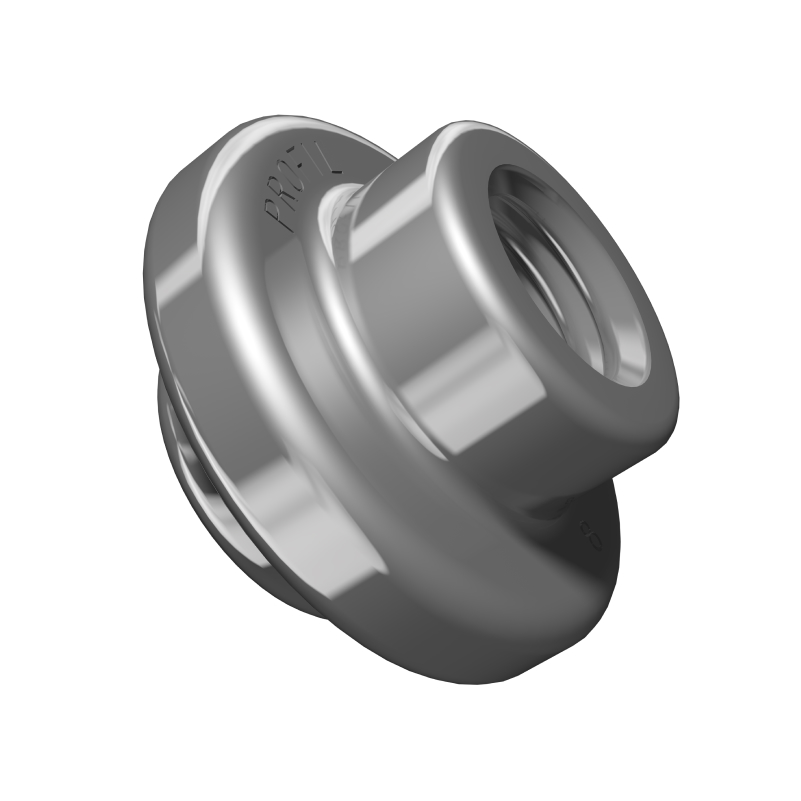

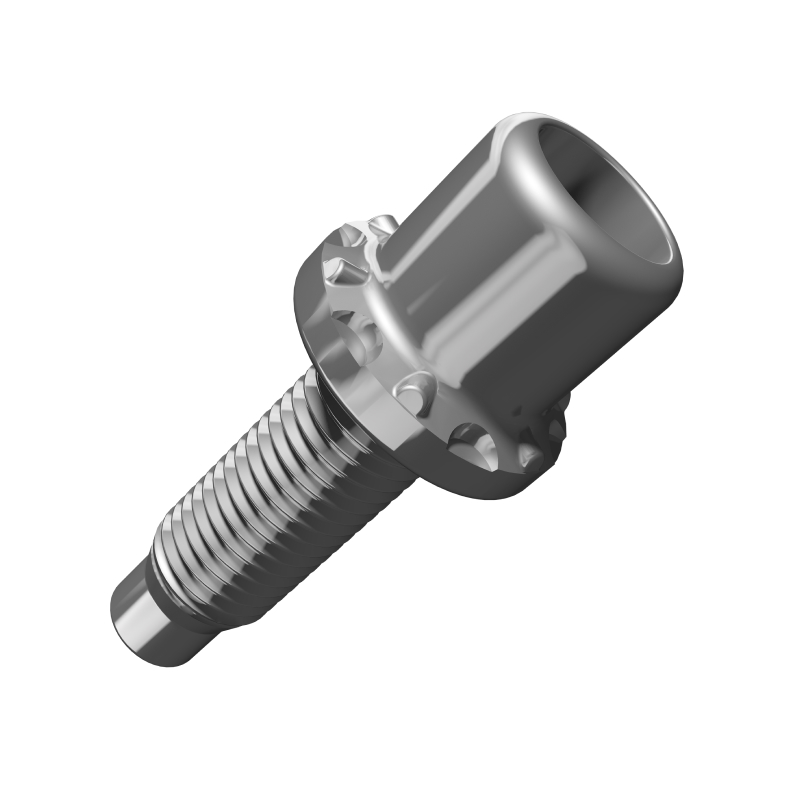

THFE® Heavy-Duty Studs

Critical safety achieved.

Switching to THFE® Heavy-Duty Studs simplified the assembly process for battery terminal connectors and satisfied the customer’s critical safety requirements for this high-voltage application.

PEMEDGE® Services

Gain a market edge.

Benefit from the expertise of trained engineers with this array of complimentary services. Designed to help improve your product’s cost, quality, time to market, and overall performance, these services advance your products and our world.

APPLICATION ENGINEERING

- Application Review

- Custom Design/Product Development

- Customer Drawings

- Catalog Samples

- 3D Models

- Prototype Development Center

Testing Service

- FEA Analysis

- Mechanical Testing

- Tensile and Compression Strength

- Micro Hardness

- Fastener Joint Cross-Sectioning

- Corrosion and Plating Testing

Teardown Service

- Complete Product Disassembly

- Assembly Structure Assessment

- Identify Alternative Fastening Solutions

- Alternative Fastener Replacement/Testing

- Teardown Report

- Identify Efficiencies/Implementation Plan

FASTENERCLASS® MASTER CLASS

- Free Customized Training Sessions

- Learn from Global Experts

- Live, web-based, and pre-recorded training options available

Standard Classes Include:

- Theory, Best Practices, Application Exploration

- Intro to Self-Clinch Theory

- Proper Fasteners for Stainless Steel Panels

- Surface Mount Fastener Technology (SMT) vs. Broach

Virtual Tech Support

- Connect with a live senior PEM® Engineering expert – you choose the date/time

- Get advanced consult for your application and design questions

- Review drawings and 3D models

- Discuss technical cleanliness needs

- Explore product teardown opportunities

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Email us at: [email protected]

Or call any of the direct phone numbers listed below:

Europe: 353-91-751714

U.S.: 1-866-236-4063

China: 86-21-5868-3688

Singapore: 65-6-745-0660