Choosing a Thread Size

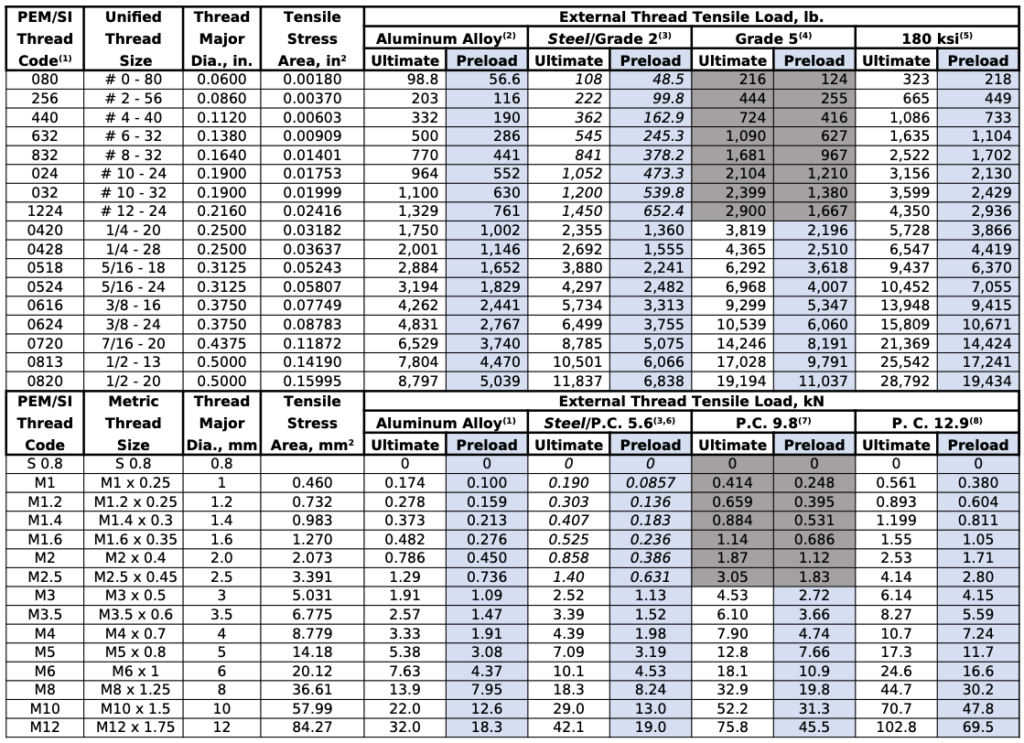

PennEngineering offers threaded fasteners with metric thread sizes ranging from S 0.8 to M12 and Unified sizes ranging from #0 to ½”.

Selecting a Thread Size

1

Maximum Axial Load

The first piece of information needed to select a thread size is the maximum axial load the fastener must withstand.

2

Minimum Fastener Weight

The second piece to consider is whether there is a need to minimize fastener weight. If low fastener weight is important, then high strength steel or aluminum should be considered for the fastener material.

The tables below give axial loads for each thread size and four material strength assumptions as follows:

- Heat treated aluminum alloy with tensile strength of 55 ksi and 36% of steel weight

- Un-heat treated steel with tensile of 60 ksi for small sizes, PC 5.6/Grade 2 for larger sizes

- Heat treated steel PC 9.8 at 900 MPa for metric and Grade 5 at 120 ksi for Unified

- High strength heat treated steel PC 12.9 at 1220 MPa for metric and 180 ksi for Unified

How to read the values

Two values are given for each of the four material strength options.

The first is the ultimate axial load which can be compared to the anticipated maximum axial load multiplied by the safety factor used.

The second load value is typical preload and is based on 75% of min yield strength, which is common practice for selecting target preload and tightening torque. This load, multiplied by the coefficient of friction between the clamped parts can be compared to the anticipated maximum transverse force the joint needs to withstand.

In combination with other available tools on our website for selecting the type of product, knowing the thread size needed will allow customers to drill down to a specific part number to check pricing and availability.

Notes

- Thread codes shown are used for all PEM Brand and SI Brand products. Atlas brand thread codes are different.

- Load for aluminum alloy based on ultimate stress of 55 ksi (379.2 Mpa) and yield stress of 42 ksi (289.6 Mpa)

- Loads based on SAE J429, Grade 2 ultimate stress of 74 ksi and yield stress of 92 ksi for thread sizes 1/4-20 and larger. Unified sizes #12-24 and smaller and metric sizes M2.5 and smaller based on ultimate of 60 ksi (413.7 MPa) and yield of 36 ksi (248 Mpa). These values are in italics and are typical of low carbon steel screws which have not been heat treated.

- Loads based on SAE J429, Grade 5 ultimate stress of 120 ksi and yield stress of 58 ksi

- Loads based on ultimate stress of 180 ksi and yield stress of 162 ksi which is typical for socket screw products in the US

- Loads based on ISO 898-1, Property Class 5.6 ultimate stress of 500 Mpa and yield stress of 300 Mpa for M3 and larger

- Loads based on ISO 898-1, Property Class 9.8 ultimate stress of 900 Mpa and yield stress of 720 Mpa

- Loads based on ISO-898-1, Property Class 12.9 ultimate stress of 1220 Mpa and yield stress of 1100 Mpa

- All preloads are based on stress on the tensile stress area of 75% of yield stress

- Gray shading denotes combinations of thread size and strength level that are not commercially available.

Products

Final design and product selection must always be validated by the responsible design engineer. Some PennEngineering® product types with special design features have lower axial strength than shown in the table above. Examples include type FH and FHL studs, types F and F4 flush nuts and types U, UL, FEO, FEOX, FF and FEX miniature nuts and locknuts.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Email: [email protected]

U.S. 1-866-236-4063

Europe: 353-91-747100

China: 86-21-5868-3688

Singapore: 65-6-745-0660