Self Clinching Nut vs Weld Nut

Discover the advantage of clinch nuts and other PEM® self-clinching fasteners. A strong and versatile alternative to weld nuts and challenging spot weld and tack weld processes.

Weld vs. Self Clinch Comparison Chart

Compare Self Clinching Nuts to Weld Nuts

See why innovative self clinching fasteners (commonly referred to as clinch nuts or press nuts) are the smart alternative to conventional tack weld fasteners. Achieve greater versatility, durability, performance, and cost savings – with installation methods that are cleaner and safer for the environment.

| Benefit | Self Clinching Nuts | Weld |

| Cost-Saving In-Die Installation | Single-step in-die installation capability eliminates secondary operations, increases throughput, cuts costs | Secondary tack weld operations require more manufacturing time and energy consumption |

| Fasten Dissimilar Materials | Able to be fastened into several materials like common steel, HSS, sandwich panels, hot forming steel, and aluminum. | Welding can only be performed on similar materials |

| Stronger Joints | The lack of a heat source (required for weld nuts) produces no weak points due to thermal effect | The welding process increases the chance for thermal stress or annealing |

| Reduced Weight | A mechanically attached nut is typically lighter than a weld nut while maintaining similar performance | The welding process adds additional weight to the part |

| No Coating or KTL Effect | Can install a coated fastener into a panel without disturbing the coating or KTL of either part | Welding process burns off existing coatings and creates opportunity for corrosion |

| Full-Service Technical Support | PennEngineering® provides comprehensive support – applications engineering, tooling, manufacturing, training, and tech support | Weld fastener manufacturers typically do not provide design and technical support |

Self clinching fasteners are strong, versatile and design-engineered for a broad range of fastening applications – a smart alternative to conventional spot weld fasteners.

Self clinching is the idea that revolutionized production fastening and put PennEngineering® on the map as a global industry leader. As demand for holding together thinner and lighter metals grew, so did the line of innovative products.

Our original self clinch design has evolved to meet hundreds of new applications across many industries. Self clinching nuts (commonly referred to as clinch nuts or press nuts), studs, spacers, standoffs, access hardware, and other components are used worldwide in automotive, consumer electronics, datacom/telecom, industrial, and others.

Discover the advantages of PEM® self clinching fasteners.

- Strong threads/attachment in metal as thin as 0.20 mm / .008″

- Installs into a plain, round hole

- Installed using any parallel acting squeezing force

- High pushout and torque-out resistance

- Requires no special hole preparation

- Reverse side of metal sheet remains flush

- No retapping necessary after application

- Low total installed cost

- In-die installation for high volume applications

why self clinch?

Why Choose Self Clinching Fasteners?

Clean Process

Self clinching fasteners are cleaner and more environmentally friendly than weld – with no weld splatter and less energy consumption.

In-Process Installation

Self clinching fasteners are easily and efficiently installed into a plain round hole, with no secondary operations needed.

Design Flexibility

Able to be fastened into dissimilar materials – common steel, HSS, and many others.

Cost Reduction

Achieve decreased installation cycle times for both medium-volume and high-volume applications. In-die capability available.

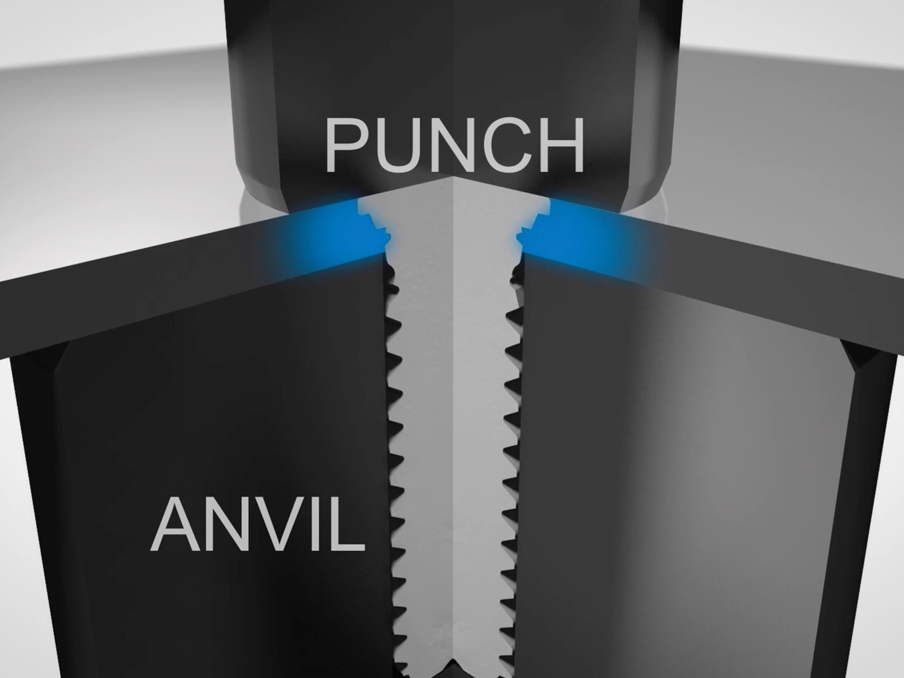

self clinch installation

Self Clinching in Action

Featured and Related Resources

Installing Self Clinching Fasteners

Whether you have a medium-volume or high-volume application, there are cost-effective and energy-saving solutions available for self clinching fastener installation. Learn more about Haeger® robotic/manual installation and PEMSERTER® in-die installation.

Issues with Welding

The Challenges with Weld

- Time-consuming and labor-intensive process

- Increased energy consumption from secondary operations

- Weakened joint strength from spot weld heat

- Cannot weld dissimilar materials

- Process can add additional weight to product

- Difficult to achieve water-tight seals on weld nuts

- Welding process requires technical skillset

- Opportunities for corrosion from coatings burning off

PEM® Self Clinching Stud vs. Weld Fastener

- Reduced energy consumption of installation system

- Reduced logistics costs

- Increased thread strength

- No thread contamination

- No introduction of thermal stresses

- Reduced environmental concerns

- Fastener rationalization

- Panel and/or fastener can be pre-finished

Application Examples

Converting from Weld Nuts to Self Clinching Nuts

Consumer Electronics

Application

Mobile Phone

PEM® Solution

MSO4™ Standoffs

Following the switch from weld fasteners to MSO4™ standoffs, this next-gen phone used a lighter 0.3mm aluminum chassis as they no longer needed to use similar materials for welding.

Datacom/Telecom

Application

Network Storage Chassis

PEM® Solution

SO™ Standoffs

The customer previously used weld standoffs but experienced challenging weld marks on the customer-facing side of the product. Switching to a self clinching standoff eliminated the issue and improved cosmetics.

Industrial

Application

Heat Exchanger

PEM® Solution

Multiple FH4™ Studs

Over two million weld studs per year were replaced with FH4™ studs in M4, M5 and M6 sizes.

Medical

Application

X-Ray Image Processor

PEM® Solution

SFP™ SpotFast® Fasteners

This customer was already using other PEM® fasteners in this application. They learned they could eliminate costly weld splatter repairs by switching from spot-welding to self clinching with the SFP™ SpotFast® fastener.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736