Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

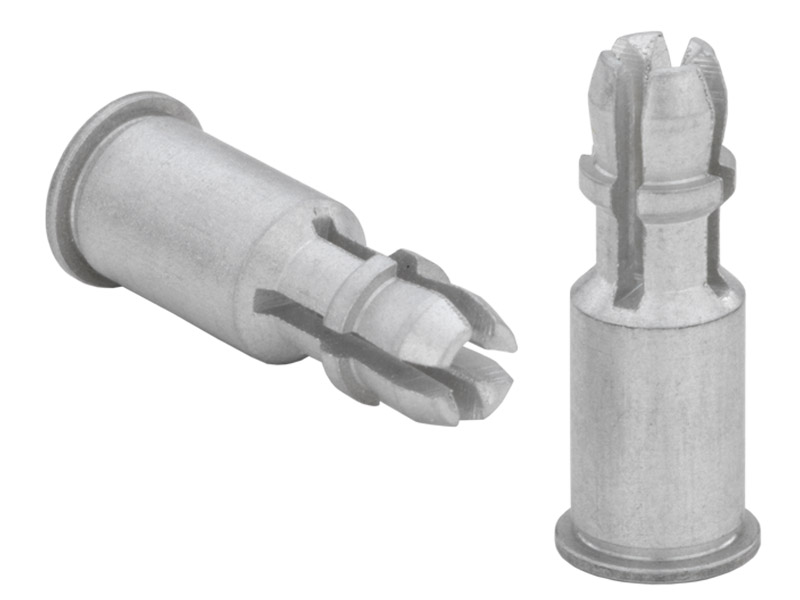

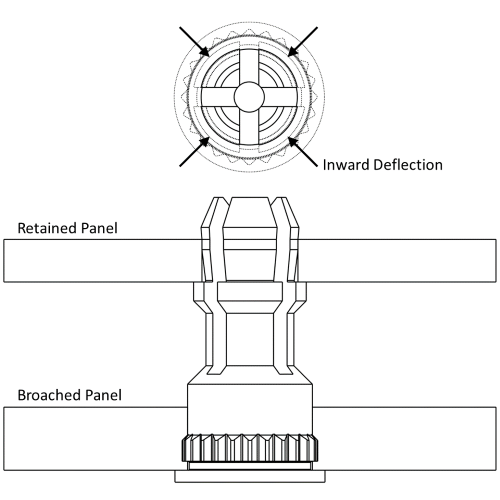

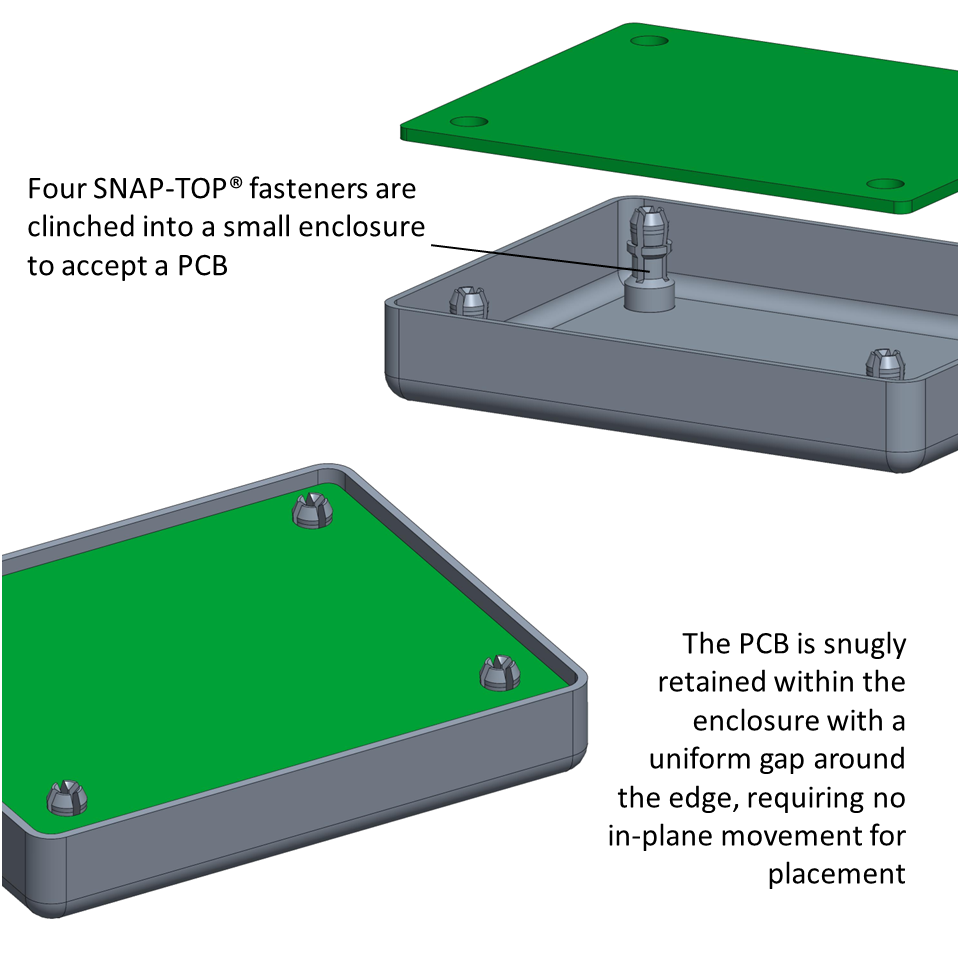

SNAP-TOP® standoffs have a unique attachment feature on the top end of the body. A spherical retaining geometry sits on a shoulder, below which the diameter slims for a short distance before returning to the barrel diameter of the opposite end of the body. Additionally, two perpendicular cuts centered along the axis travel the length of the slim diameter. This allows for the four quarters to deflect inward and creates a flexible outer diameter approaching the tip of the retainer. The opposite side of the fastener can still employ a wide variety of attachment technologies, as the SNAP-TOP® design is rotationally symmetric and doesn’t experience torque in application. This symmetry also commonly results in the use of round bar stock.

Application

The SNAP-TOP® standoff can eliminate the use of screws in panel or PC Board mounting via a vertically displaced interference fit. The holes in a PCB are machined slightly smaller than the outer diameter of the retaining geometry at the top of the fastener. With some force, pressing the PCB over the retainer causes the reduction of the outer diameter via deflection. Once the PCB passes over the widest diameter, the deflection of the quarter sections presses the board into the shoulder, retaining it.

SNAP-TOP® standoffs axially retain a second panel, allowing for more compact enclosures housing PCBs.

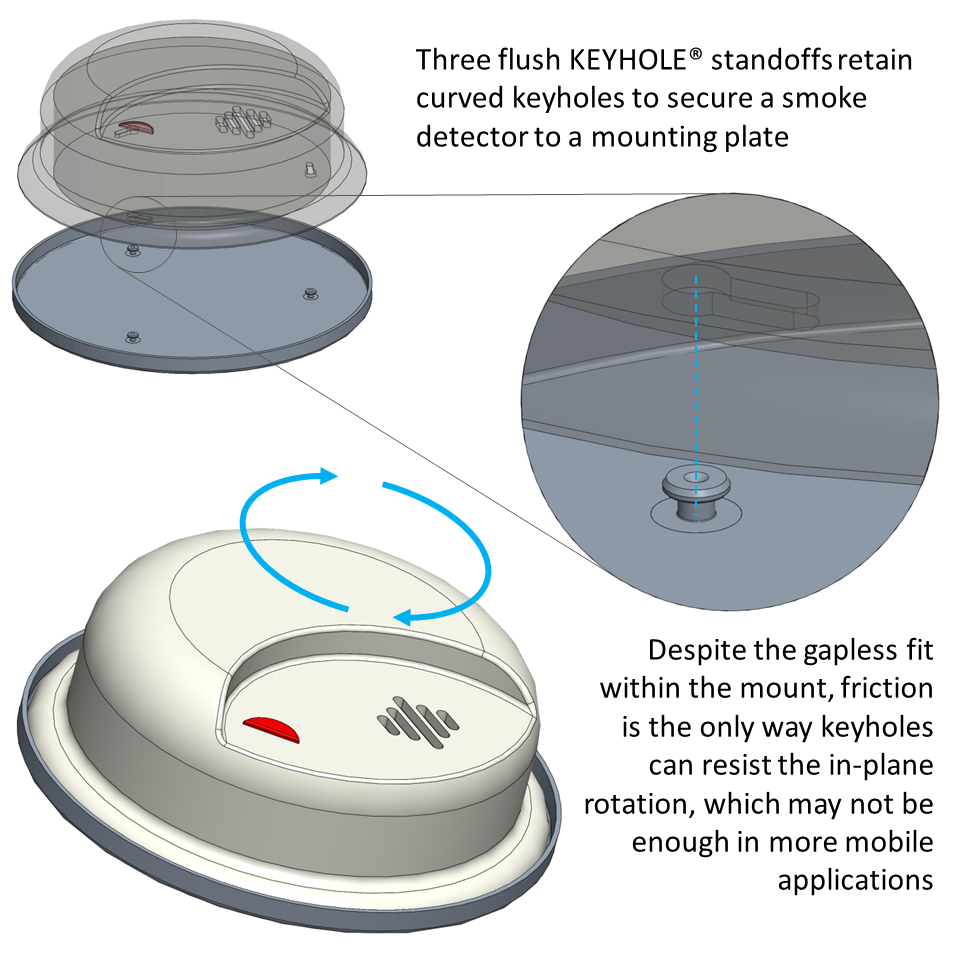

KEYHOLE® standoffs only achieve the same compact fit with in-plane rotation, which limits options for component geometry & vibration resistance.

Alternative Solutions

If the goal of an application is to eliminate loose hardware, one alternative would be a variety of KEYHOLE® standoffs. The unrestricted movement in one linear direction could be traded for a rotational displacement, like a smoke alarm fixture in a house. However, whether rotationally or linearly installed, PC Boards positioned with KEYHOLE® standoffs always require some movement in-plane with the panel or PCB. This requires more room in the assembly and can increase risk for shifting or rattling. SNAP-TOP® standoffs can circumvent this due to their vertical installation, which require only enough room to get a tool under the board to dismount it from the snapping geometry.

Common Attachment Technologies

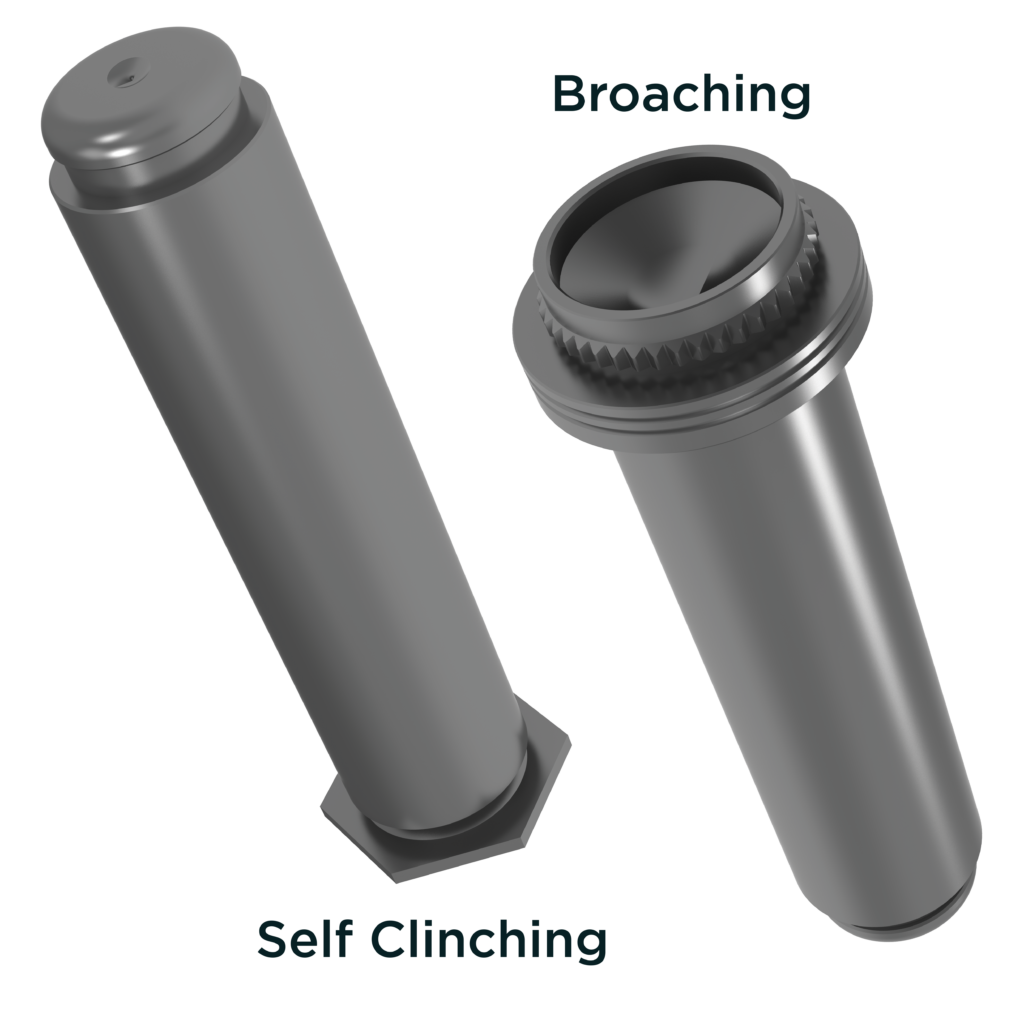

Due to their utility in PCB applications, snap-tops commonly use self clinching for panel-to-PCB joints or surface mounted technology (SMT) for PCB-to-PCB stacks. Broaching SNAP-TOP® standoffs are rare due to the force involved with assembly/disassembly. Over multiple loading cycles, they can weaken the interference fit between the broaching geometry and the PCB.

Relevant products from PEM:

Explore PEM brand SNAP-TOP® standoffs in our Product Finder:

To learn more about SNAP-TOP® standoffs, visit the SSA Datasheet.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736