Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

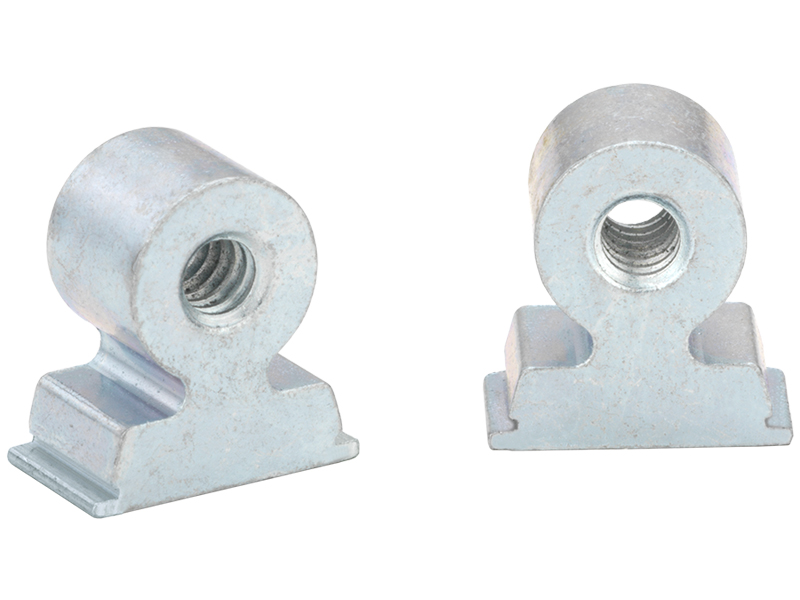

Right Angle Fasteners

Attachment Technologies

Overview

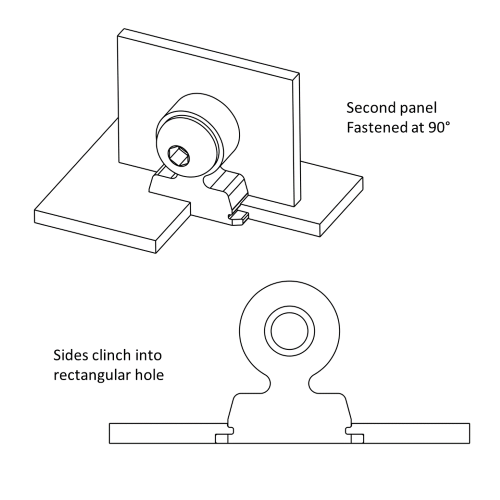

Most fasteners deal exclusively with axial retention, whether it’s standoffs, clinch nuts, tack pins or threaded inserts. Right angle fasteners are one of the few that break this convention, with threads that are turned 90 degrees from the direction of the clinching feature. A rectangular, side-clinching base supports a circular top that holds the threads, allowing for panels to be connected to each other at a right angle. Alternatively, the hole can be left unthreaded with an open wedge in the top to accept self-tapping screws or tapping for a specific thread size. Having two-fold symmetry like the cable tie mount ensures that their installation follows the direction of the rectangular, punched holes in a panel, but also requires expensive manufacturing like sintering or metal injection molding (MIM).

Application

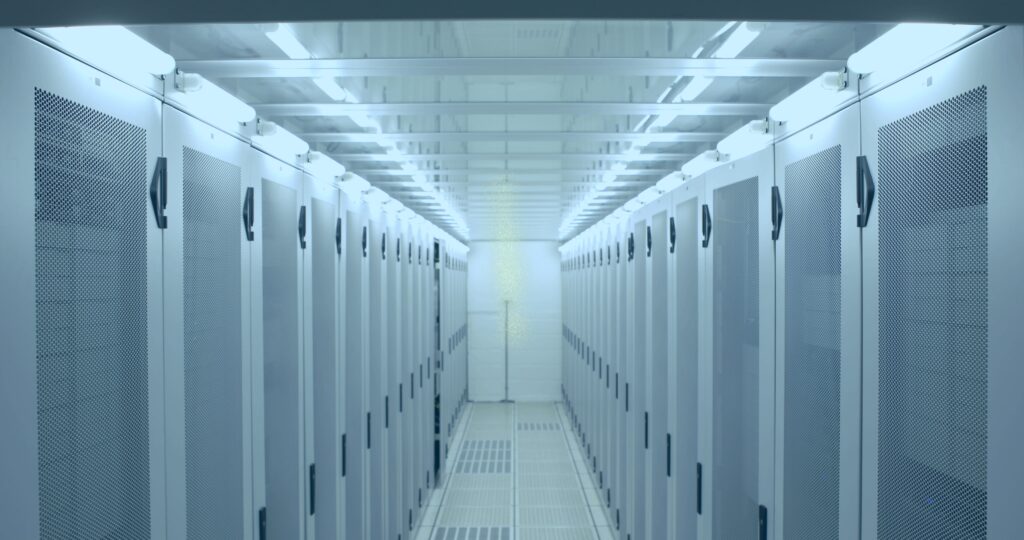

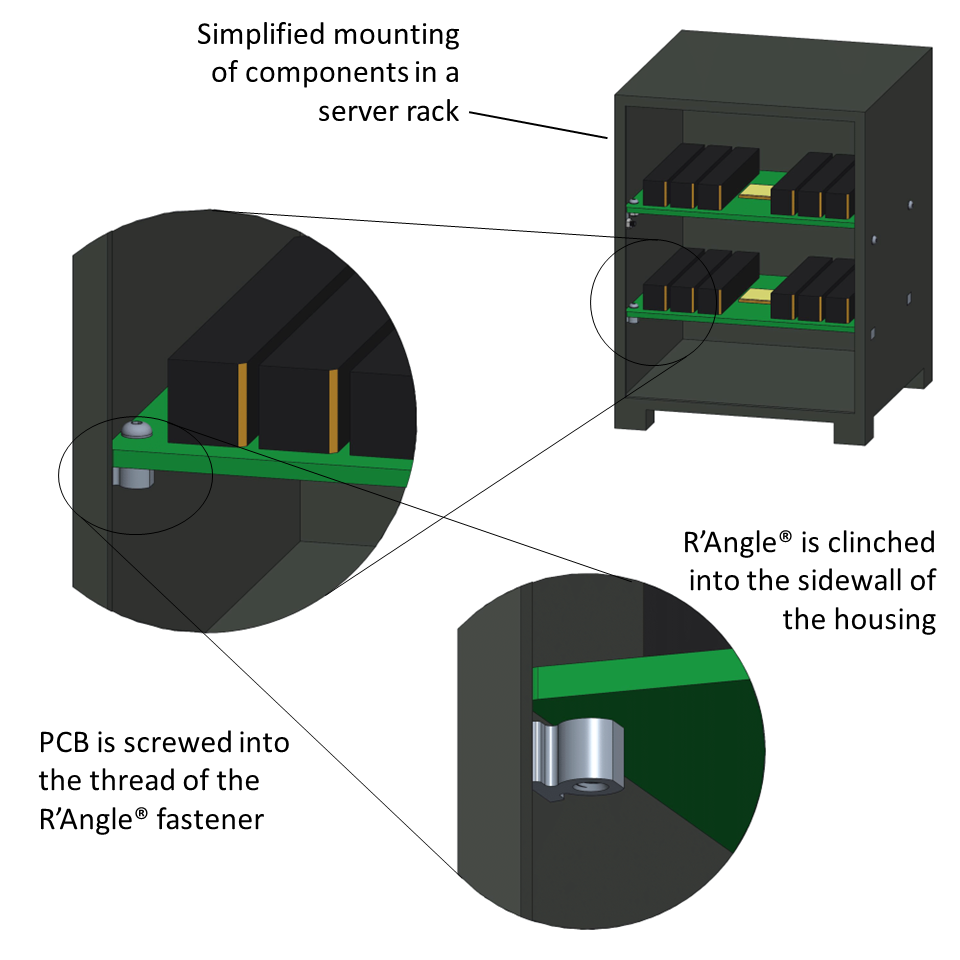

Right angle fasteners are particularly useful in connecting two dissimilar materials, like PCBs and the metal housing that conceals them. Small server racks might see an array of PCBs and electrical components with faceplates fastened directly to their edge. This is especially simple with right angle fasteners, which can clinch into the metal faceplate panel while accepting a screw that threads through the PCB.

A PCB component mounted to the walls of a small server rack.

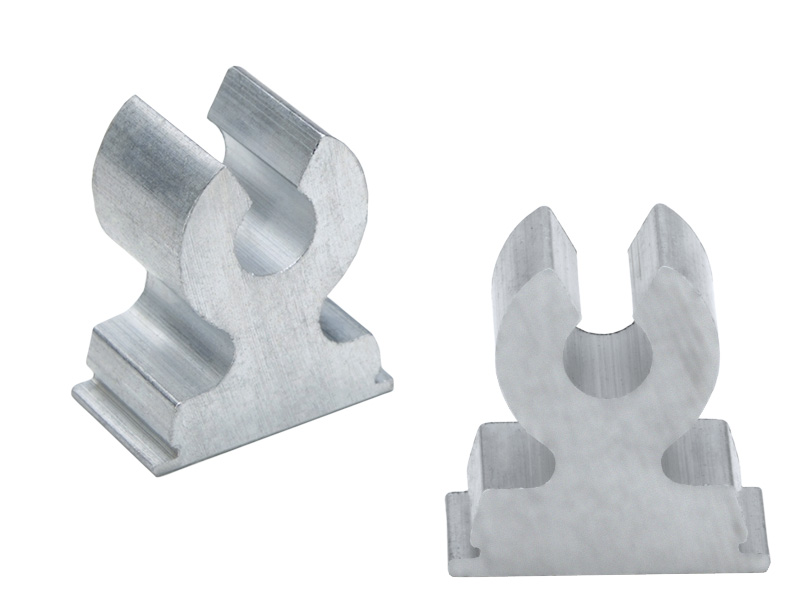

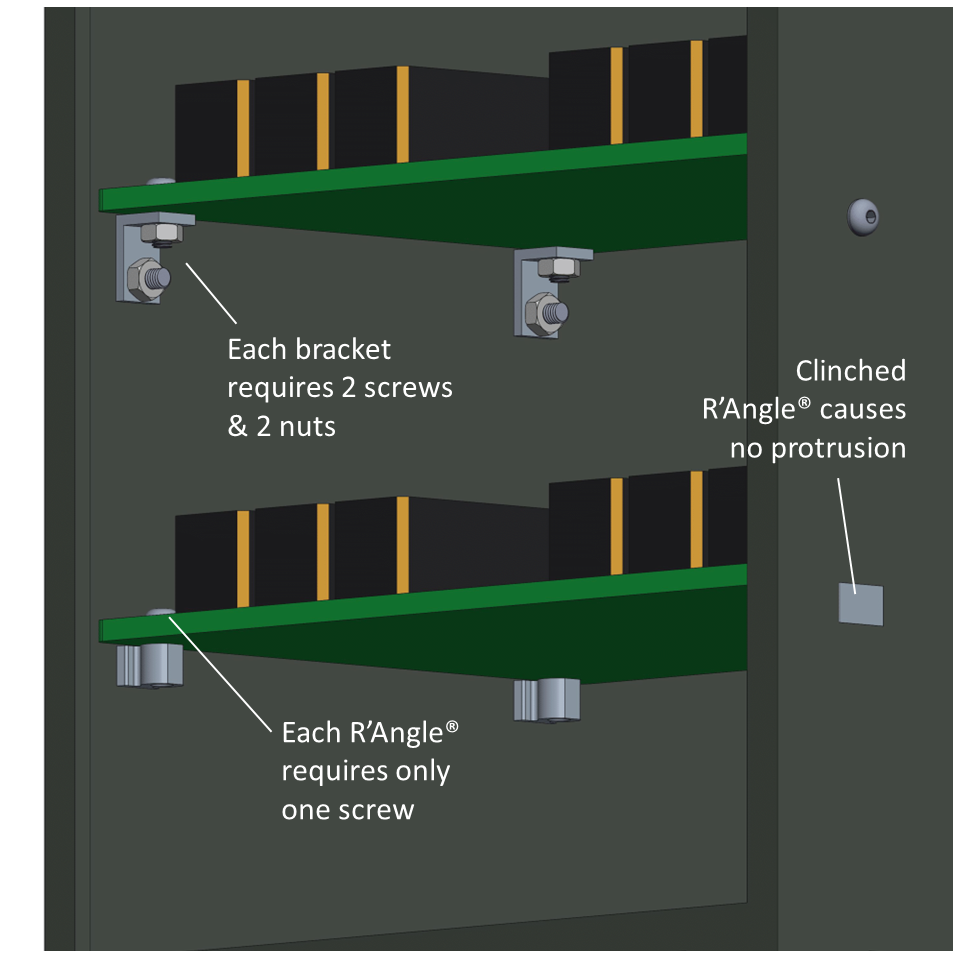

Comparison of loose parts between angle brackets and R'Angle® fasteners.

Alternative Solutions

The standard solution to a right-angle joint is a square bracket, which provides a 90° bent strip of metal with a hole in either end to screw the two panels together. While this circumvents the install machines required for expensive clinching parts, this requires more hands, more parts, and more time to install. Square brackets might be useful for joining dissimilar materials like plastics or PCBs that can’t be clinched into, but the surface mounted (SMT) variety of the right-angle fastener can address some of these situations.

Common Attachment Technologies

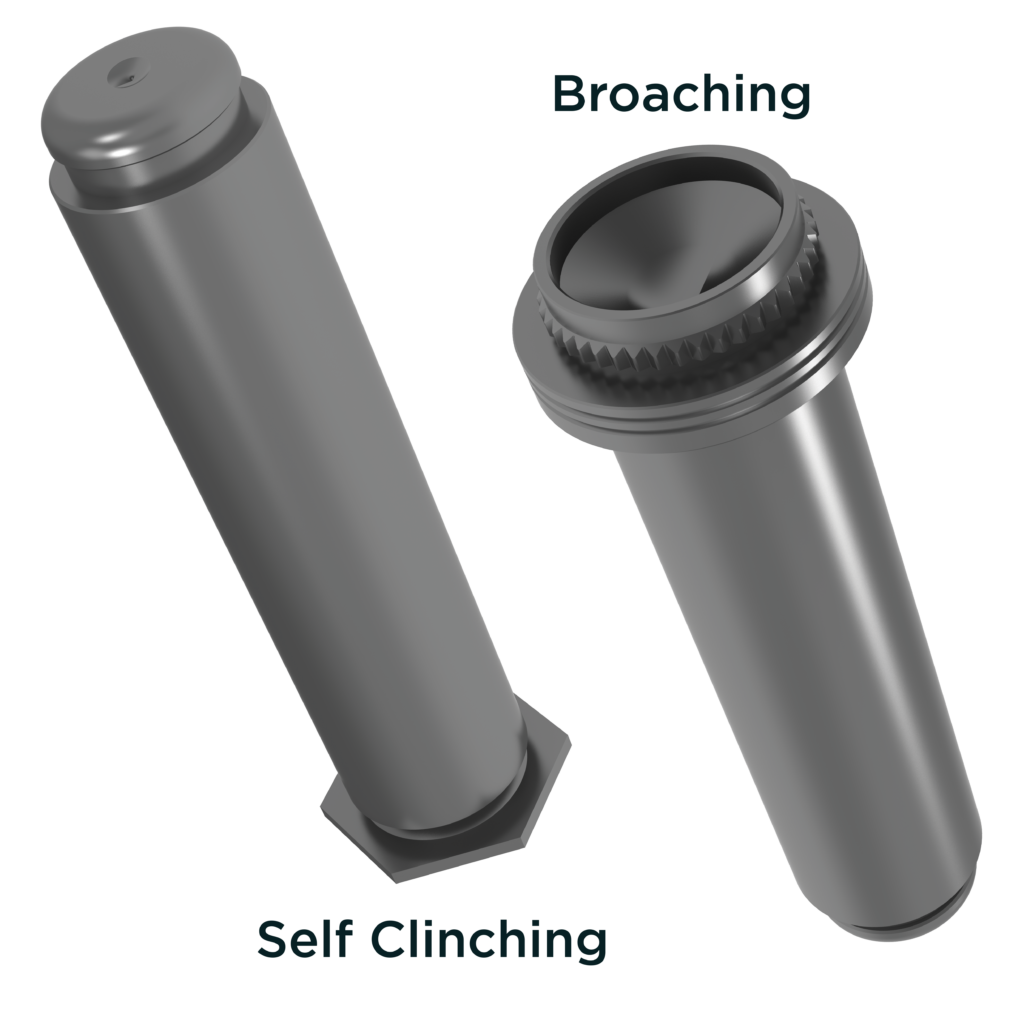

The self-clinching right angle fastener is commonly used when screwing a plastic or metal cover panel onto a metal housing. However, some applications see the mounting of electrical components to a PCB using SMT right angle fasteners, which use reflowed solder pads or paste to adhere a right angle fastener to the circuit board.

Relevant products from PEM:

Explore a variety of right angle fasteners in our Product Finder:

To learn more about PEM R'Angle® products and installation guidelines, visit the RA Datasheet.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736