Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

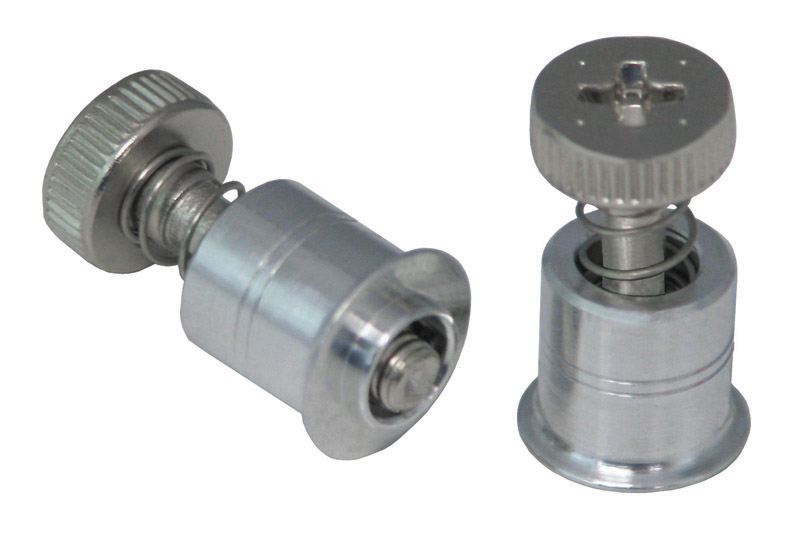

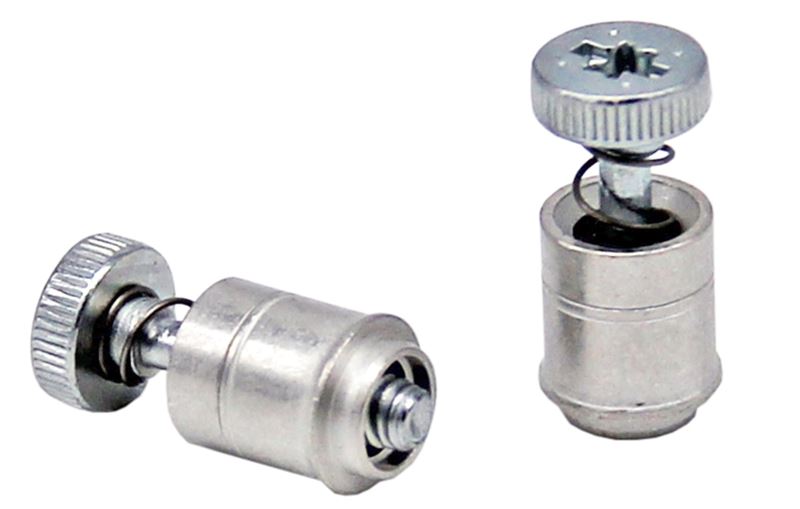

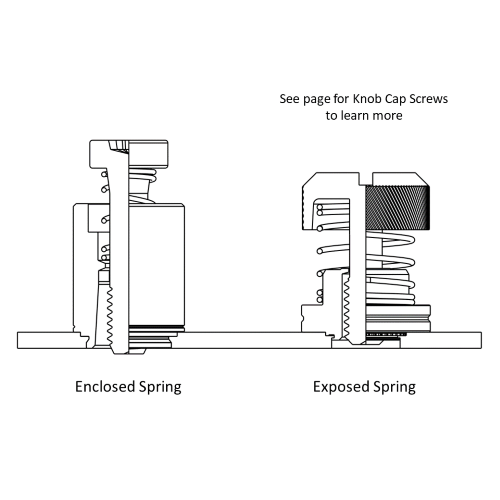

A spring-loaded, captivated screw involves all the same features associated with a simple screw with one additional component. The spring sits between the shoulder of the retainer and the head of the screw, keeping it extended when not engaged with a mating thread. Depending on the application, this spring can accommodate a smaller retainer and surround it or sit inside a larger retainer. The tradeoffs associated with these options are further discussed in the context of knob cap screws.

Application

The mechanical function of the spring is to fully disengage the screw from its mating thread when loosened, with some spring-loaded screws receding past the bottom surface of its panel completely. While this has some benefits for cosmetic requirements such as minimizing the risk of scratching with the screw tip, the primary benefit is the increased ease of mounting and dismounting.

For example, elevators that stop working need to be fixed quickly. Using a spring-loaded screw with a Phillips or flat head drive, service technicians can quickly remove and replace the cover plate to access the elevator controls and make the repair. They also have the added benefit of the recessed screw head, whose flush installation when fully engaged can discourage disengagement by hand.

A spring-loaded screw with a retainer allows for quick engagement & disengagement of an elevator access panel.

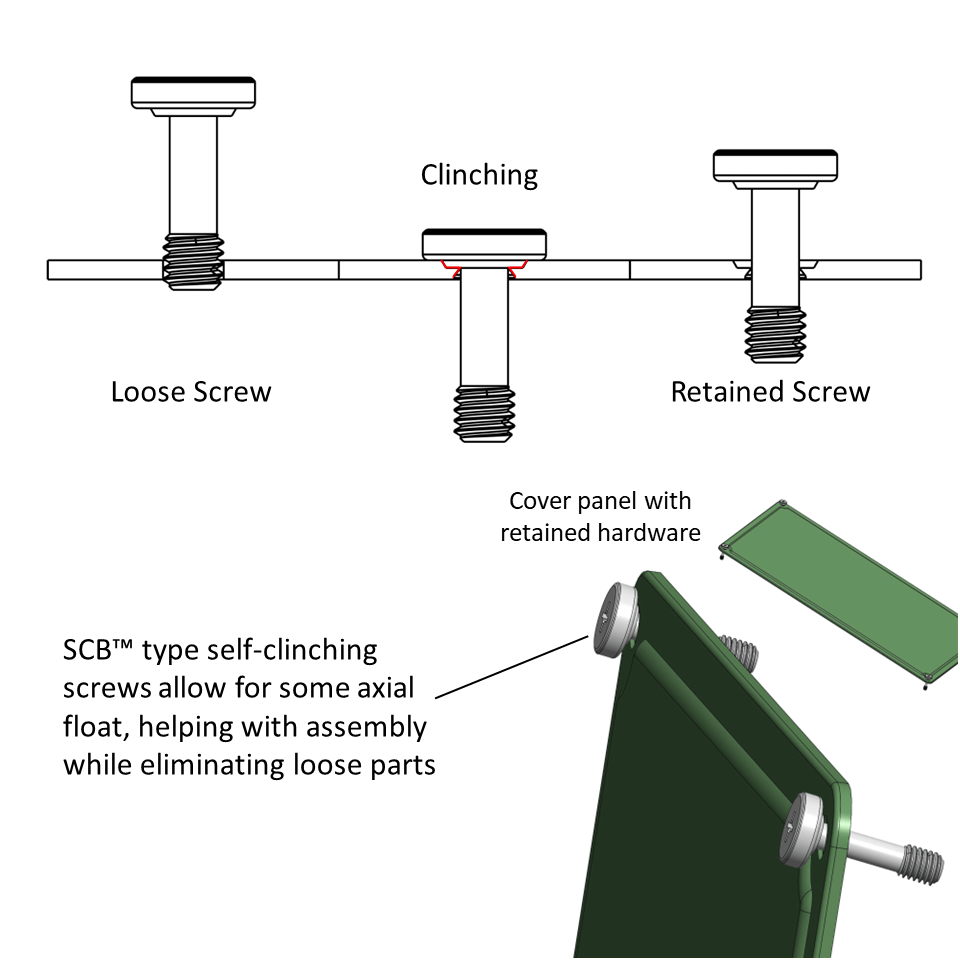

Simple screws may limit cosmetic options, but offer a cost-effective solution for an access panel with no loose hardware.

Alternative Solutions

Loose screws, though less expensive, lead to the possibility of lost screws. More complex hardware like a latched cover with a hinge might be even easier to access but creates more dimensional requirements for the assembly as a whole. This potentially complicates the production process on the side of the elevator manufacturer.

However, while it may be easiest with the included spring to access the elevator controls, the increased cost associated with the assembly of the screw, spring, and retainer can be circumvented with a simple screw and retainer with no spring, perhaps even without a retainer.

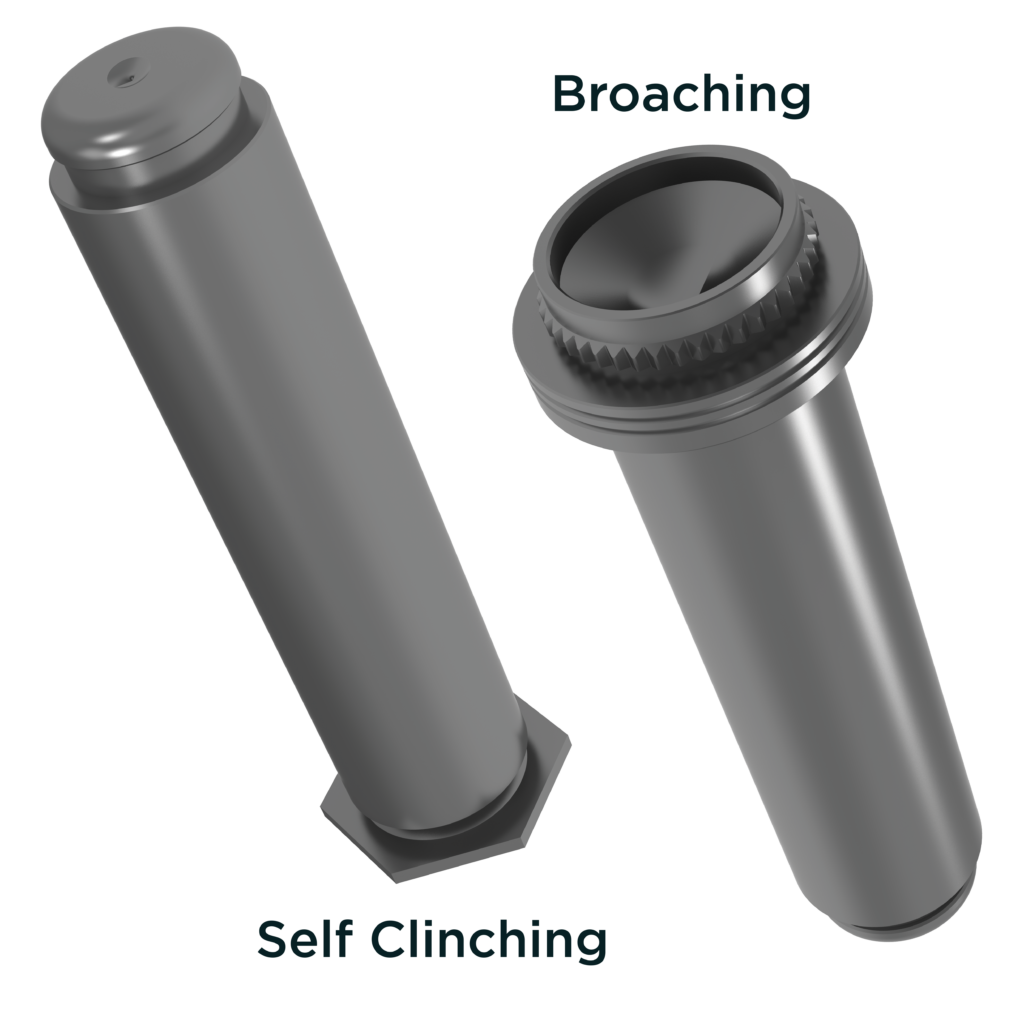

Common Attachment Technologies

Spring-loaded captivated screws are among the most common captivated fasteners with the most options available for specific features and customizations. So it’s no surprise they’re leveraged in many applications using all of the attachment technologies previously discussed.

Relevant Products from PEM:

Explore a variety of options for spring loaded screws in our Product Finder:

To learn more, visit the PF Datasheet for a wide variety of spring-loaded screws.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736