Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

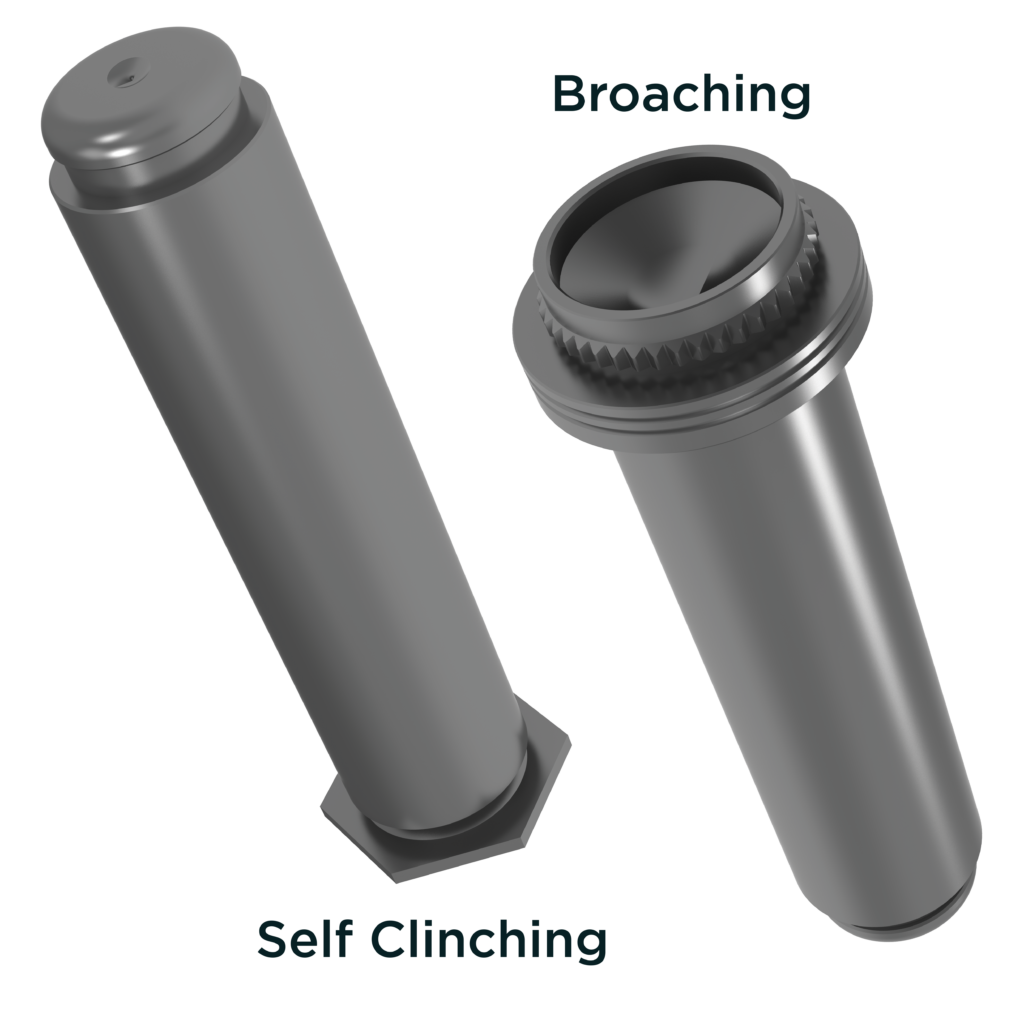

Attachment Technologies

Overview

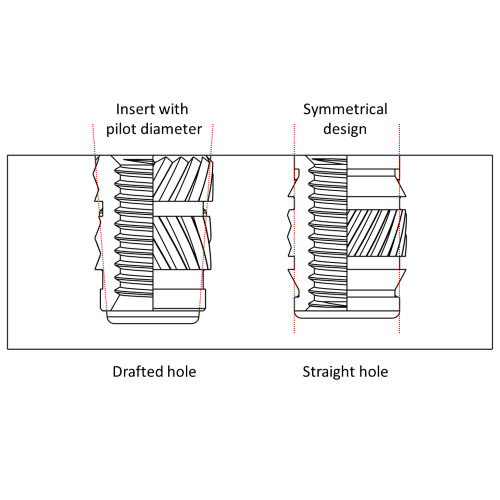

Ultrasonic and heat-staking inserts (also known as heat-set inserts) commonly use both a right hand and a left hand knurl on different sections of the outer diameter to restrict both rotational and axial movement. These knurled regions can stand alone or be paired with barbs to further improve pull-out strength. Since this installation method locally melts the plastic around the insert, the barbs and knurls are better filled than in press-in inserts for a more efficient interference fit. Inserts for a tapered hole have a one-sided pilot diameter with one-way barbs while straight holes can use symmetric insert designs to simplify the production process. These parts are typically cut from round bar stock of brass, aluminum, or stainless steel.

Installation

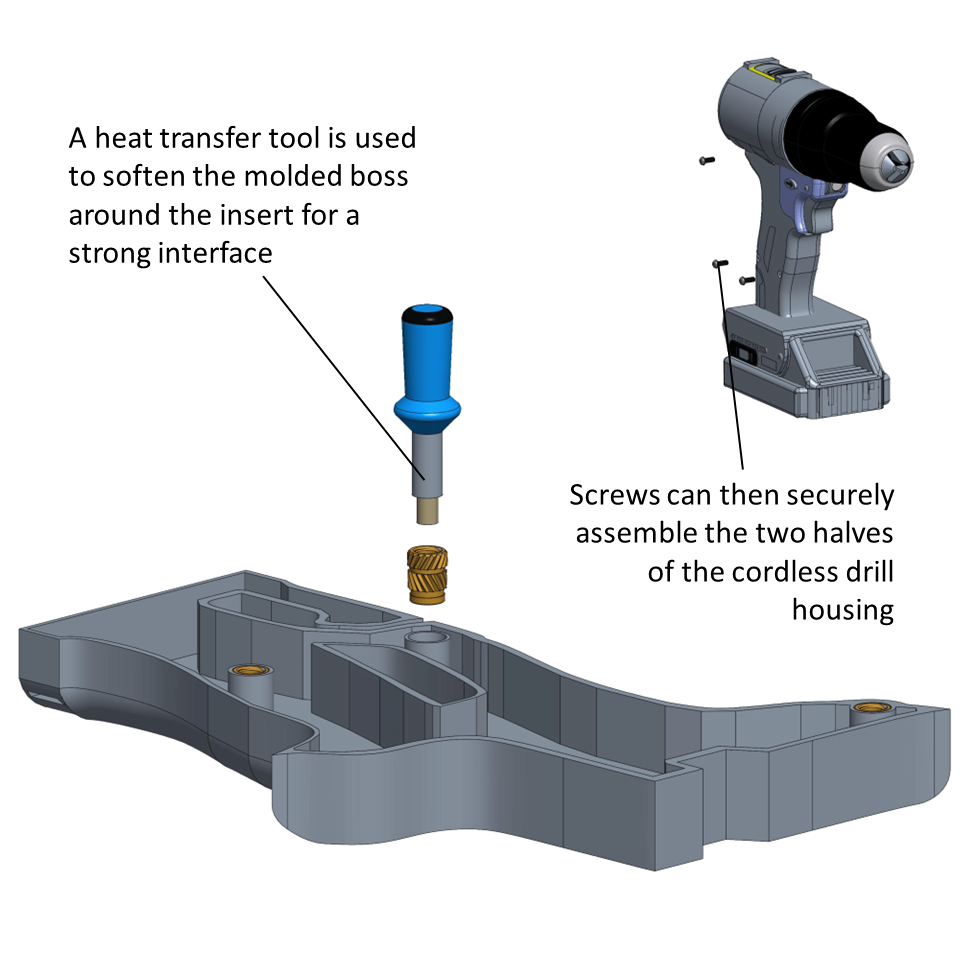

While accomplishing it through different means, both ultrasonic and heat-staking install machines are designed to re-melt material post-mold by transferring heat through the insert. The surrounded plastic then solidifies after reforming to the knurls and barbs of the insert, making for a reliable bond at their interface. Ultrasonic machines induce vibration in the insert at 20kHz, melting a very thin layer of plastic at the insert surface with the resulting friction. However, several variables must be tuned to efficiently “weld” the part: amplitude, feed rate, pressure and weld time.

Amorphous plastics are the most forgiving with this method given the broad softening properties of the glass transition, but semi-crystalline thermoplastics require more energy to cross its melting temperature. On the other hand, heat-staking machines directly conduct heat through the insert tuning only the temperature to 50°F (or 20°C) above the melting temperature of a semi-crystalline thermoplastic. This quickly melts the material without burning it, but amorphous plastics require more trial and error to optimize the install temperature. Thermosets do not accommodate either of these installation methods.

Animation of the heat staking installation process for threaded inserts.

Application

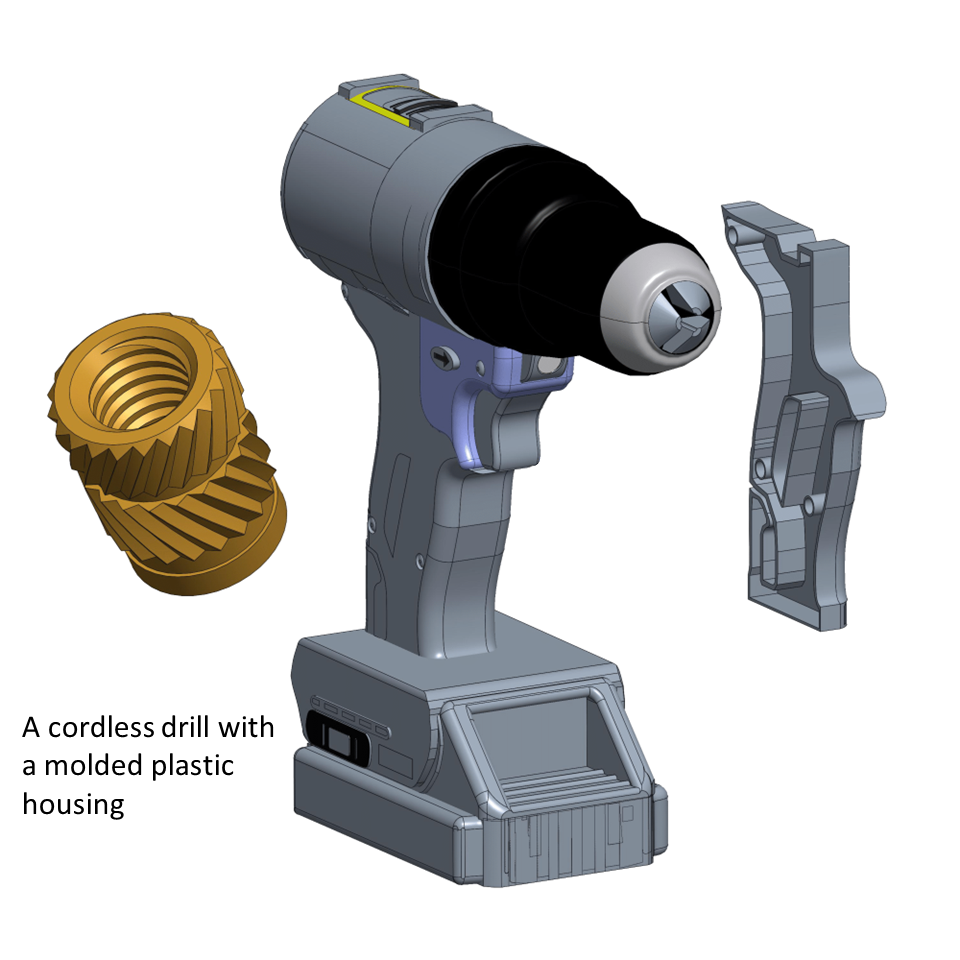

Heavy-duty power tools like a cordless drill must be both sturdy enough to withstand the dirt and wear and tear associated with a construction site while also being light enough to comfortably use for the entirety of a workday. This is accomplished using an amorphous, thermoplastic housing with threaded inserts to securely seal the electronics of the drill from its environment. The amorphous plastic is light and extremely impact resistant as opposed to semi-crystalline thermoplastics or thermosets, and the glass transition allows for ultrasonic inserts to be installed faster and with less energy into the molded bosses than heat staking inserts.

Heat staking inserts can provide strong threads in molded plastic housings for heavy-duty tools and equipment.

Alternative Solutions

Given the complex shapes of handheld power drills, molded-in inserts might make mass production faster, especially for higher volumes, and would provide the best performance. However, for a smaller, less established brand that doesn’t have access to the tooling and equipment, ultrasonic or heat-staking inserts could serve as a more economical means by which to put strong threads in plastic enclosures. Fasteners could be foregone altogether by designing clips into the housing but would greatly complicate the molding process and in turn increase production costs.

Relevant products from PEM:

Explore a range of ultrasonic and heat-staking inserts in our Product Finder:

To learn more about PEM ultrasonic or heat-staking inserts performance, visit the SI® Catalog.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736