CKS-256-1

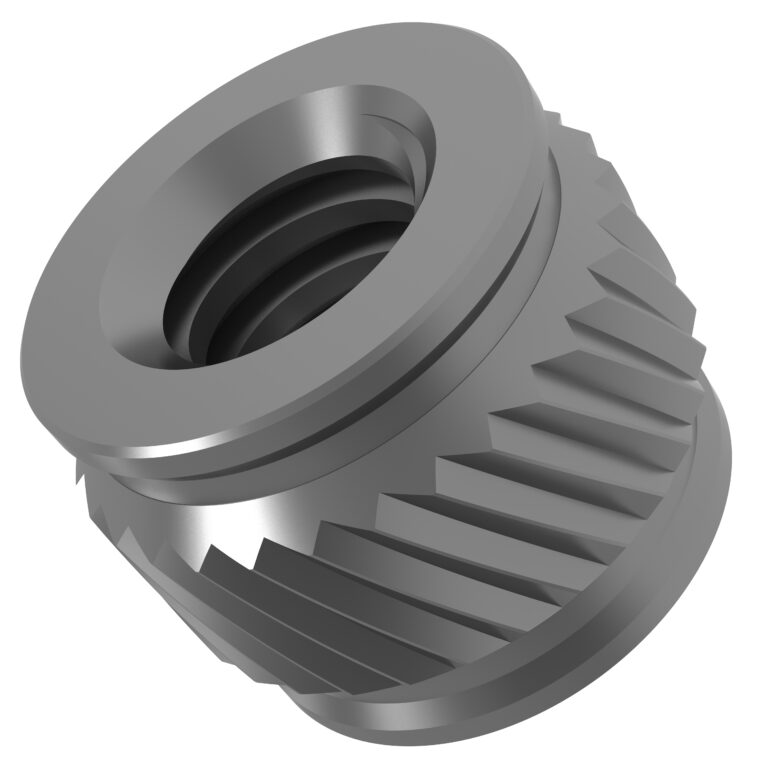

CASTSERT® press-in inserts

CKS-256-1

CASTSERT® press-in inserts

CASTSERT® press-in inserts for castings and soft metals

• Designed for flush installation with flat punch and anvil into blind holes or thru-holes • Process cost savings vs. coil inserts or thread tapping • Installed into drilled holes or as-cast holes with low draft angle • Pilot for rapid seating and self-alignment • Symmetric for auto-feed capability

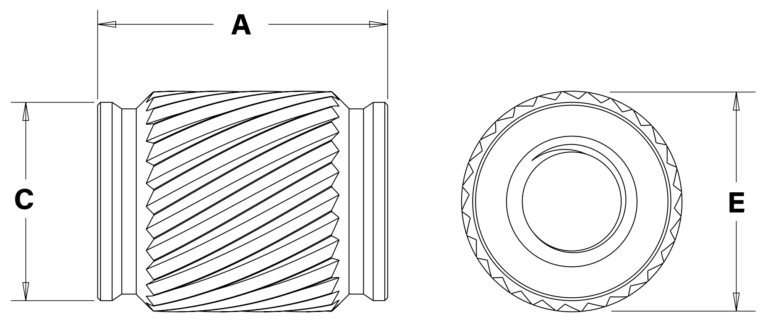

Specifications

- Fastener Material

- 300 Series Stainless Steel

- Standard Finish

- Passivated and/or tested per ASTM A360

- After Knurl E Nom.

- .196

- Application Type

- Castings and soft metals HRB 70 / HB 125 or less

- Brand

- PEM

- Length A ±.005″

- .125

- Min. Dia. H of Tapered Hole at Length R

- .180

- Min. Dist. Hole C/L to Edge

- .151

- Min. Sheet Thickness R

- .130

- PEM Product Family

- CK

- Pilot C Max.

- .179

- Product Type

- Inserts

- Straight Hole Dia. D +.003″ -.000″

- .188

Installation & Performance Data

| PART NUMBER | TEST SHEET MATERIAL | INSTALLATION (lbs.) | PULLOUT (lbs.) | TORQUE-OUT (in. lbs.) |

|---|---|---|---|---|

| CKS-256-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 920 | 65 | 19 |

| CKS-256-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1415 | 135 | 19 |

| CKS-440-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1100 | 75 | 36 |

| CKS-440-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1615 | 145 | 36 |

| CKS-632-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1700 | 180 | 54 |

| CKS-632-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 2200 | 280 | 54 |

| CKS-832-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1820 | 220 | 74 |

| CKS-832-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 3415 | 530 | 74 |

| CKS-032-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 2810 | 250 | 144 |

| CKS-032-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 4114 | 670 | 144 |

| CKS-0420-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 5010 | 570 | 273 |

| CKS-0420-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 6710 | 1345 | 273 |

| Notes: | ||||

| • Performance data in drilled straight hole condition with recommended hole tolerances in JIS H 5302 Grade ADC12 Die-cast Aluminum. | ||||

| • ADC12 material hardness recorded at Hardness 70 HB (Hardness Brinell 70). | ||||

| • Performance data collected from a sample size of 28 pieces from production lot. | ||||

| • Grade 12.9 Socket Head Cap Screws failed in Torque for all samples. Torque-out data shown is average bolt breakage. | ||||

| • Pullout data varies greatly part to part as common with cast metals. Published data is the minimum force to pull insert out of sheet in the 28 piece sample. |

| PART NUMBER | TEST SHEET MATERIAL | INSTALLATION (lbs.) | PULLOUT (lbs.) | TORQUE-OUT (in. lbs.) |

|---|---|---|---|---|

| CKS-256-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 920 | 65 | 19 |

| CKS-256-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1415 | 135 | 19 |

| CKS-440-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1100 | 75 | 36 |

| CKS-440-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1615 | 145 | 36 |

| CKS-632-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1700 | 180 | 54 |

| CKS-632-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 2200 | 280 | 54 |

| CKS-832-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 1820 | 220 | 74 |

| CKS-832-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 3415 | 530 | 74 |

| CKS-032-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 2810 | 250 | 144 |

| CKS-032-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 4114 | 670 | 144 |

| CKS-0420-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 5010 | 570 | 273 |

| CKS-0420-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 6710 | 1345 | 273 |

| Notes: | ||||

| • Performance data in drilled straight hole condition with recommended hole tolerances in JIS H 5302 Grade ADC12 Die-cast Aluminum. | ||||

| • ADC12 material hardness recorded at Hardness 70 HB (Hardness Brinell 70). | ||||

| • Performance data collected from a sample size of 28 pieces from production lot. | ||||

| • Grade 12.9 Socket Head Cap Screws failed in Torque for all samples. Torque-out data shown is average bolt breakage. | ||||

| • Pullout data varies greatly part to part as common with cast metals. Published data is the minimum force to pull insert out of sheet in the 28 piece sample. |

| PART NUMBER | TEST SHEET MATERIAL | INSTALLATION (kN) | PULLOUT (N) | TORQUE-OUT (N•m) |

|---|---|---|---|---|

| CKS-M2.5-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 4.1 | 300 | 2.2 |

| CKS-M2.5-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 6.3 | 600 | 2.2 |

| CKS-M3-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 4.9 | 340 | 4.1 |

| CKS-M3-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 7.2 | 660 | 4.1 |

| CKS-M4-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 8.1 | 800 | 8.4 |

| CKS-M4-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 15.2 | 2100 | 8.4 |

| CKS-M5-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 12.5 | 1120 | 16.3 |

| CKS-M5-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 18.3 | 3000 | 16.3 |

| CKS-M6-1 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 22.3 | 2550 | 30.8 |

| CKS-M6-2 | ADC12 DIE CAST ALUMINUM (A383 EQUIVALENT) | 30.3 | 6000 | 30.8 |

| Notes: | ||||

| • Performance data in drilled straight hole condition with recommended hole tolerances in JIS H 5302 Grade ADC12 Die-cast Aluminum. | ||||

| • ADC12 material hardness recorded at Hardness 70 HB (Hardness Brinell 70). | ||||

| • Performance data collected from a sample size of 28 pieces from production lot. | ||||

| • Grade 12.9 Socket Head Cap Screws failed in Torque for all samples. Torque-out data shown is average bolt breakage. | ||||

| • Pullout data varies greatly part to part as common with cast metals. Published data is the minimum force to pull insert out of sheet in the 28 piece sample. |

Inventory

| Distributor | Quantity | Contact | Phone | Address | Locations |

|---|