Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

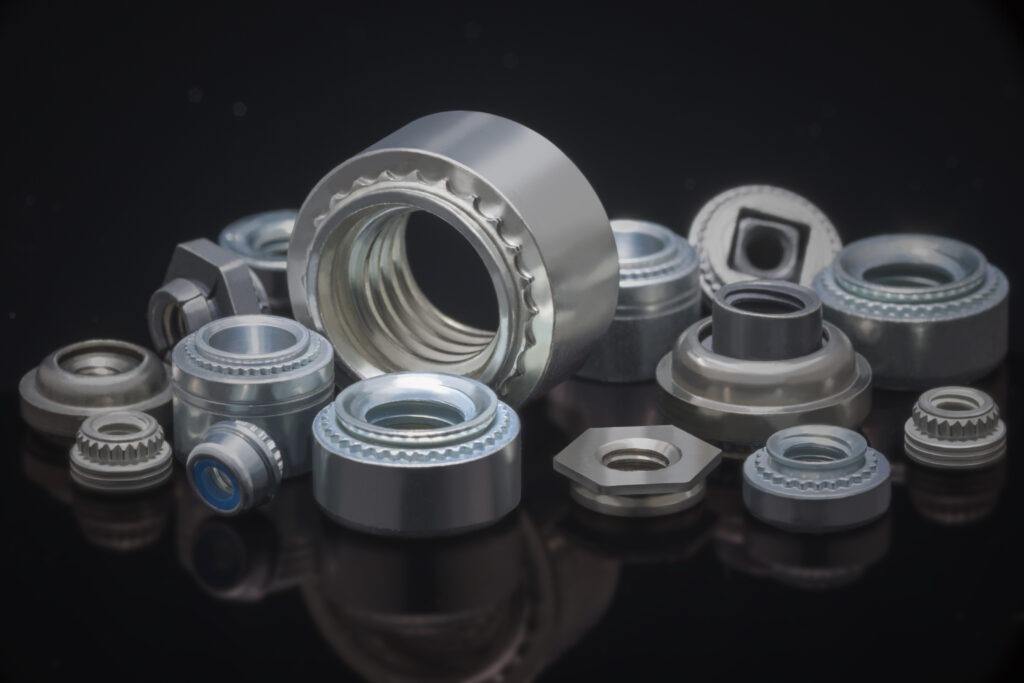

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

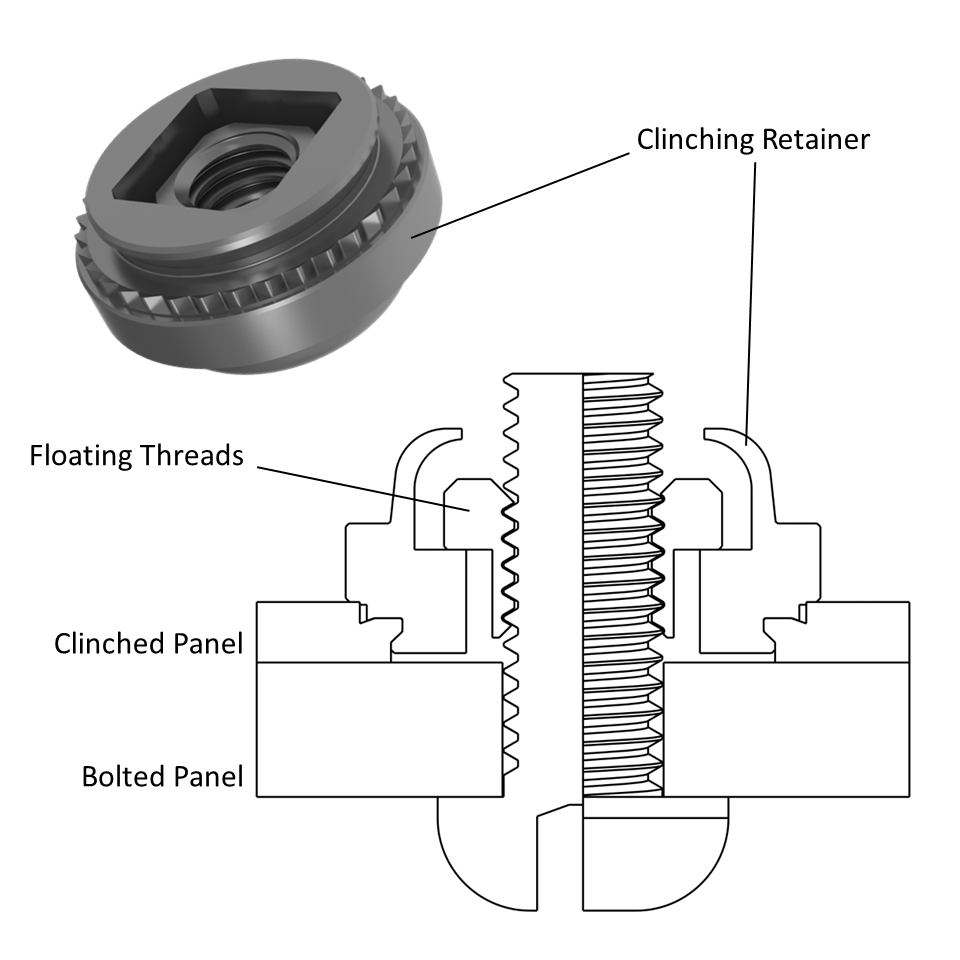

Also known as a cage nut or captive nut, a floating clinch nut typically has a square, threaded nut enclosed in a retainer which is then attached to a panel. The inner walls of the retainer are slightly larger than the square nut, allowing for side-to-side movement while still restricting rotation. There can be some variation in the form of the retained nut, such as extending its length like a standoff or partially collapsing the thread like a locking nut. However, a short nut is most common.

Application

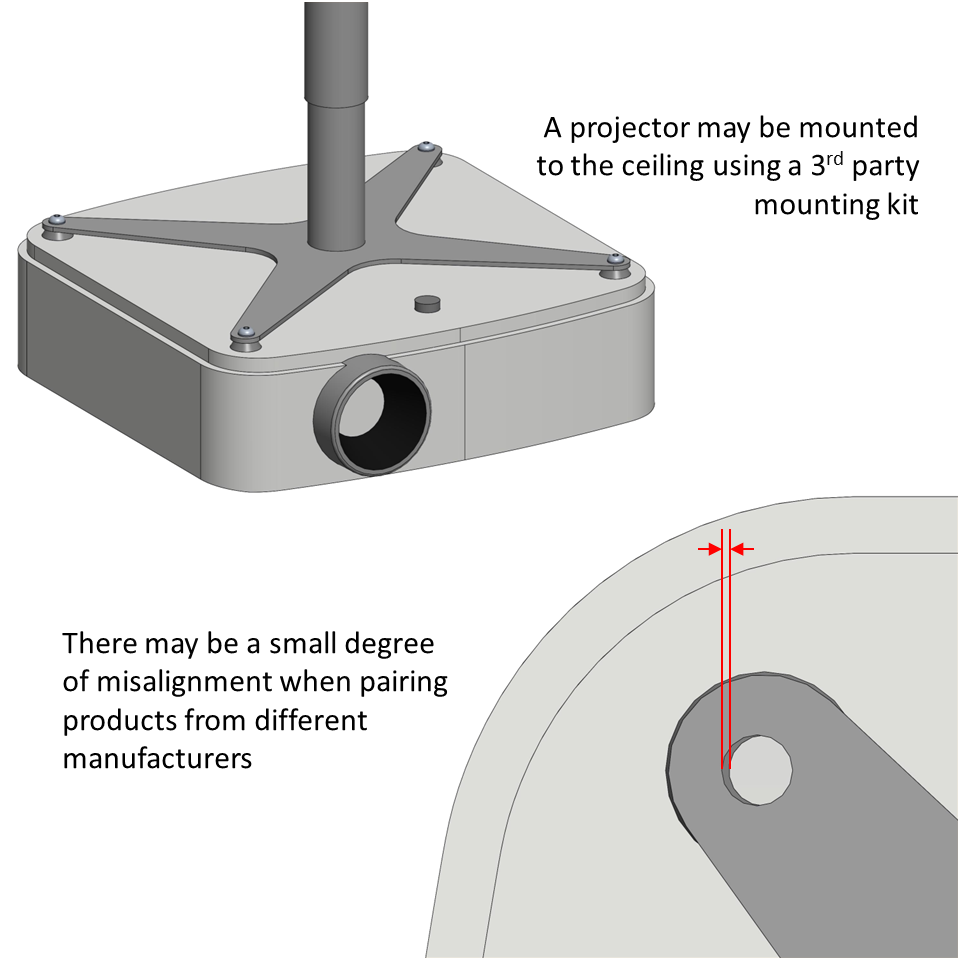

It is common for multiple products from different suppliers to be used in an application, such as a projector and the mount that holds it on a wall or ceiling. The mounting hardware may be designed with standard dimensions in mind, but this doesn’t guarantee hole alignment. To mitigate this risk, the projector manufacturer might install floating nuts to account for misalignment with a wider variety of mount brands of varying quality.

Floating nuts allow for some inconsistencies in dimensional accuracy to be circumvented, resulting in a larger

tolerance for quality issues.

Alternative Solutions

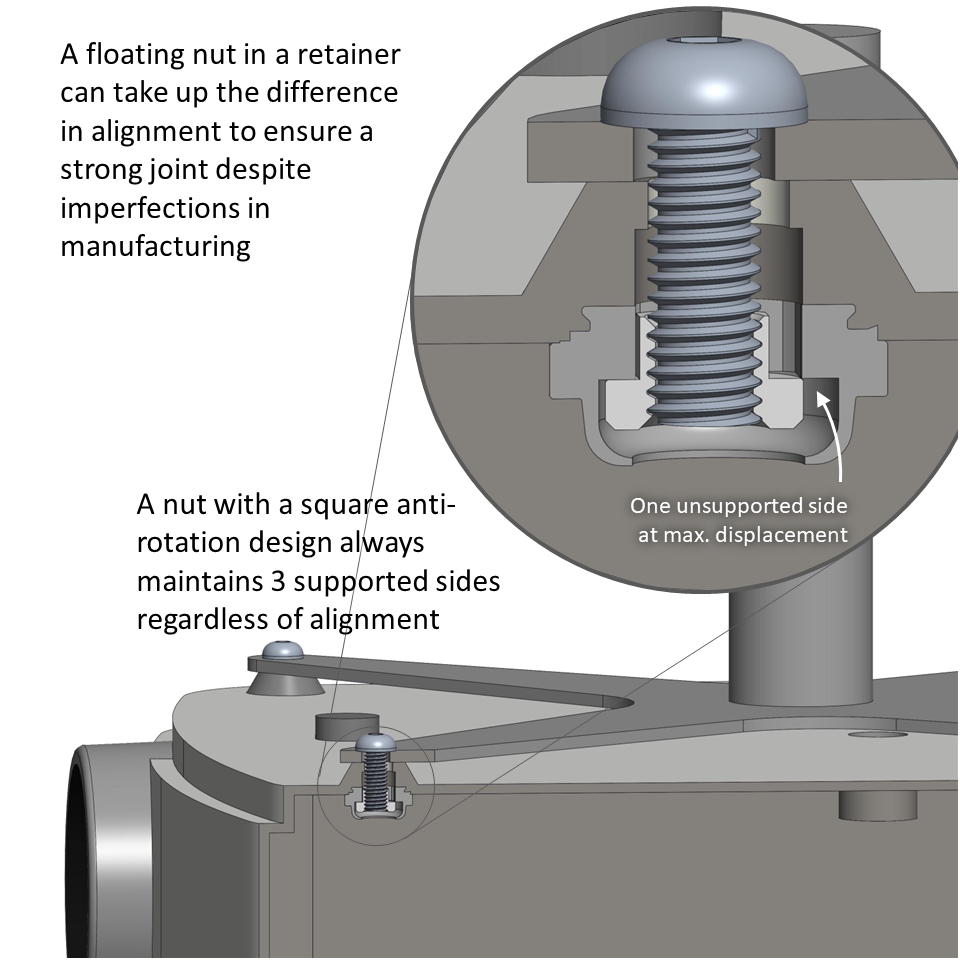

An obvious alternative to floating nuts is to use regular, threaded nuts in the projector assembly. This reduces the number of parts as well as the tolerance for misalignment. Another solution could be to use undersized hardware along with a broad washer to accept misaligned holes. This, however, increases the number of parts which are loose instead of captivated. A floating nut accounts for a degree of misalignment while also retaining any otherwise loose hardware. The tradeoff is the increased size required for the retainer in an assembly, and the increased cost of a multicomponent part.

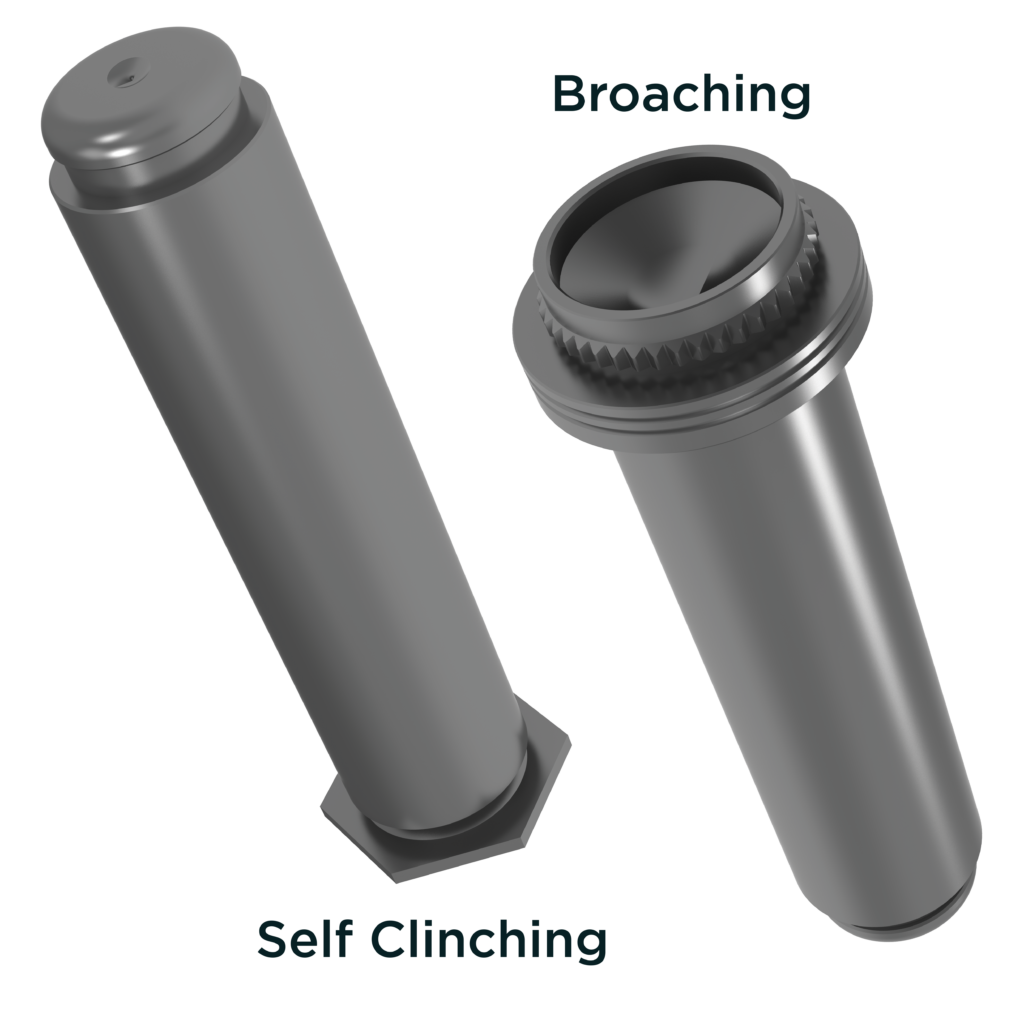

Common Attachment Technologies

Most floating nut applications involve fastening with products from other manufactures rather than internally designed assemblies, which is why surface mount (SMT) or broaching floating nuts for PCBs are rare. Most floating nut retainers feature a self clinching attachment feature to install securely into metal panels.

Relevant Products from PEM:

Explore a variety of floating nuts in our Product Finder:

To learn more about floating nuts in our catalogue, visit the ALA Datasheet.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736