Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

Standoffs are a versatile family of fasteners designed to hold a fixed gap between two panels via some static attachment. They are either cut from rigid bar stock in round or hex profiles based on the application requirements or formed from round wire. A standoff with a male attachment has external threads like a screw or bolt, while a female attachment has internal threads like a nut. Some SNAP-TOP® or KEYHOLE® standoffs can forego threads in order to solve specific application problems.

Application

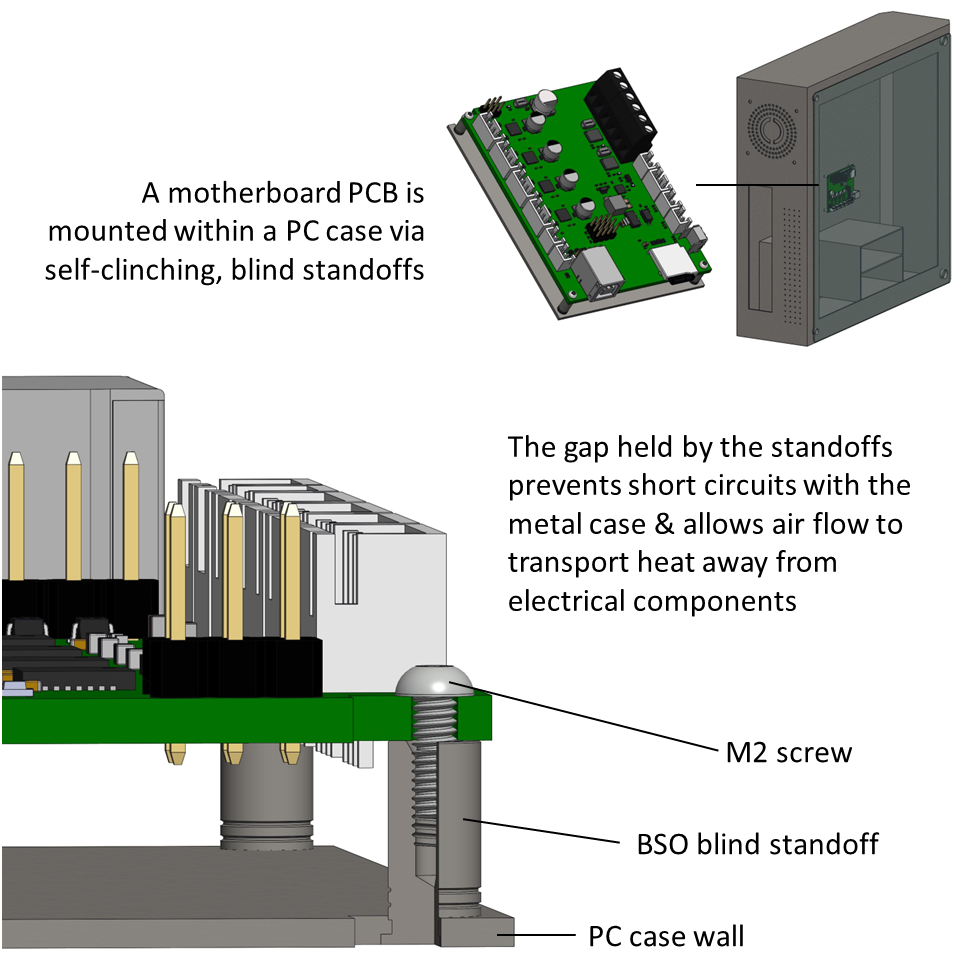

A common application for threaded standoffs is the mounting of PC Boards to manage potential short circuits. The housing of a gaming PC is essentially a large, current-carrying box of sheet metal; raising the motherboard away from the housing helps eliminate the risk of a short circuit between components. Blind standoffs in particular can provide threads without a through-hole compromising the internal components.

Electrical safety, temperature management & dimensional accuracy make a strong case for standoffs when mounting PCBs.

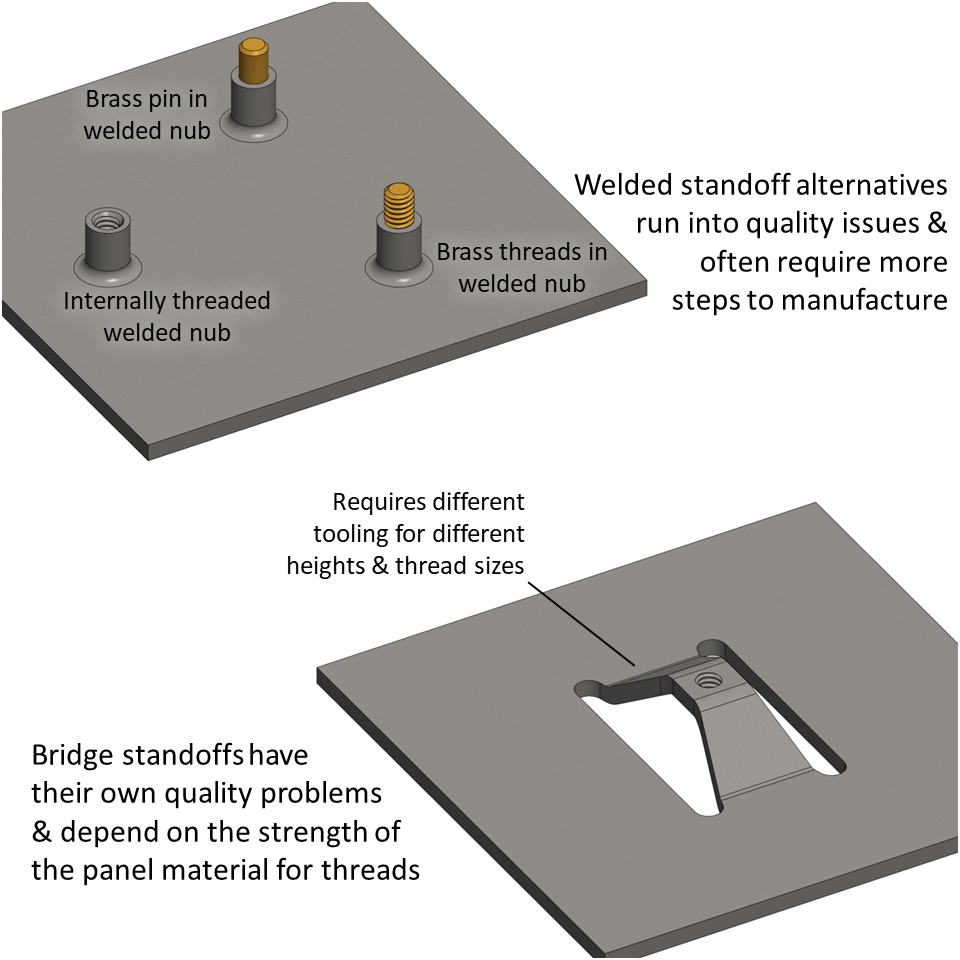

Alternatives to self-clinching standoffs may provide cheaper solutions, but quality & process problems hold them back.

Alternative Solutions

Some prebuilt PCs have integrated standoffs or ‘nubs’ designed into the housing to minimize the number of loose parts. While this may be cost effective for a mass-produced assembly, it limits the opportunity for customization. For custom PCs, it wouldn’t be reasonable to develop several cases with standoff nubs in every possible location for different components. Fasteners allow for more freedom of placement with concealed head clinch features maintaining a continuous, level surface on the outside of the housing.

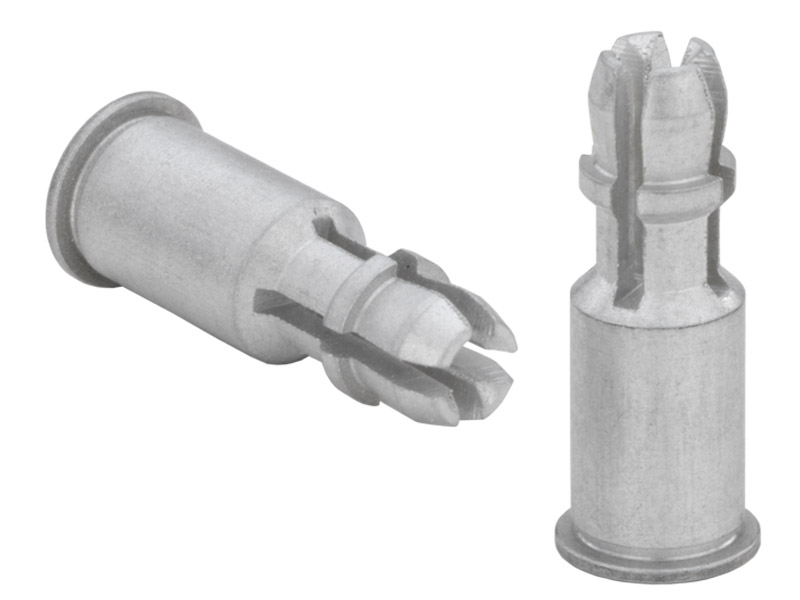

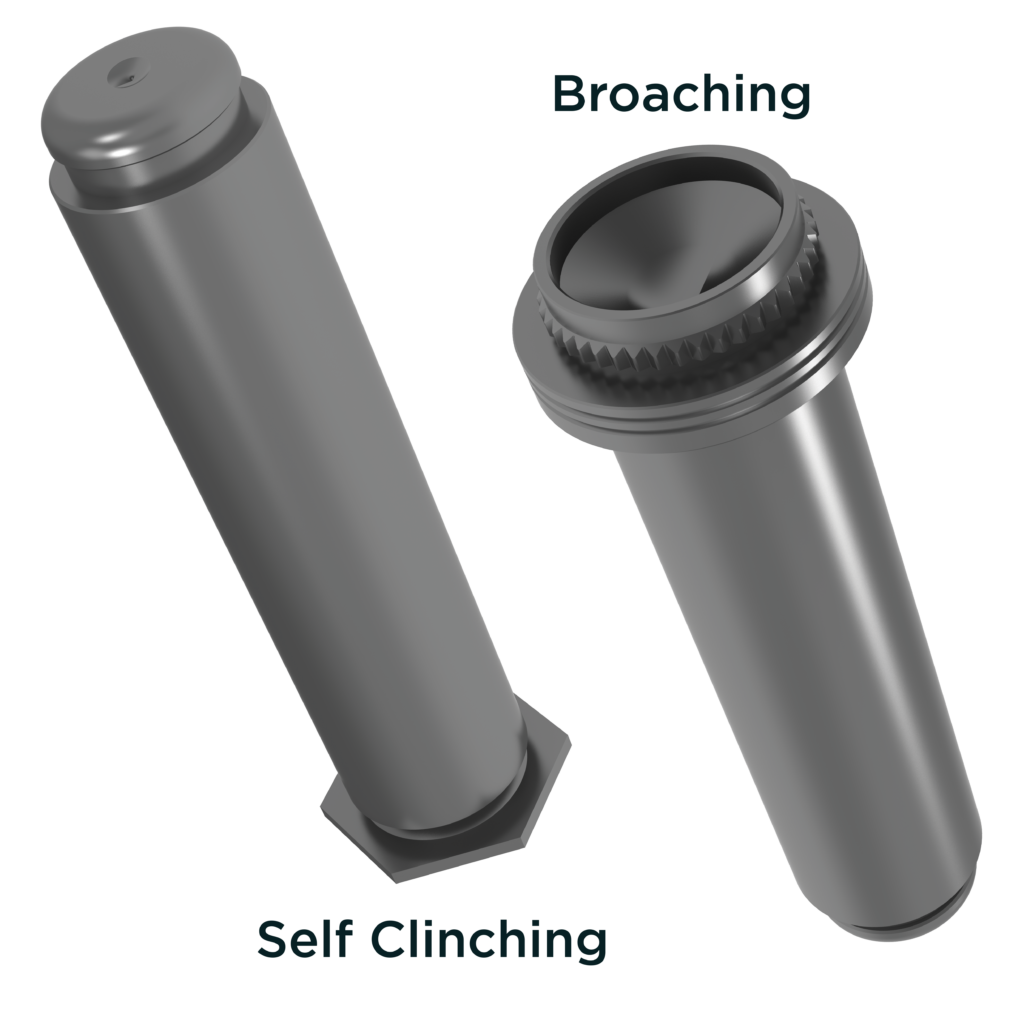

Common Attachment Technologies

On the manufacturing side, if a company has several models of prebuilt PCs, greater placement flexibility can be achieved by using self clinching standoffs. They can decrease tooling or assembly costs and facilitate production modifications for new designs. Broaching and surface mounted (SMT) standoffs allow press fit or soldered attachment points for spacing an additional panel or component above a circuit board in a PCB-to-PCB junction.

Relevant products from PEM:

Explore PEM brand standoffs in our Product Finder:

To learn more about PEM standoffs, visit the SO Datasheet or SSA Datasheet for self-clinching and K Datasheet for broaching and SMT options.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736