Captivated Screws | Knob Cap Screws

Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

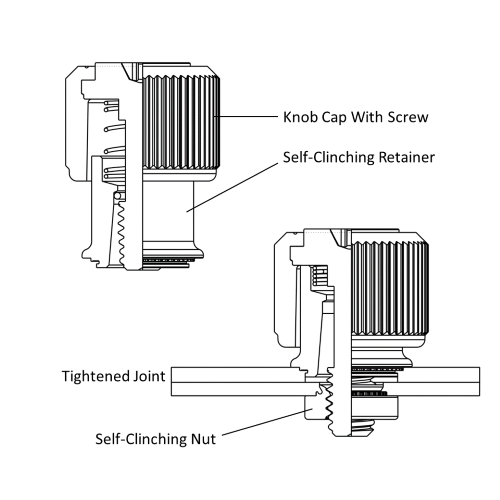

Knob cap screws refer to captive fasteners that feature an exaggerated head, made either from a separate metal component or molded plastic. Given the application requirements, knob cap screws almost guarantee the use of a spring between the head and the retainer. The cap typically has a cavity to envelope the retainer when it’s fully tightened to maximize the outer surface area of the cap while minimizing the over-all height. While most will still have a flat head or Phillips drive in the head, these knobs are meant to be hand-driven without the use of a tool.

Application

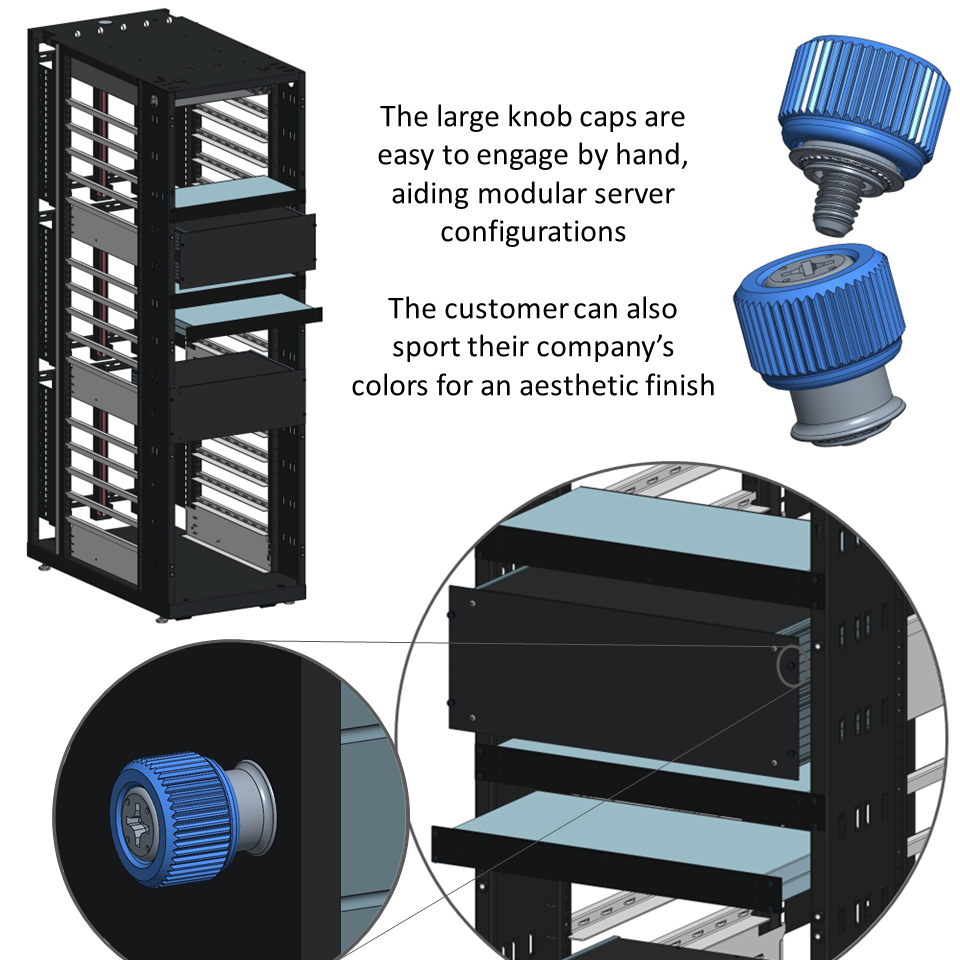

Given the emphasis on tool-free utility, knob cap captive screws are popular in datacom and telecom applications. Internal components in a server rack are highly modular and can be swapped with upgrades on a regular basis. The people who manage the configuration of these components likely have a primary role in the services provided by these servers – meaning they might want a quick, easy way to make changes without requiring a specialized tool kit. This makes knob caps ideal for casual reconfigurations, and a plastic molded cap can provide further customization with proprietary colors. Keep in mind, however, that these custom options are justified by the larger price tag that typically comes with these types of server modules.

A server rack can be more readily modular with knob cap screws, also known as thumb screws.

Alternatively, if a more permanent setup needs to be resistant to tampering, the cap can be replaced with a recessed-head retainer.

Alternative Solutions

As hinted in the application discussion, some cost savings could be made by removing the large knob and opting instead for a larger screw head with fine knurls to maintain tool-less utility, but the further simplification would be the use of loose screws with associated tools. The time tradeoff associated with reconfiguring the server modules is likely offset by the reduced price of production of the module but may not meet cosmetic preferences.

If more tamper resistant screws were a priority for the end user over configurability, a spring-loaded screw with a recessed head flush with the retainer would allow mounting or dismounting with an associated tool.

Common Attachment Technologies

The attachment feature chosen for a knob cap screw is wholly dependent on the application. These captivated fasteners commonly incorporate all the attachment technologies we’ve discussed, and with the associated cost are optimized for the materials of the assembly.

Relevant Products from PEM:

Explore the wide variety of knob cap panel fasteners in our Product Finder:

To learn more, visit the PF Datasheet for a wide variety of knob caps and captivated screws.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736