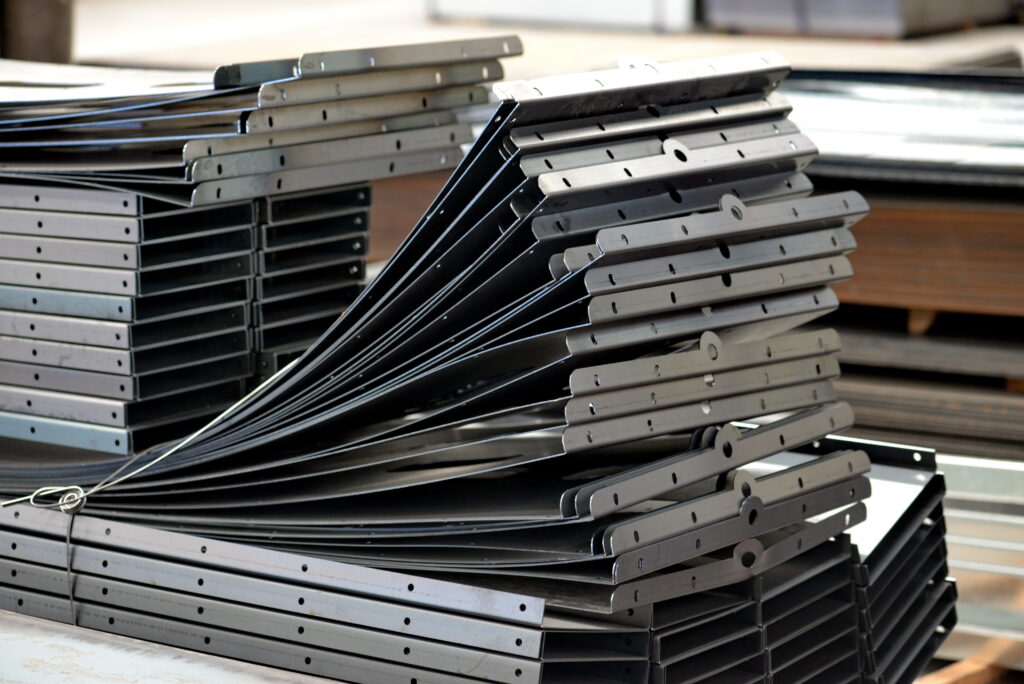

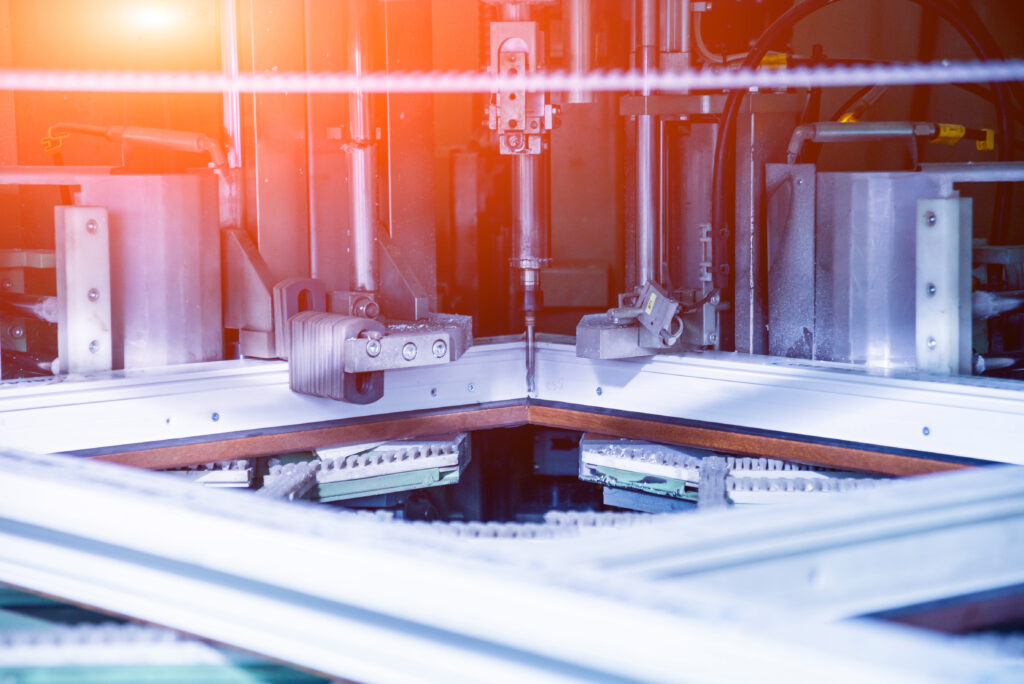

Sheet Metal and Metal Enclosures

We think outside the box for what goes inside the box.

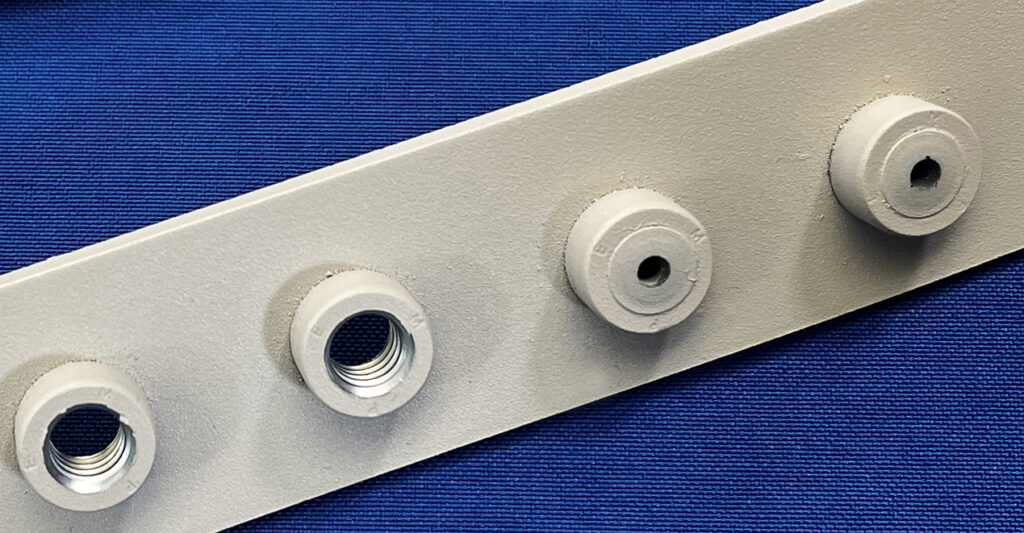

PEM® provides precise and consistent mechanical joint attachments for metal enclosures and sheet metal applications. Compared to traditional methods such as spot welding, stud welding, and screwing, benefits of self-clinching fasteners include low production costs, limited prep work and the ability to attach dissimilar materials. We are the environmentally friendly option that is easier to reproduce and more durable than alternatives.

Learn more about self-clinching technology and check out our comparison chart for more.

Whether it’s simplifying an assembly by reducing loose hardware or creating a more appealing aesthetic for a product, trust the innovation behind PEM® clinch attach hardware for your most challenging sheet metal and metal enclosure applications.

Generator and motor housings

Farm and tractor sheet metal

Motorcycle sheet metal

Electrical cabinets

Marine and outboard motors

Appliance fabrication: ranges, refrigerators, dishwashers, freezers and commercial kitchen

Innovations Lab. Where Anything is Possible.

See what’s possible in the PEM® Innovations Lab. Here, collaboration between customers and PEM® applications engineers drives new ideas and new product innovations to advance performance for even the most challenging applications.

help center

Have a project? Let us help.

Have an application question? Talk to a PEM® engineer. Our engineers are fastener experts who can help you find the most reliable, cost-effective fastener solution for whatever challenge you’re facing.

We’ll send you fasteners to sample and use in your prototype. You can see firsthand how our solutions can help save you time, money, and resources.

Gain valuable insights from our extensive resources center. Includes product catalogs, CAD drawings, data sheets, videos, engineering guides, and more.

Find information on environmental and government compliance, quality approvals and certifications, and browse other regulatory resources.

Related Solutions

The Power to Connect

See how PEM® delivers engineering innovation with global services and capabilities that expand beyond the industrial/commercial market.

Consumer Electronics

See what’s possible with PEM® fastening solutions for consumer electronics. From catalog to custom parts, PEM® fasteners use self-clinching, broaching, flaring, and surface-mount technology for strong, reusable, and permanent threads and mounting points in different ductile/non-ductile materials.

Thinner. Lighter. Stronger.

Wearables

Laptops

IOT

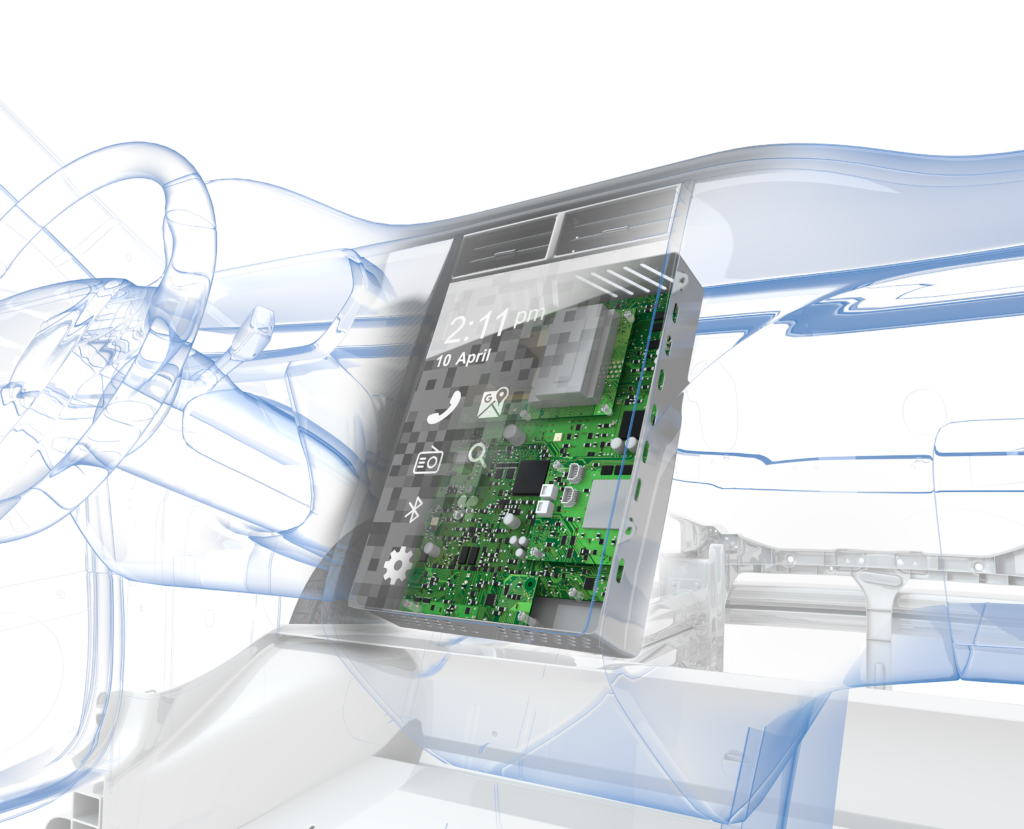

Automotive Electronics

microPEM® Concealed Rotary Standoff

New concealed rotary standoff technology from microPEM® allows fasteners to install into thin-sheet metal at low axial force – keeping one side of the panel aesthetically clean with minimal or no markings while providing strong pull-out and torque-out resistances.

- New and innovative standoff installation

- Clean, smooth aesthetic when installed into thin, cosmetic-faced panel

- Concealed head

- Can install into sheets as thin as 0.020” / 0.5mm

- Installation method allows for fastener to be made of most materials

PEMEDGE® Services

Gain a market edge.

Benefit from the expertise of trained engineers with this array of complimentary services. Designed to help improve your product’s cost, quality, time to market, and overall performance, these services advance your products and our world.

APPLICATION ENGINEERING

- Application Review

- Custom Design/Product Development

- Customer Drawings

- Catalog Samples

- 3D Models

- Prototype Development Center

Testing Service

- FEA Analysis

- Mechanical Testing

- Tensile and Compression Strength

- Micro Hardness

- Fastener Joint Cross-Sectioning

- Corrosion and Plating Testing

Teardown Service

- Complete Product Disassembly

- Assembly Structure Assessment

- Identify Alternative Fastening Solutions

- Alternative Fastener Replacement/Testing

- Teardown Report

- Identify Efficiencies/Implementation Plan

FASTENERCLASS® MASTER CLASS

- Free Customized Training Sessions

- Learn from Global Experts

- Live, web-based, and pre-recorded training options available

Standard Classes Include:

- Theory, Best Practices, Application Exploration

- Intro to Self-Clinch Theory

- Proper Fasteners for Stainless Steel Panels

- Surface Mount Fastener Technology (SMT) vs. Broach

Virtual Tech Support

- Connect with a live senior PEM® Engineering expert – you choose the date/time

- Get advanced consult for your application and design questions

- Review drawings and 3D models

- Discuss technical cleanliness needs

- Explore product teardown opportunities

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or call any of the direct phone numbers listed below:

U.S.: 1-866-236-4063

Europe: 353-91-747100

China: 86-21-5868-3688

Singapore: 65-6-745-0660