What is Self Clinching Technology?

Production Fastening Revolutionized.

Self clinching technology has revolutionized production fastening and put PEM® on the map as a global industry leader. It’s a clean, energy-smart alternative to conventional methods such as spot weld – with proven performance for today’s most challenging applications.

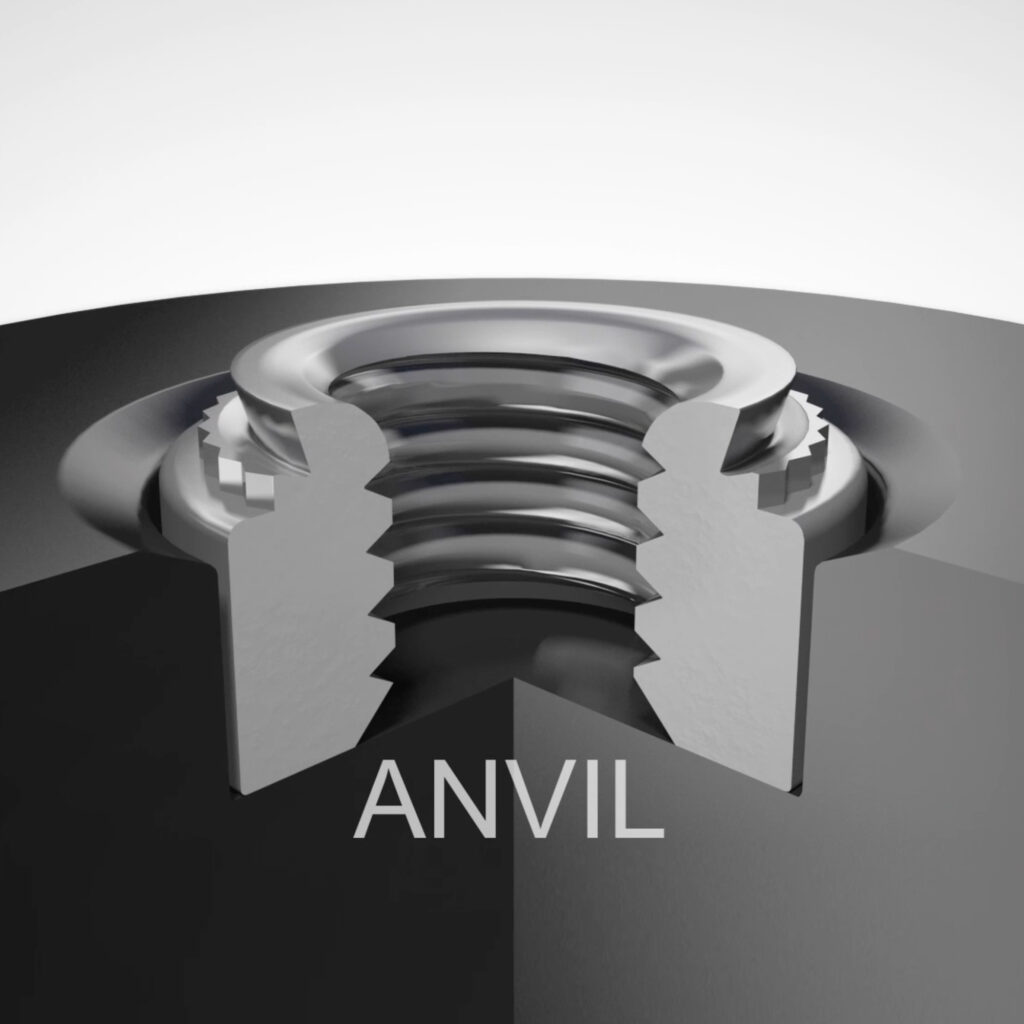

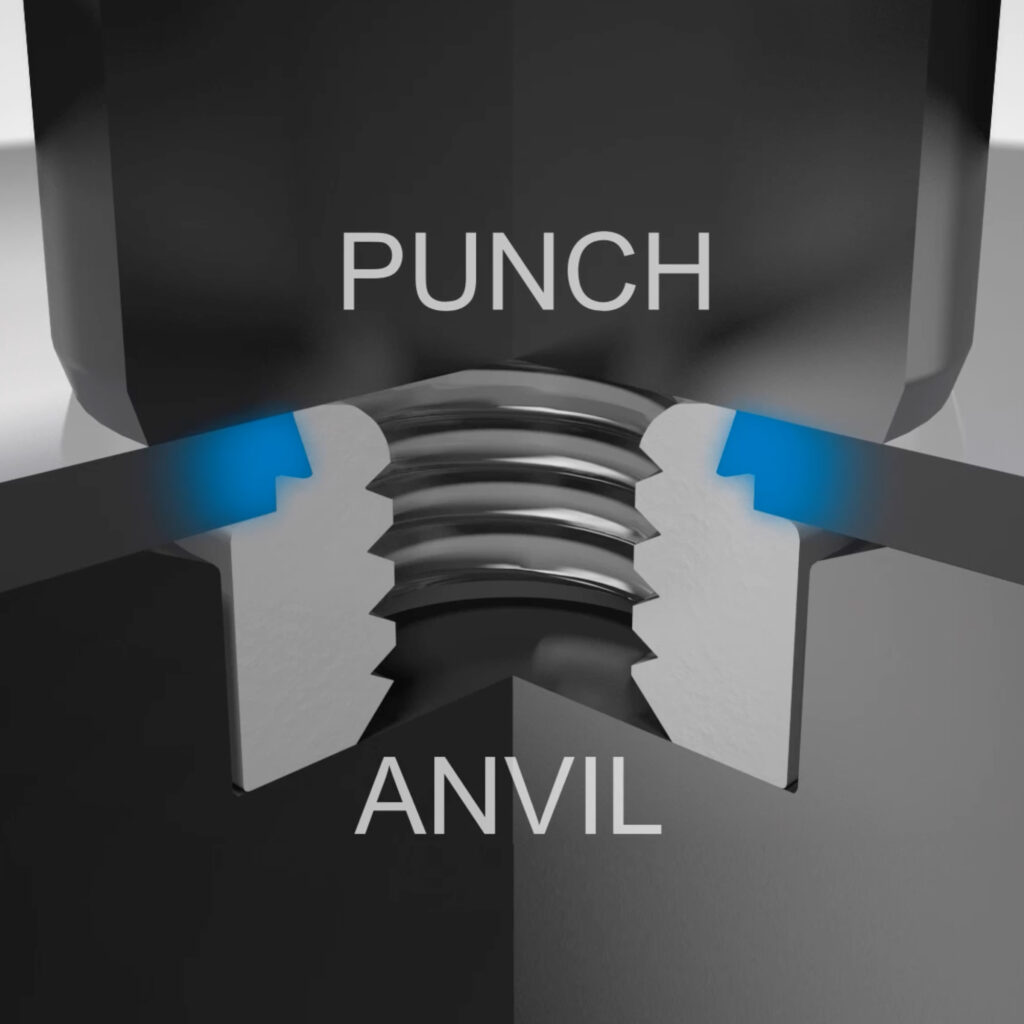

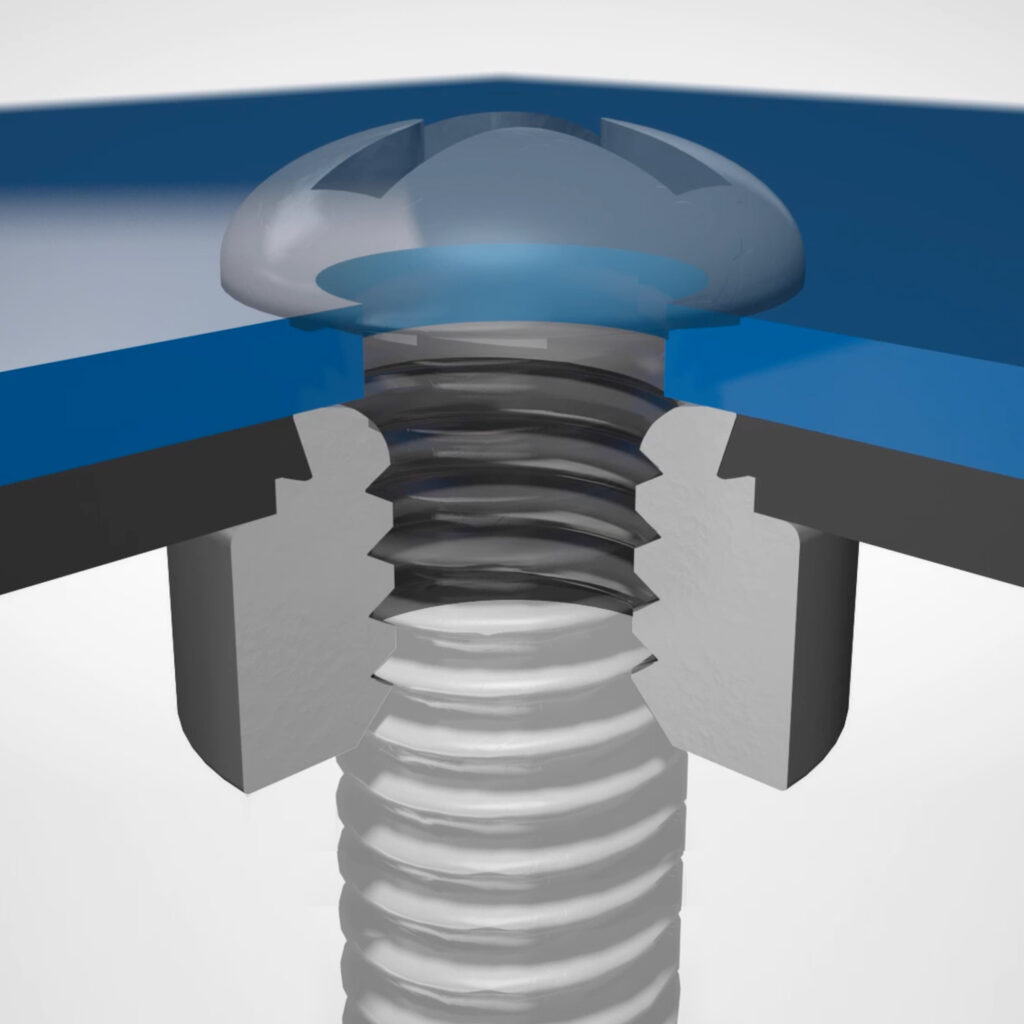

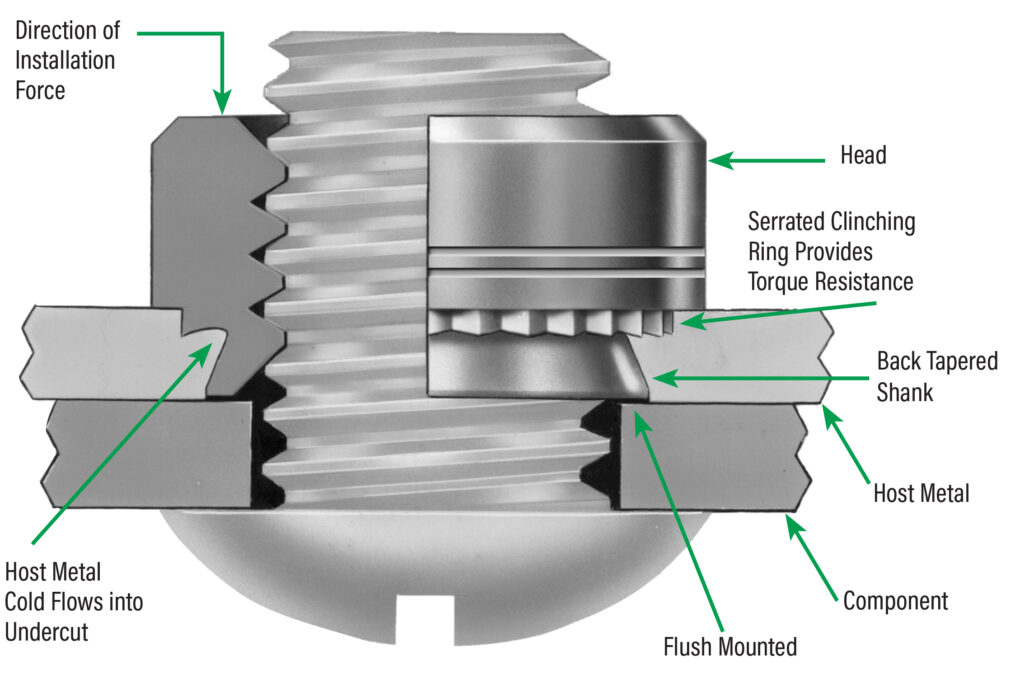

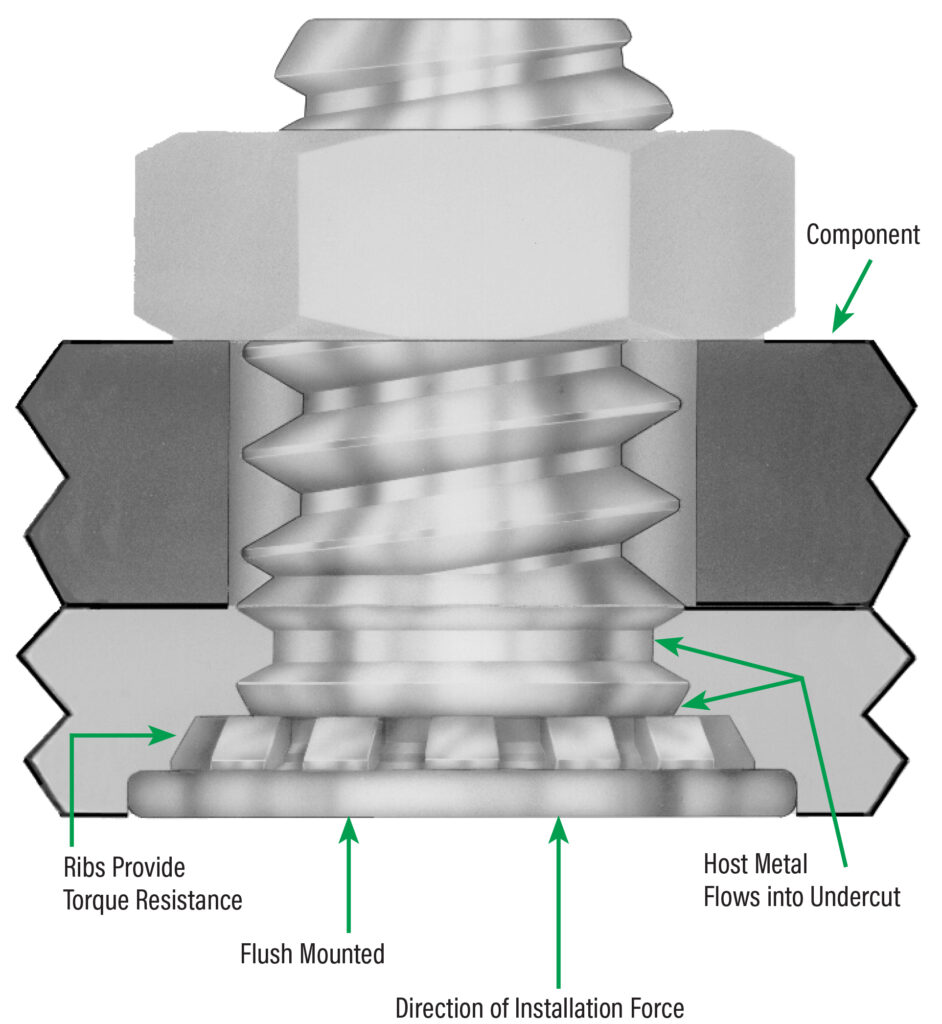

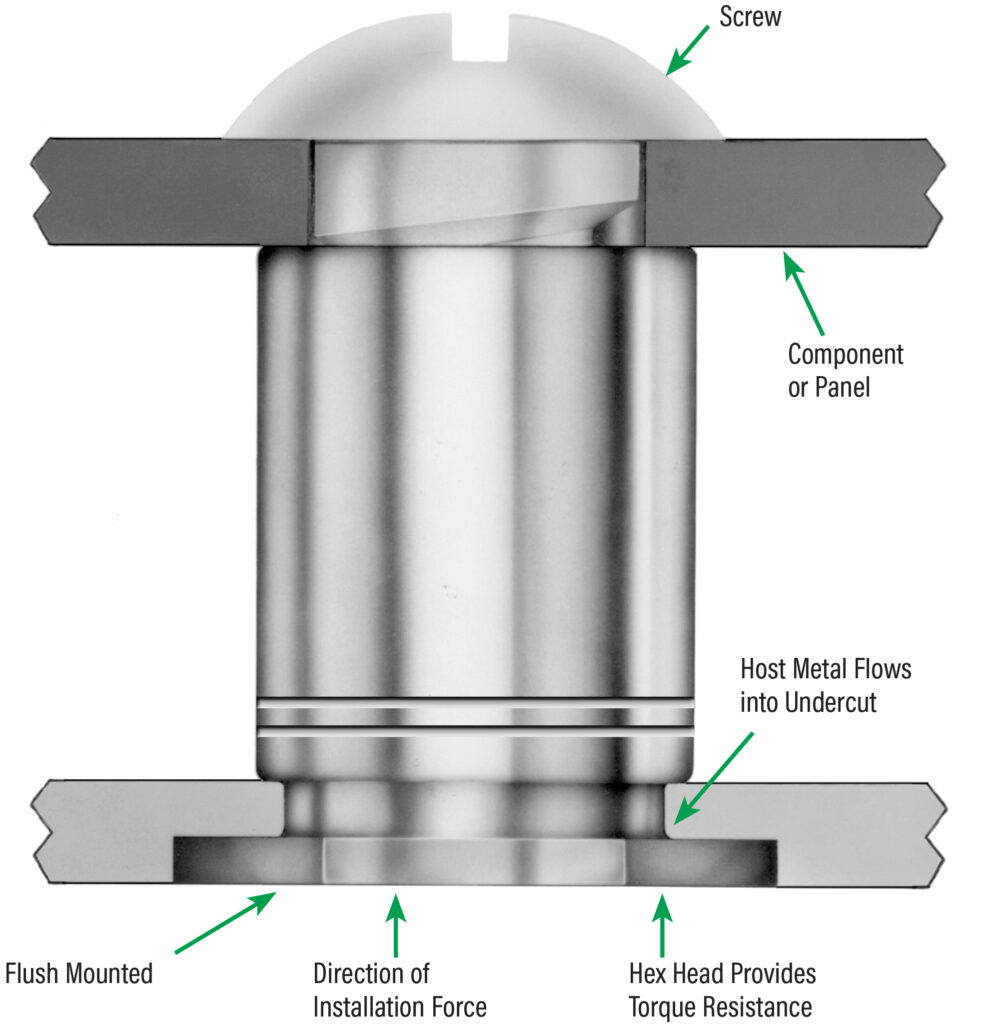

When pressed into ductile material, a self clinching fastener (commonly referred to as a clinch nut or press nut) displaces the host material around the mounting hole, causing it to cold flow into a specially designed annular recess in the shank or pilot of the fastener.

A serrated clinching ring, knurl, ribs, or hex head prevents fastener rotation in the host material once inserted – becoming a permanent part of the piece into which it’s installed.

The result — an innovative fastening solution that saves you time, money, and is better for the environment.

How It Works

Self clinch in 3 easy steps.

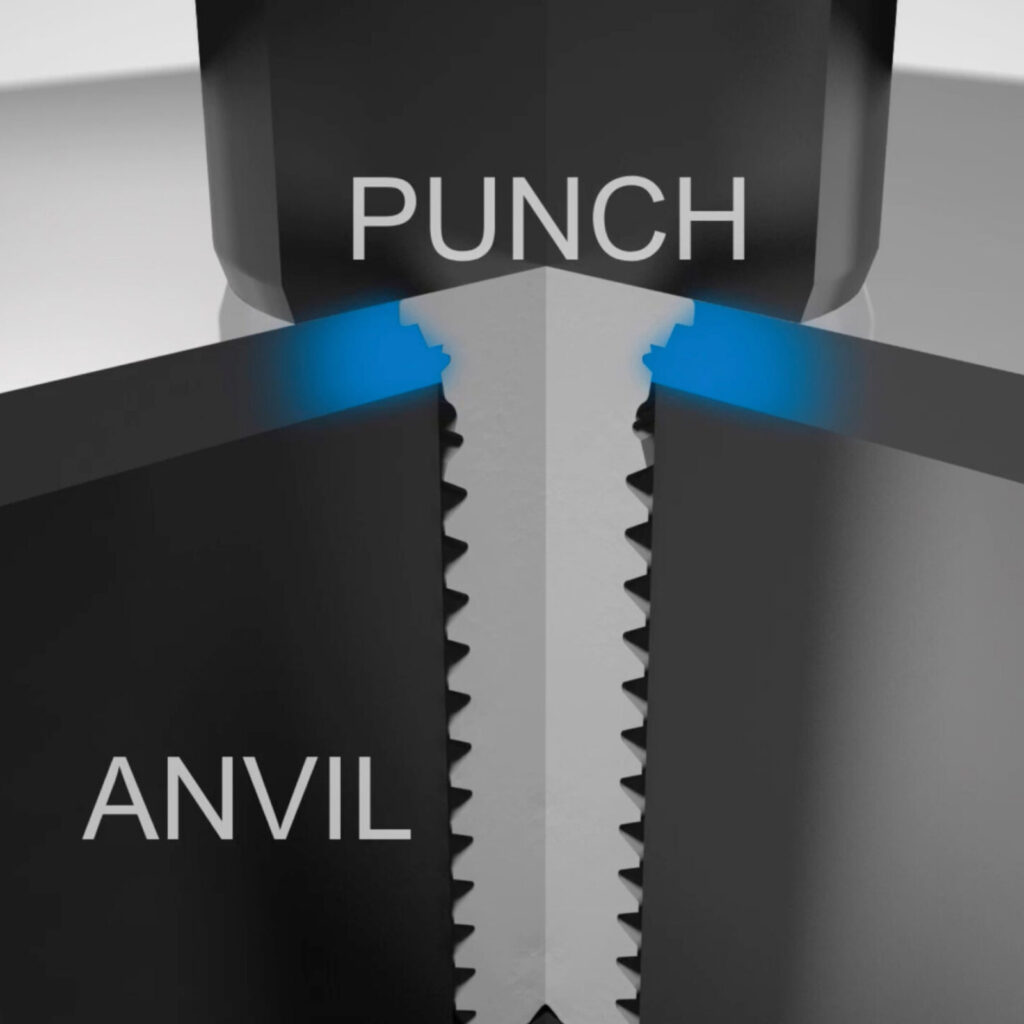

Gain big efficiency on the assembly line with self clinching technology. In just three easy steps, self clinching fasteners install with any parallel acting press that can be adjusted to optimum installation forces.

Step 1.

Place fastener into the anvil hole and place the mounting hole over the shank of fastener.

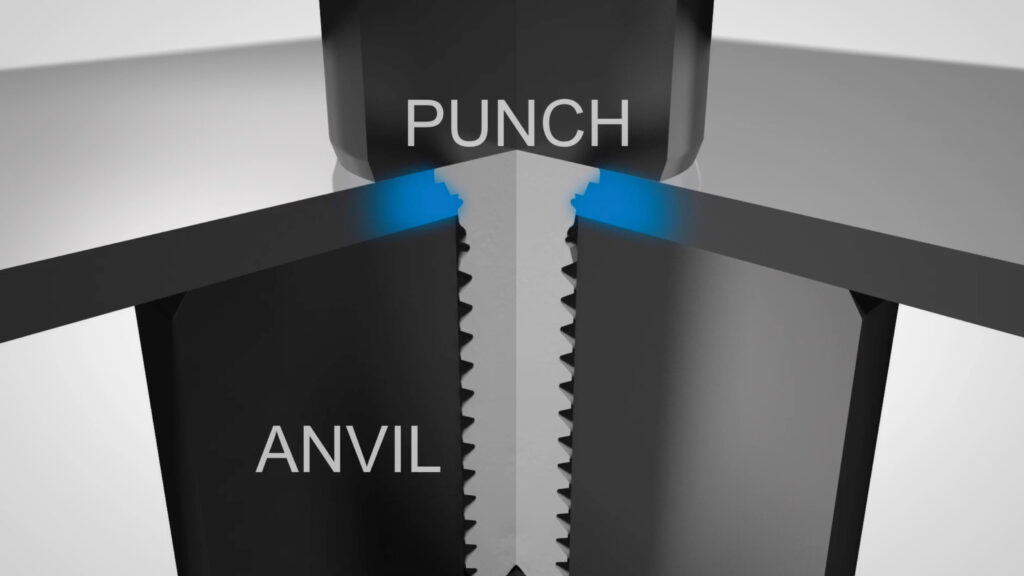

Step 2.

With installation punch and anvil surfaces parallel, apply squeezing force until the head of the clinch nut comes in contact with the sheet material.

Step 3.

Install the mating piece from the side opposite the head of the fastener.

The Anatomy of Self Clinching.

Self Clinching Nut (Press Nut)

Self Clinching Stud

Self Clinching Standoff

Benefits of Self Clinching

Versatile. Cleaner. Stronger. Discover the advantages of self clinching technology.

- Increased thread strength

- No weld splatter

- Install into dissimilar materials

- Panel and/or fastener can be pre-finished

- No introduction of thermal stresses

- Reduced environmental concerns

- Lower energy consumption

- Improved positioning of fastener

- Reduced installation cycle times

- Can be installed in-die

Application Examples by Industry

Industry Applications

Consumer Electronics

Application

Mobile Phone

PEM® Solution

MSO4™ Standoffs

Following the switch from weld fasteners to MSO4™ standoffs, this next-gen phone used a lighter 0.3mm aluminum chassis as they no longer needed to use similar materials for welding.

Datacom/Telecom

Application

Network Storage Chassis

PEM® Solution

SO™ Standoffs

The customer previously used weld standoffs but experienced challenging weld marks on the customer-facing side of the product. Switching to a self clinching standoff eliminated the issue and improved cosmetics.

Industrial

Application

Laser Level

PEM® Solution

Special Clinch Stud

The use of spot weld studs caused significant assembly problems including misplaced hardware, perpendicularity issues, and weld splatter. Switching to a special clinch stud eliminated challenges and provided a cleaner, environmental-friendly assembly process.

Medical

Application

Instrument Front Panel

PEM® Solution

SF™ SpotFast® Fasteners

Tack weld operations required extra costs and processing from a third-party contractor. Post-weld cleaning was also needed before final painting operation. Switching to SpotFast® fasteners eliminates secondary operations, and the panel can proceed straight to paint finishing.

FastenerClass® Technical Training

Learn how to test and evaluate fastening designs with support from PEMedge® Services and learn how to choose the best assembly solution for your applications.

Featured Courses

- Intro to Self-Clinch Theory

- Fasteners for Stainless Steel Panels

- Surface Mount Technology (SMT) vs. Broach

- Fasteners for Compact Electronics

- Innovative Solutions for Design

Weld vs. Self Clinch Comparison Chart

Compare Self Clinching to Weld

See why innovative self clinching fasteners, such as clinch nuts or press nuts, are the smart alternative to conventional tack weld fasteners. Achieve greater versatility, durability, performance, and cost savings – with installation methods that are cleaner and safer for the environment.

| Benefit | Self Clinching | Weld |

| Cost-Saving In-Die Installation | Single-step in-die installation capability eliminates secondary operations, increases throughput, cuts costs | Secondary tack weld operations require more manufacturing time and energy consumption |

| Fasten Dissimilar Materials | Able to be fastened into several materials like common steel, HSS, sandwich panels, hot forming steel, aluminum, magnesium, die-cast material, carbon fiber | Welding can only be performed on similar materials |

| Water-Tight Seals | Creates a reliable leak-proof seal in aluminum and steel applications, prevent water intrusion | Water-tight seals are difficult to achieve with spot weld fasteners, leading to water damage and corrosion from elements |

| Stronger Joints | The lack of a heat source (required for weld nuts) produces no weak points due to thermal effect | The welding process increases the chance for thermal stress or annealing |

| Reduced Weight | A mechanically attached nut is typically lighter than a weld nut while maintaining similar performance | The welding process adds additional weight to the part |

| No Coating or KTL Effect | Can install a coated fastener into a panel without disturbing the coating or KTL of either part | Welding process burns off existing coatings and creates opportunity for corrosion |

| Full-Service Technical Support | PEM® provides comprehensive support – applications engineering, tooling, manufacturing, training, and tech support | Weld fastener manufacturers typically do not provide design and technical support |

Issues with Welding

The Challenges with Weld

- Time-consuming and labor-intensive process

- Increased energy consumption from secondary operations

- Weakened joint strength from spot weld heat

- Cannot weld dissimilar materials

- Process can add additional weight to product

- Difficult to achieve water-tight seals on weld nuts

- Welding process requires technical skillset

- Opportunities for corrosion from coatings burning off

Featured and Related Resources

Types of Self Clinching Fasteners

Self clinching technology can be applied to many types of fasteners – combining the benefits of self clinch with a broad range of fastener functionality. Our standard fastener portfolio meets many design requirements, or work with a PEM® application engineer for a custom solution.

Featured and Related Resources

Installation

Whether you have a medium-volume or high-volume application, there are cost-effective and energy-saving solutions available for self clinching fastener installation. Learn more about Heager® robotic/manual installation and PEMSERTER® in-die installation.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736