SI® Brand Compression Limiters

Compression limiters are non-threaded inserts that are commonly used in applications where a compressive load is applied to a plastic assembly.

Compression limiters are non-threaded inserts that are commonly used in applications where a compressive load is applied to a plastic assembly. The compression limiter strengthens the plastic and withstands the compressive force that is applied when a mating screw is tightened. The integrity of the plastic is not compromised by the load that is applied.

Custom designed in a wide range of sizes and profiles, features include:

- Available in brass, stainless steel, and lead-free aluminum

- Installed using ultrasonic, heat-staking, press-in or molded-in installation methods

- Available design types; flange-head, symmetrical, full diamond knurl and non-knurled symmetrical

Flange-Head

- Mold In

- Press In

- Ultrasonic/Thermal

Larger contact area provides high resistance to axial loads and eliminates direct contact of plastic with mating components. Can be used for all installation methods.

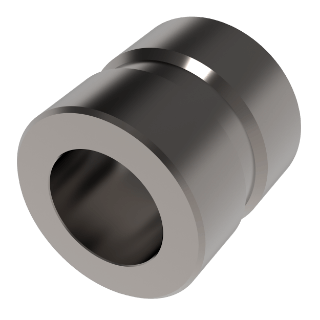

Symmetrical

- Mold In

- Press In

- Ultrasonic/Thermal

Symmetrical design offers fast loading without the need to orientate the part. Can be used for all installation methods.

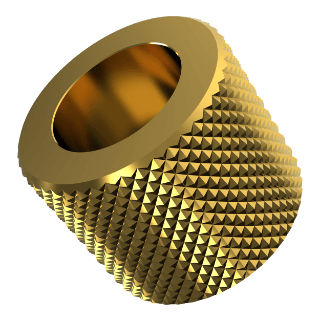

Full Diamond Knurl

- Mold In

Symmetrical design and uniform diamond knurl reduces the risk of sink marks. Can be used in mold-in installation.

Non-Knurled Symmetrical

- Mold In

Symmetrical design with retention groove for use in automation and high-volume applications needing compressive load resistance. Can be used in mold-in installation.

Installation Methods

Ultrasonic/Heat Staking

- Ultrasonic – Installed by pressing the insert into the mounting hole with ultrasonic insertion equipment while simultaneously applying a high frequency vibration. Frictional heat caused by the vibration melts the plastic surrounding the insert allowing easy insertion. When the vibration ceases, the plastic solidifies, locking the insert permanently in place.

- Heat Staking – Installed by pressing the insert into the mounting hole with a thermal press to melt the plastic surrounding the insert.

Molded-In

- Installed during the molding process, the inserts are located in the mold cavity by core pins. When the mold opens, the core pins are withdrawn leaving the inserts permanently encapsulated in the plastic section with only the threads exposed.

- Installing the inserts during the molding process eliminates the need for secondary steps or installation equipment.

Press-In

- Installed by cold pressing the insert into the mounting hole. The knurl cuts into the plastic and no melting occurs.

Knurling Overview

Knurling is used to add additional holding strength to the insert/compression limiter in the plastic component. Certain knurl patterns are more common and perform better for specific installation methods. Typically, compression limiters endure more compressive loads than rotational torque load. The types of knurls available for our compression limiters are noted below.

Non-Knurled

This is primarily used for mold-in applications where no rotational torque resistance is needed. An undercut is typically added to provide resistance to pull-out loads. No knurling is applied to the outside of the part.

Diamond Knurl

This pattern is primarily used & recommended for mold-in installation methods. It will provide added holding strength for torque and pull-out loads.

Diagonal Knurl

This pattern can be used for all methods of installation but is primarily more common for use with ultrasonic, thermal or press-in installation methods. It will provide added holding strength for torque and pull-out loads.

Straight Knurl

This pattern can be used for all methods of installation but is primarily more common for use with ultrasonic, thermal or press-in installation methods. It is very similar to a diagonal knurl but will not turn slightly during installation like the diagonal due to the straight knurl pattern. It will provide added holding strength for torque and pull-out loads.