Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

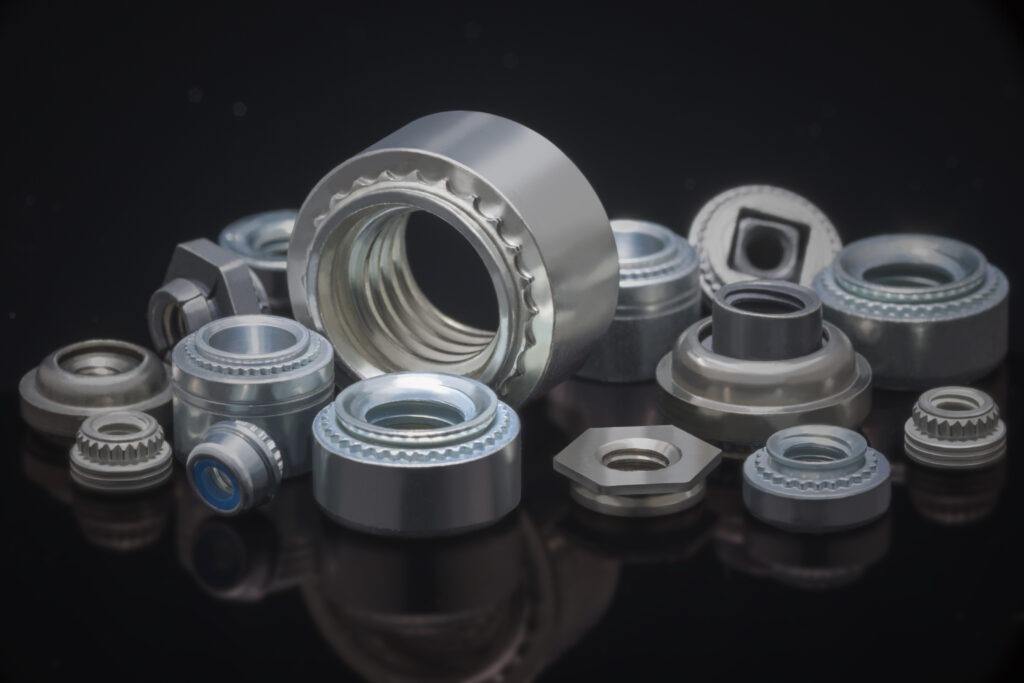

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

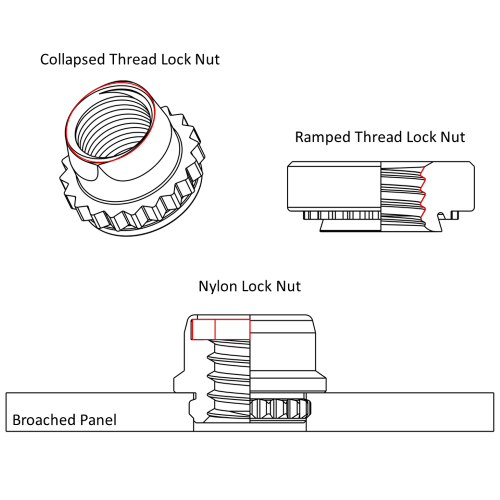

Locking Nuts

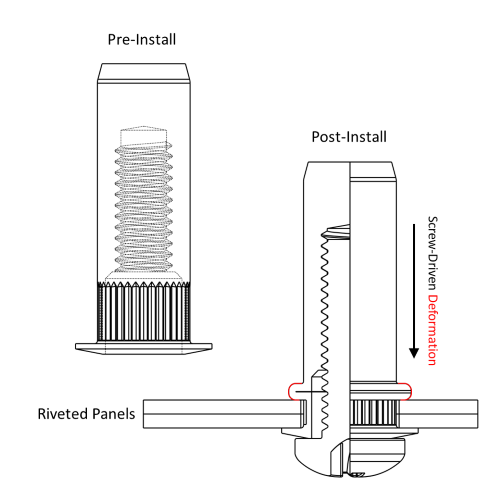

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

Threaded nuts can take on many different forms to solve a variety of application challenges, but the general concept is fairly simple. A nut is any single threaded part that can accept a male thread (a screw, bolt, or stud) and is used to join two components together via torque. The most common nut geometry is a hexagonal body with internal threads, the length of which is typically shorter than the outer diameter. The hex body can be leveraged to apply torque for tightening or loosening.

Application

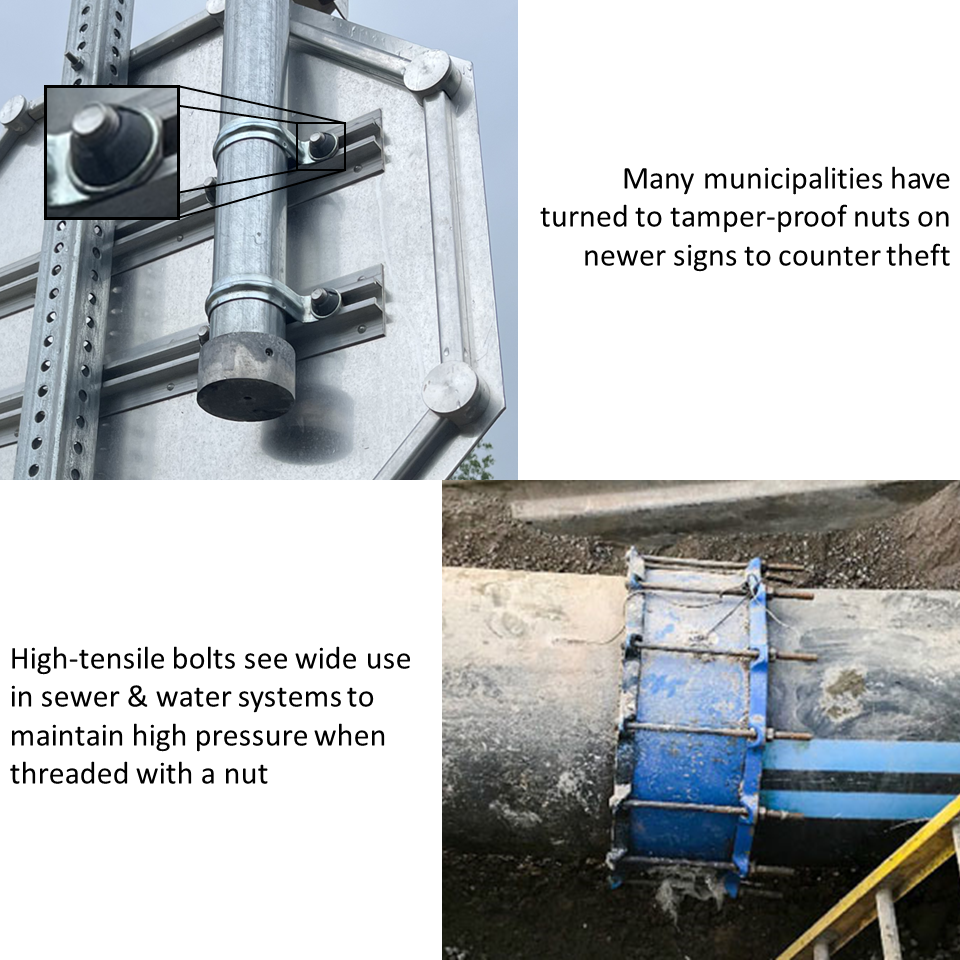

The general form of a nut is so widely applicable that it’s difficult to narrow the scope without discussing more unique variations such as floating nuts, blind nuts, or flush nuts. Common applications are as simple as fastening a stop sign to an aluminum post, or as critical as bolting two pipes together in a sewer system. The range of applications that use the general form of a threaded nut will typically result in different material decisions rather than design decisions, such as using high tensile strength bolts or lightweight, plastic nuts.

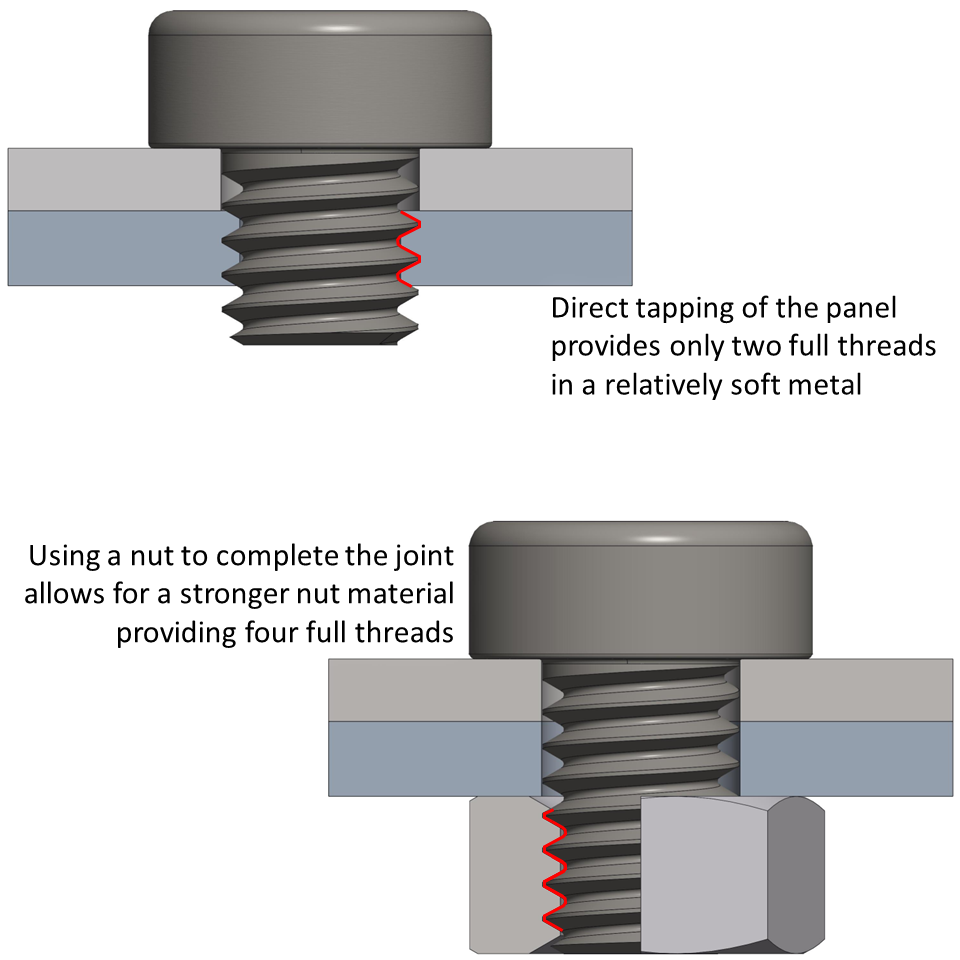

Nuts provide more freedom when designing a joint with stronger materials

available than the panels that are being joined.

Alternative Solutions

Common reasons for using loose nuts and bolts include the low cost per piece and easy assembly/disassembly. Many applications require only ‘finger-tight’ fastening, meaning no additional tools are required. If minimizing part count is beneficial to the application, the nut can be eliminated by tapping threads directly into the steel post or sewer pipe. However, this results in two disadvantages. Tapping the thin metal of an aluminum post creates softer and fewer threads, increasing the risk of failure. Additionally, much of the cost savings gained by eliminating the nut is lost from the labor required to tap the metal panel.

Common Attachment Technologies

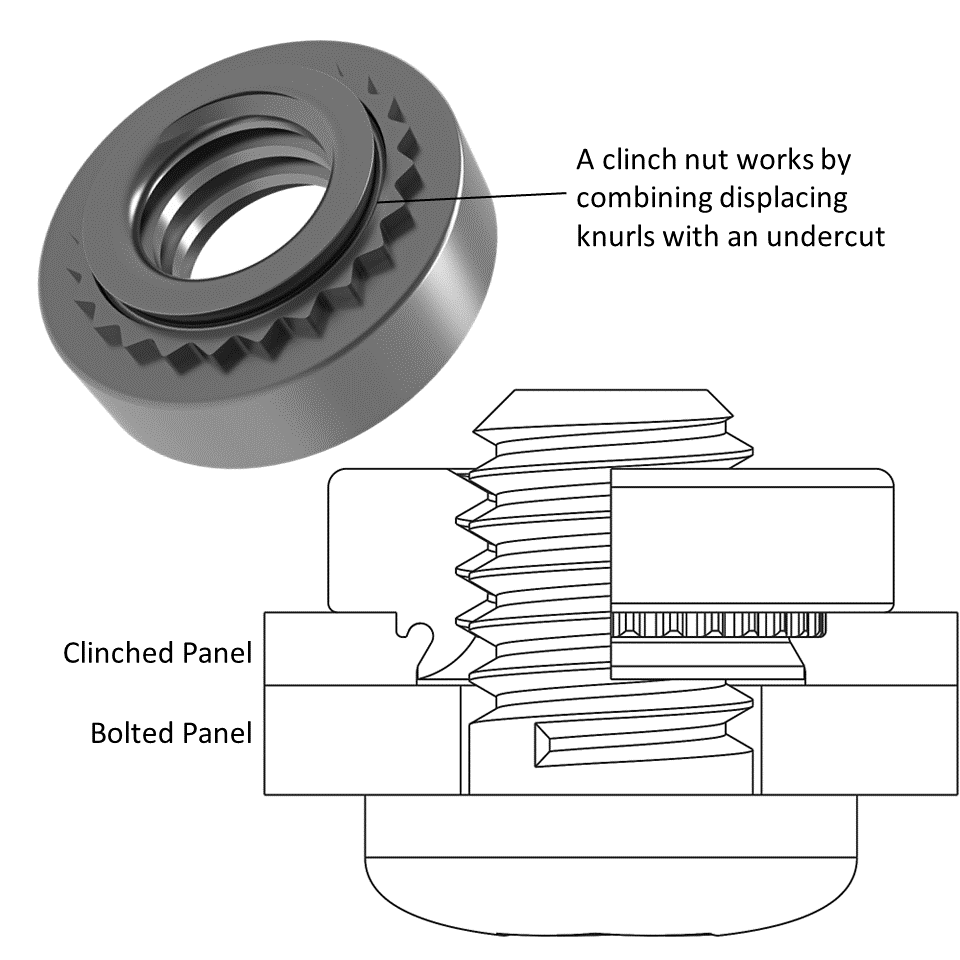

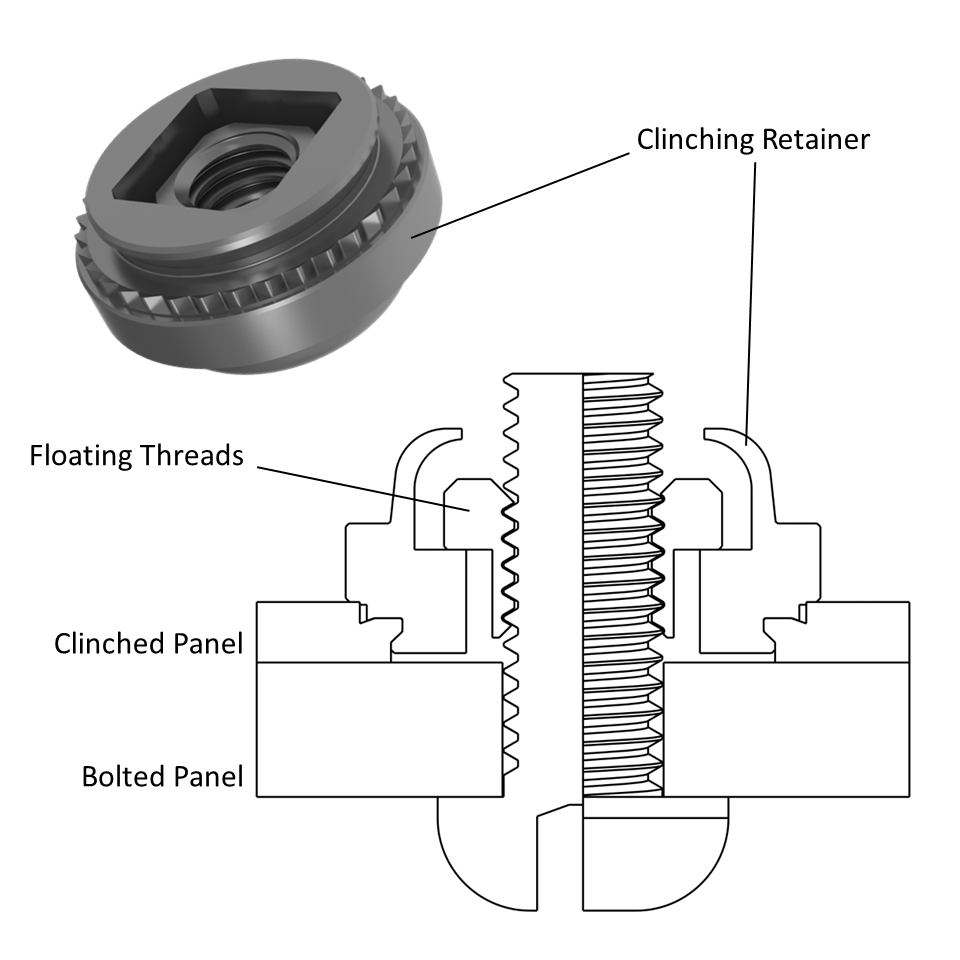

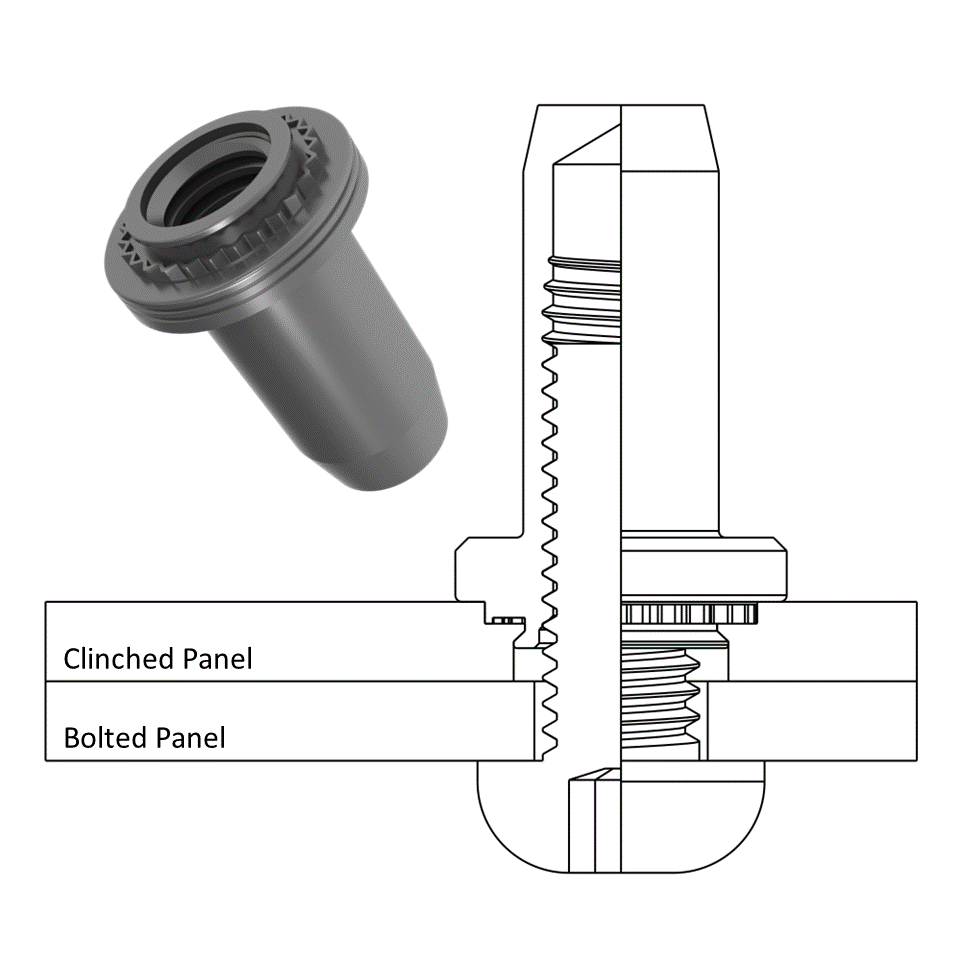

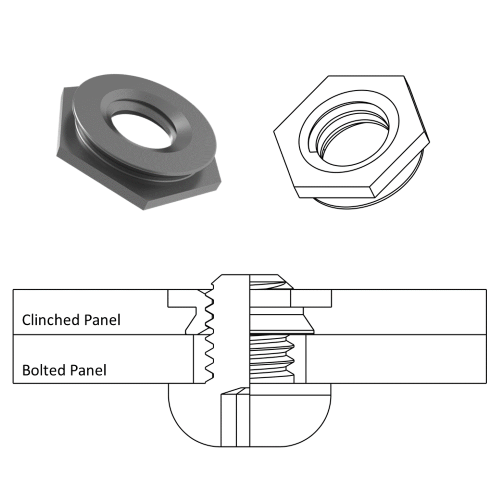

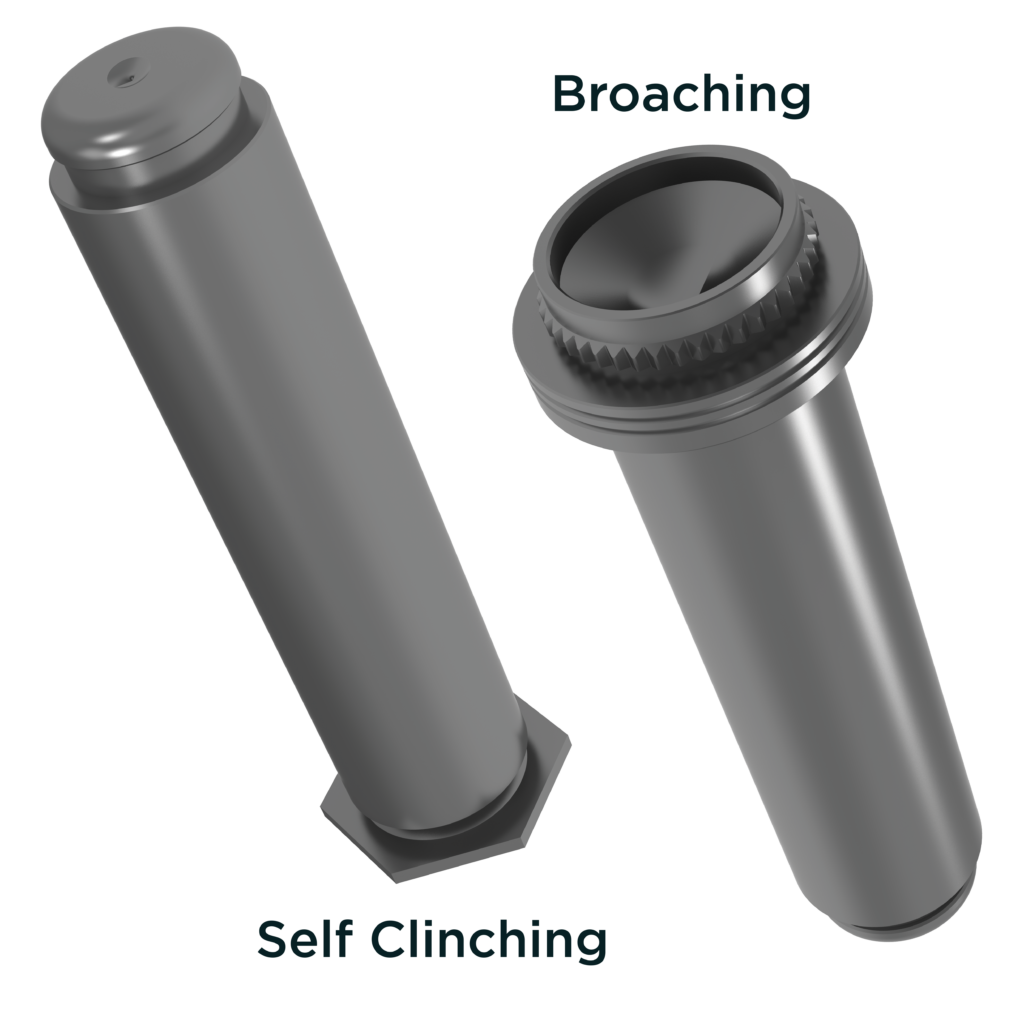

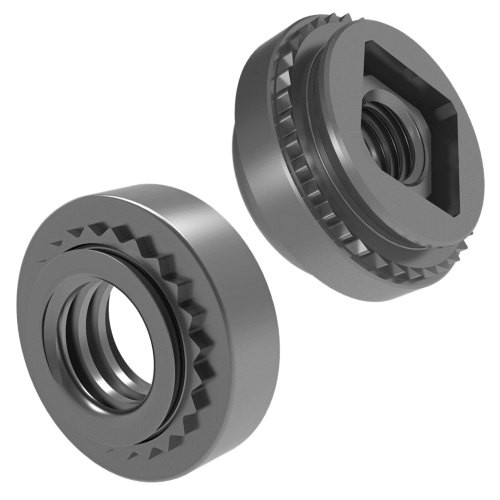

General threaded nuts are loose parts that mate with a male thread. But a wide range of specific applications see nearly every kind of attachment technology used to put threads on a metal panel or PCB. Self-clinching nuts are common enough to simply be called clinch nuts.

Relevant Products from PEM:

Explore nuts for manufacturing in our Product Finder:

To learn more about our extensive catalogue of threaded nuts, visit the following datasheets:

CL Datasheet - Standard profile, self-clinching nuts

ALA Datasheet - Self-clinching, floating nuts

B Datasheet - Self-clinching, blind nuts

F Datasheet - Self-clinching, flush nuts

LN Datasheet - Self-clinching, lock nuts

K Datasheet - SMT and broaching nuts

ATLAS® Catalog - Blind rivet nuts

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736