Defense

Rugged. Reliable.

Whether it’s a standard catalog part or a custom-engineered solution, PEM® fasteners stand up to the rugged conditions required for a broad range of defense applications and related applications in military/government, aerospace, and beyond.

Many PEM® nuts, studs, standoffs and pins have the certifications needed to meet defense and military specifications:

- Department of Defense Qualified Suppliers List for Manufacturers (QSLM) – Class 2 and Class 3 Threaded Fasteners

- ISO 9001:2015 Certified – global PEM® locations in U.S., Singapore, Germany

Radar Systems

Military Equipment and Vehicles

Weapons

Drone Technology

Aircraft

Missile Defense

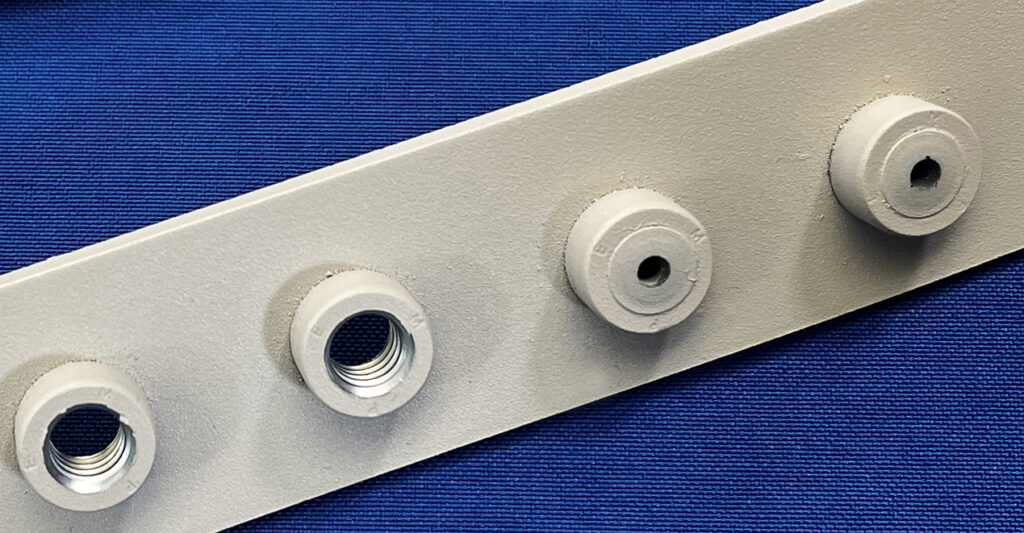

Component Plates

Unmanned Aerial Vehicles (UAV)

Defense

By the Numbers

18,000

Unique consumers

Nearly 18,000 unique consumers of PEM® parts per year.

1 million

Unique users

Nearly 1M unique users research PEM® products per year.

20,000

Unique PEM® part numbers

Nearly 20,000 unique PEM® part numbers produced annually.

Innovations Lab. Where Anything is Possible.

See what’s possible in the PEM® Innovations Lab. Here, collaboration between customers and PEM® engineers drives new ideas and new product innovations to advance performance for even the most challenging applications.

help center

Have a project? Let’s get started.

Have an application question? Talk to a PEM® engineer and discover the most reliable, cost-effective fastening solution for your biggest challenge.

Request free product samples and see how our innovative fastener designs and technologies can help save you time, money, and resources.

Gain valuable insights from our extensive resources center. Includes product catalogs, CAD drawings, data sheets, videos, engineering guides, and more.

Find information on environmental and government compliance, quality approvals and certifications, and browse other regulatory resources.

Related Solutions

The Power to Connect

See how PEM® delivers engineering innovation with global services and capabilities that expand beyond the defense market.

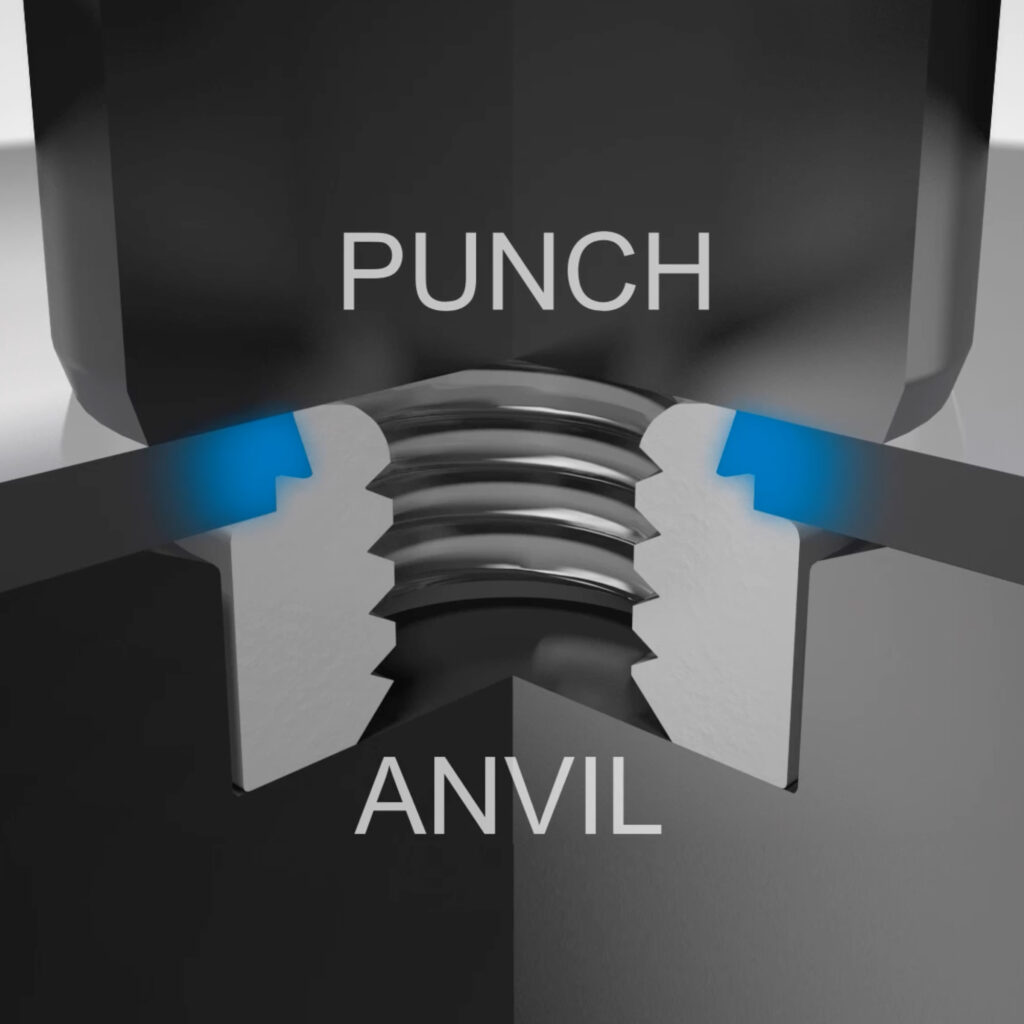

Self-Clinching Technology

Self-clinching technology from PEM® is the idea that revolutionized production fastening. A smart alternative to spot and tack weld products, self-clinching capabilities can be applied to many types of fasteners, including clinch nuts, studs, and standoffs – combining powerful benefits with a broad range of fastener functionality. It’s innovation that enables fewer parts, less total assembly time, and lower installed costs.

- Provides strong threads in metal as thin as .008” / 0.2 mm

- Installs using any parallel acting squeezing force

- High pushout and torque-out resistance

- Reverse side of metal sheet remains flush

- No re-tapping needed

- Low total installed costs

Industrial and

Commercial

Whether you want to optimize assembly, improve product reliability, or ensure better performance for your demanding industrial or commercial application, you can find the right fastening solutions for structural component attachment or other assembly requirements with PEM®.

Versatility and Power.

- Electrical Equipment

- Alternative Energy Equipment

- Construction Equipment

- Marine, Rail and other Transportation

- Special Industry Machinery

PEMEDGE® Services

Gain a market edge.

Benefit from the expertise of trained engineers with this array of complimentary services. Designed to help improve your product’s cost, quality, time to market, and overall performance, these services advance your products and our world.

APPLICATION ENGINEERING

- Application Review

- Custom Design/Product Development

- Customer Drawings

- Catalog Samples

- 3D Models

- Prototype Development Center

Testing Service

- FEA Analysis

- Mechanical Testing

- Tensile and Compression Strength

- Micro Hardness

- Fastener Joint Cross-Sectioning

- Corrosion and Plating Testing

Teardown Service

- Complete Product Disassembly

- Assembly Structure Assessment

- Identify Alternative Fastening Solutions

- Alternative Fastener Replacement/Testing

- Teardown Report

- Identify Efficiencies/Implementation Plan

FASTENERCLASS® MASTER CLASS

- Free Customized Training Sessions

- Learn from Global Experts

- Live, web-based, and pre-recorded training options available

Standard Classes Include:

- Theory, Best Practices, Application Exploration

- Intro to Self-Clinch Theory

- Proper Fasteners for Stainless Steel Panels

- Surface Mount Fastener Technology (SMT) vs. Broach

Virtual Tech Support

- Connect with a live senior PEM® Engineering expert – you choose the date/time

- Get advanced consult for your application and design questions

- Review drawings and 3D models

- Discuss technical cleanliness needs

- Explore product teardown opportunities

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or call any of the direct phone numbers listed below:

U.S.: 1-866-236-4063

Europe: 353-91-747100

China: 86-21-5868-3688

Singapore: 65-6-745-0660