Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

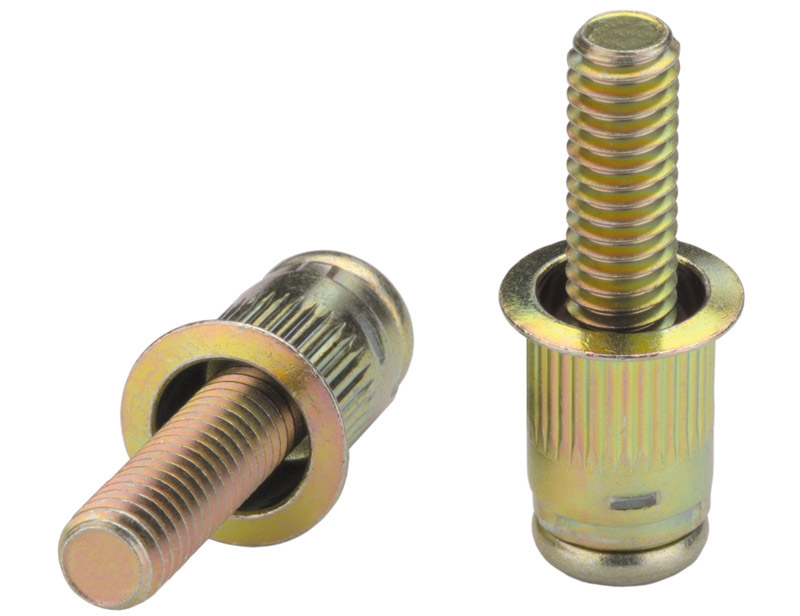

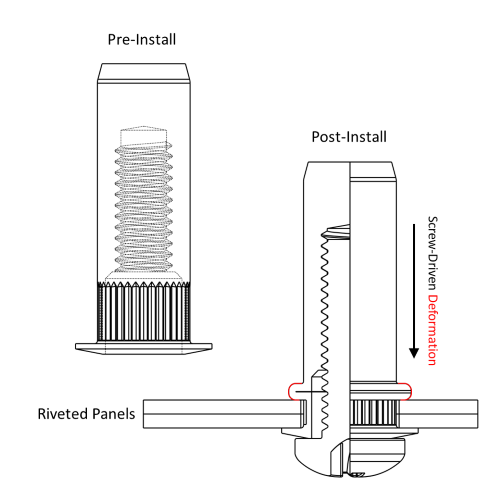

Rivet nuts or blind rivet nuts somewhat resemble blind or through-hole standoffs in their general form, but they’re designed to deform or collapse in a controlled manner upon tightening with a mating external thread. This is achieved by counterboring the head or flange side of the nut for some length, creating a slightly thinner wall before the regular threads towards the end of the rivet nut. This thin wall collapses on the opposite side of a panel to preload a joint with access only to the installation side.

Application

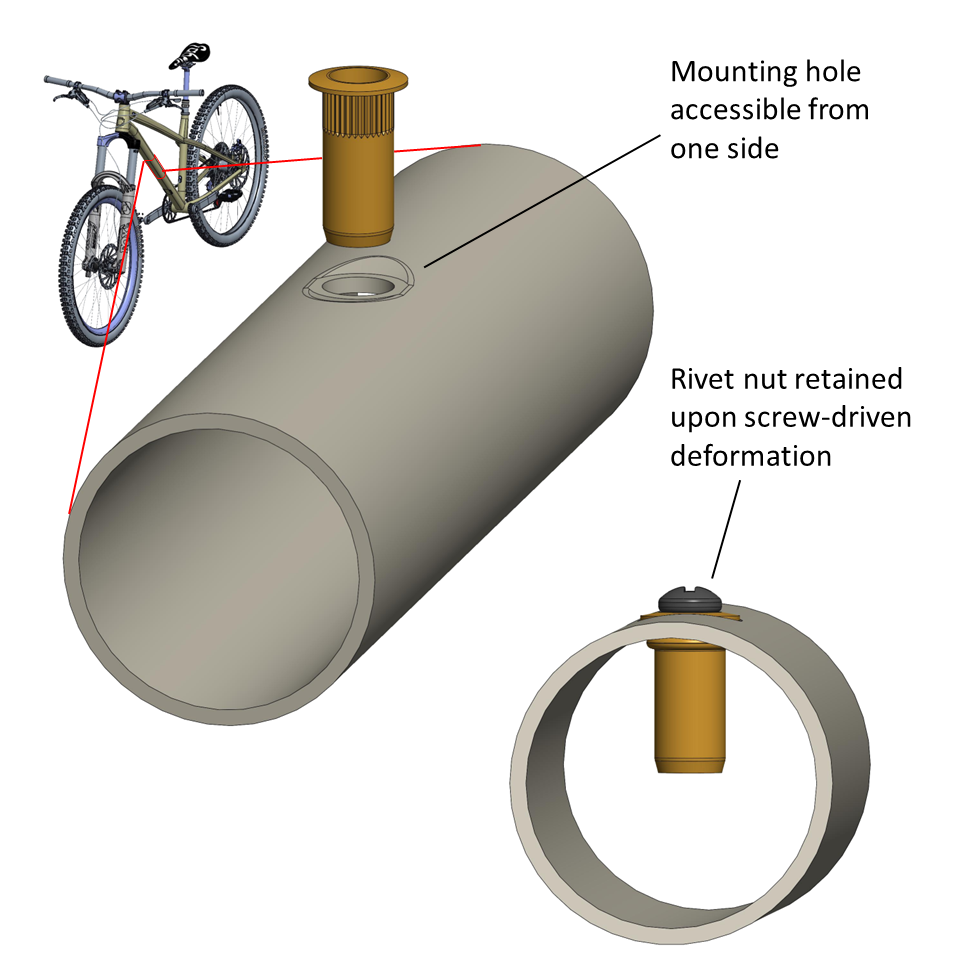

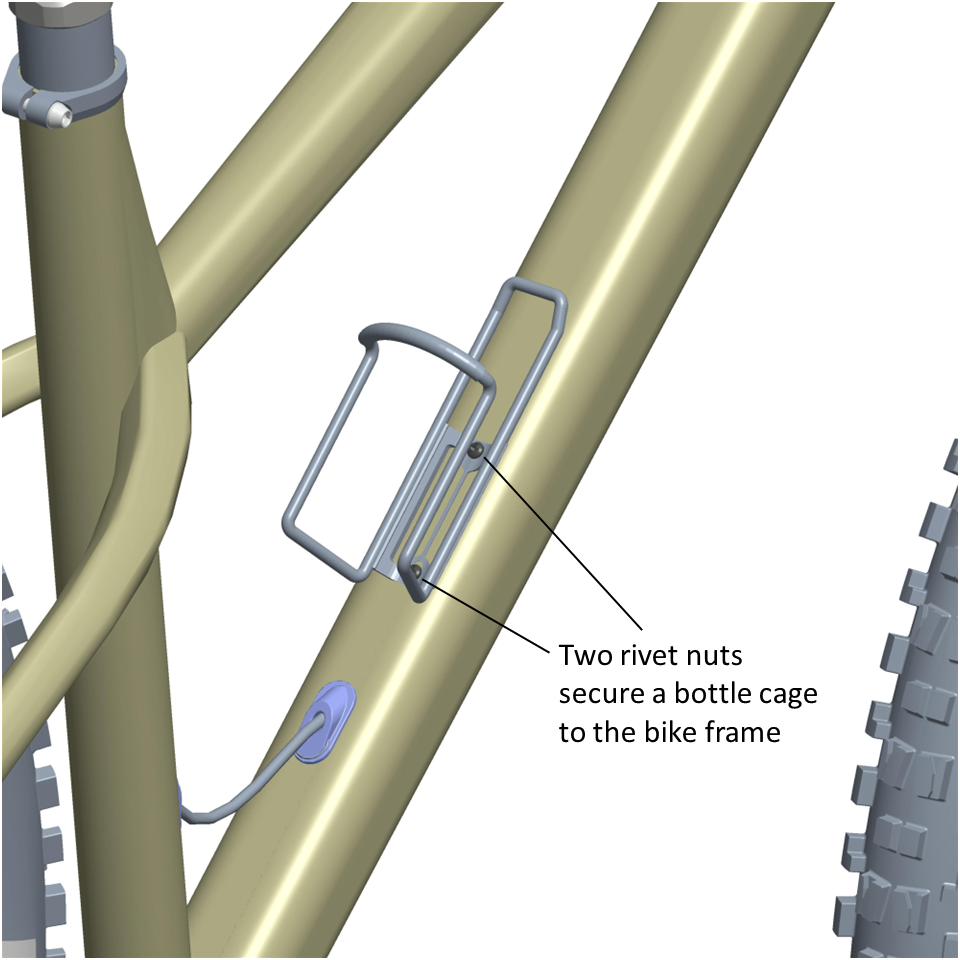

The applications in which rivet nuts truly shine are cases in which a strong, reusable thread is needed in a panel that is accessible only from one side due to the assembly. Consider a bottle cage on a bicycle. The frame of a bicycle is made from metal piping with a sealed off interior, leaving few options for attaching a variety of accessories. A small, threaded blind rivet nut requires only a single hole to be drilled in the piping which is blocked after the rivet is installed. The provided threads allow for a stock bottle cage to be securely fixed to the frame while allowing for removal if a different size is preferred.

The rivet nut uses its unique utility to mount a bottle cage to a bike frame

with access to only one side of the mounting hole.

Alternative Solutions

Without rivet nuts, both sides of the install surface need to be accessible. The next best solution might be drilling through the pipe for loose nuts and bolts, requiring more parts and complicating the assembly to securely fix the bottle cage. Without breaching the frame, brackets could be fastened around a pipe to provide a mount, but this is even more complicated and relies on friction to secure the accessory. Despite its advantages, the rivet nut can only resist torque in a round hole with the clamping pressure between the flange and the collapsed, knurled barrel. Applications with larger components and greater forces might utilize a hex barrel rivet nut with a similarly hexagonal hole to resist free spinning, but this involves more specialized tooling to manufacture and assemble.

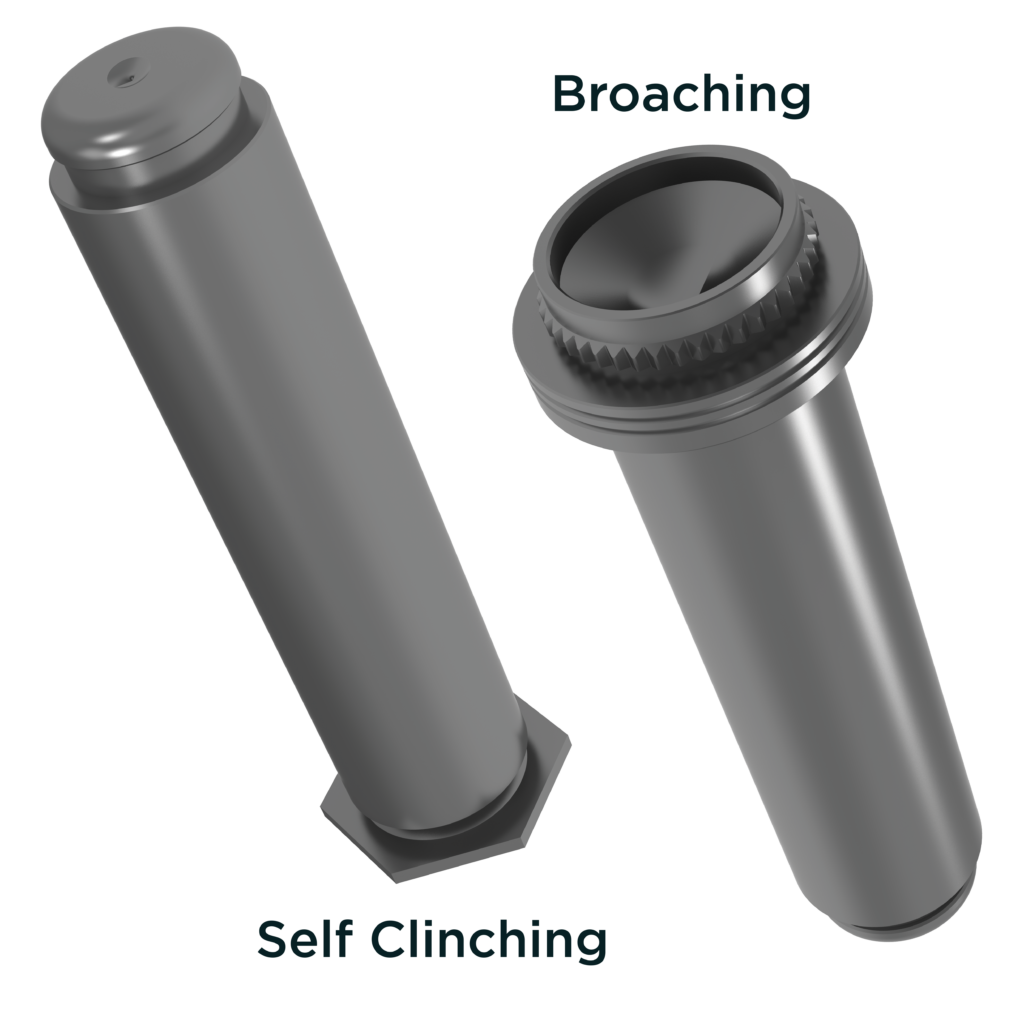

Common Attachment Technologies

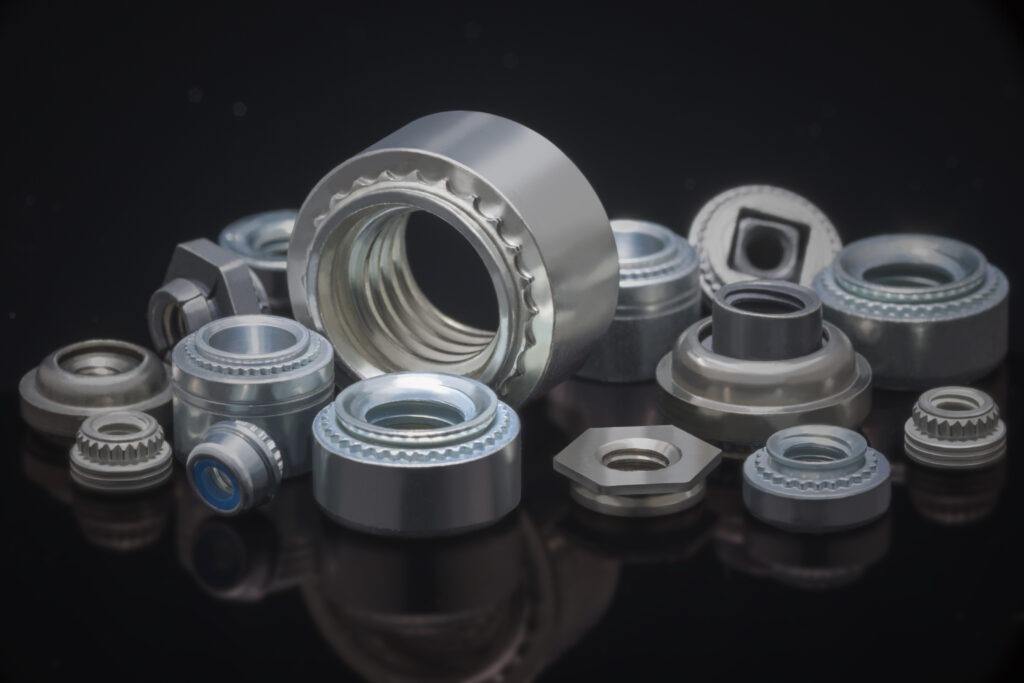

While rivet nuts have their own mechanism for attaching to a panel, they come in varieties of round and hexagonal barrels for different torque needs, blind and through-holes, and even studs to have an external thread that can be installed from one side of a panel. The countersink head rivet nut even allows for installation flush with the surface of the panel.

Relevant Products from ATLAS by PennEngineering:

Explore the wide variety of rivet nuts and studs from the ATLAS family in our Product Finder:

To learn more, visit the ATLAS® Catalog for rivet nuts and studs.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736