Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

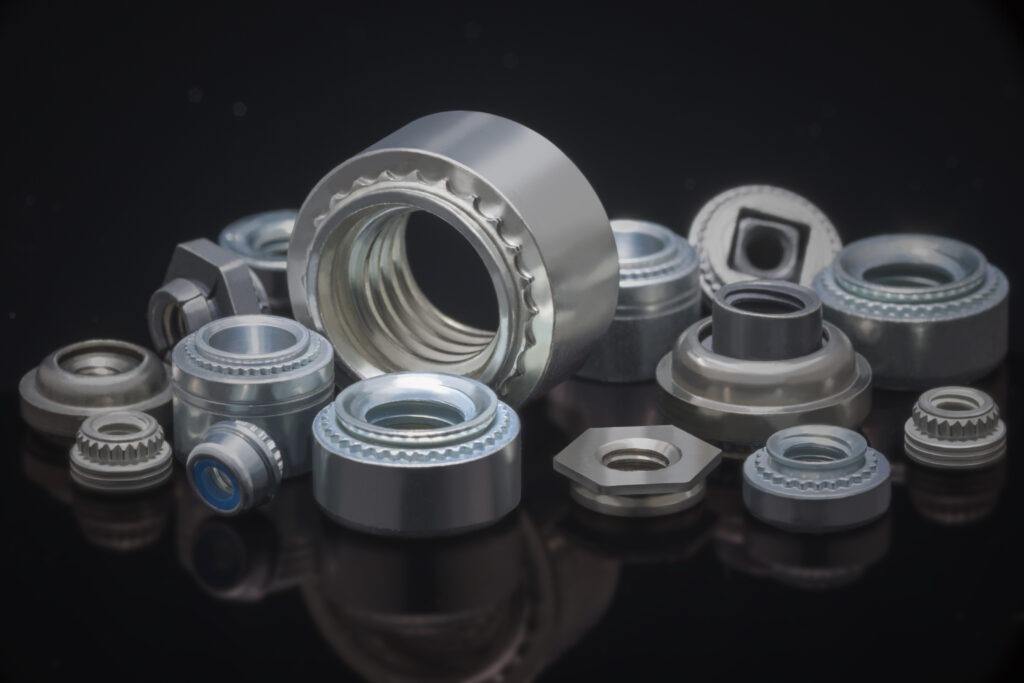

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

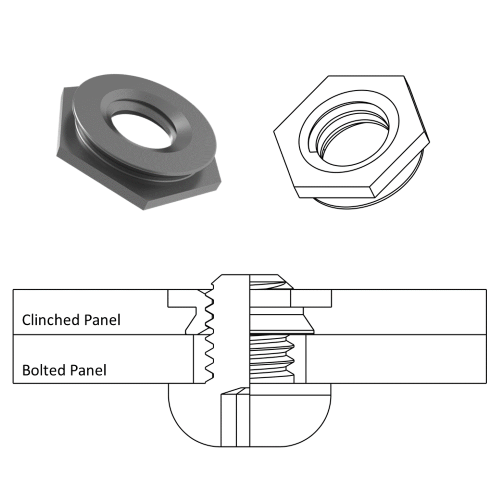

Flush nuts or flush mount nuts have one specific feature that separates them from general through-hole nuts and is dependent on the application. The overall length (or height) of a flush nut is meant to match the thickness of the panel into which it’s installed.

Application

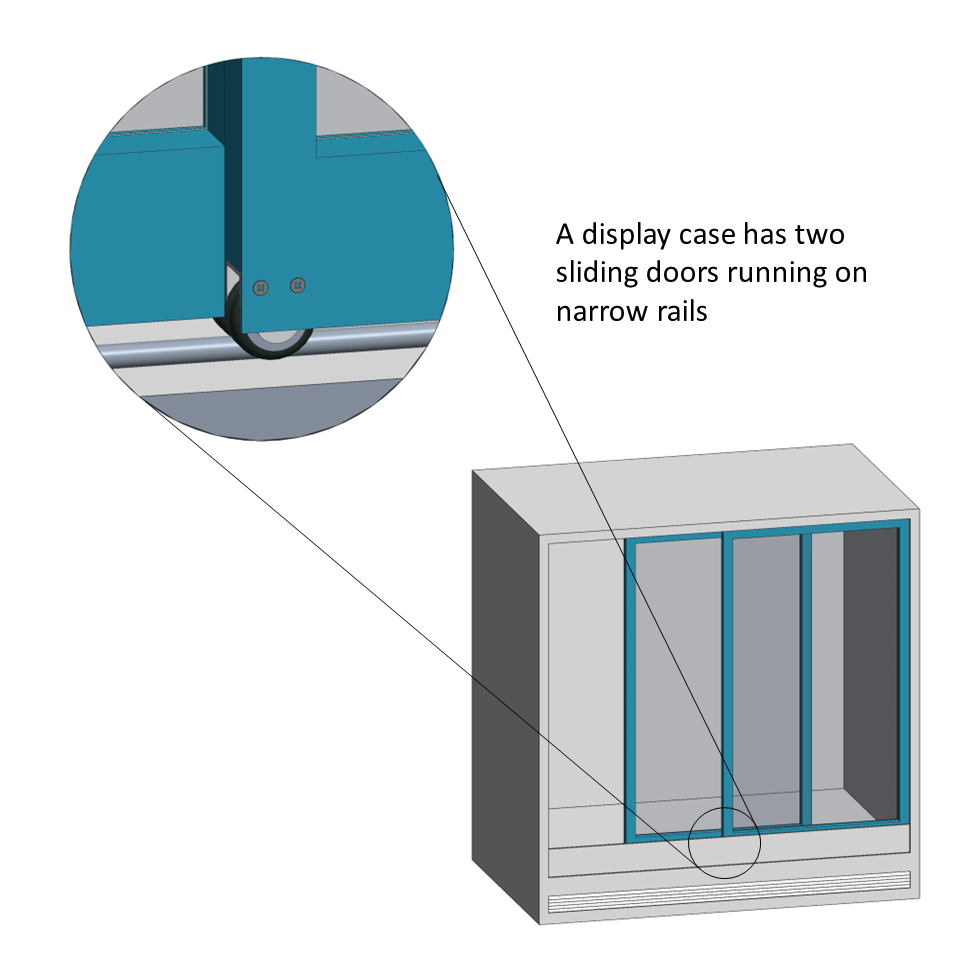

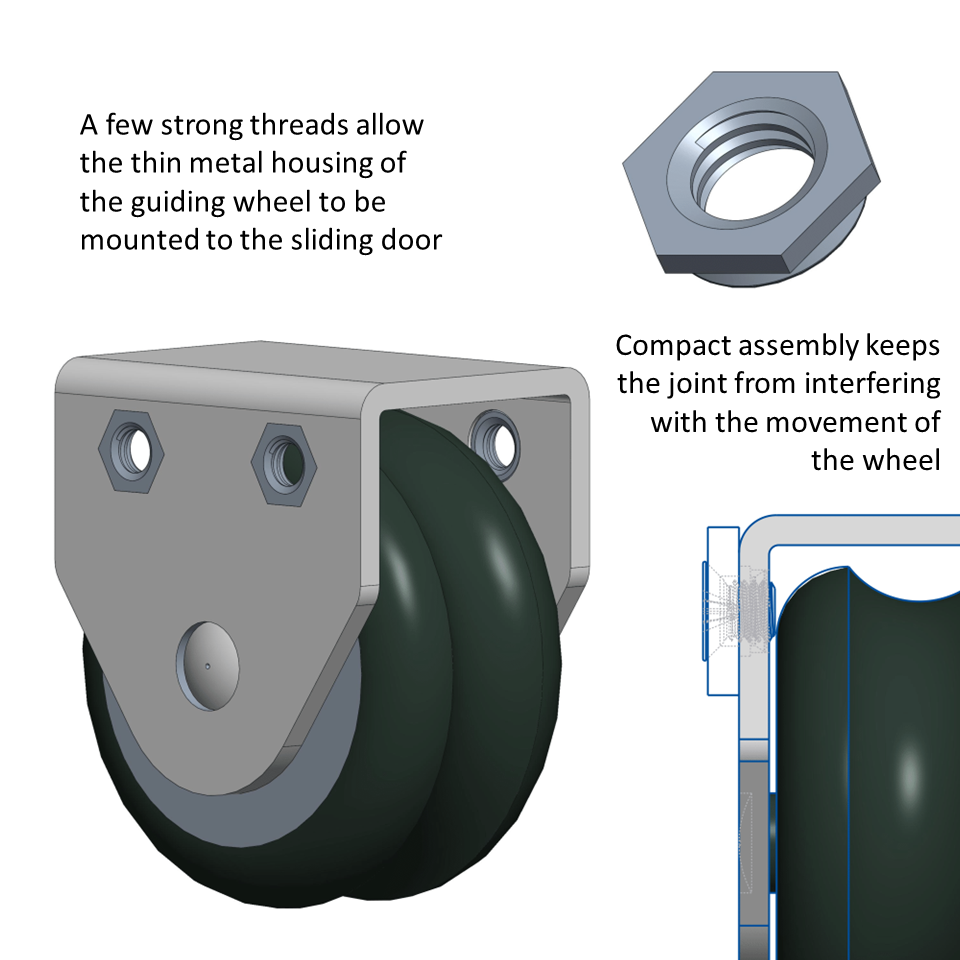

This thin nut doesn’t provide many full threads to screw into, but the threads it does provide are far stronger than if the panel were to be directly tapped. Some larger sliding doors for display cases ride on wheel assemblies that need to fit within a flat profile to minimize the thickness of the door as well as the size of the entire case. A simple rectangular housing of sheet metal is bent around a wheel, and flush nuts allow for this thin panel to have threads strong enough to secure the wheel to the frame of the door. Different applications can use different nuts with more threads to improve strength and durability when they don’t need to be flush with both sides of a panel.

This display case shows the utility of a flush nut when the application

calls for compact assemblies.

Alternative Solutions

In an application with the same space limitations, there aren’t alternative solutions other than directly tapping the panel with threads. Given how few full threads can be made in a thin panel, along with the panel material being relatively soft, the risk of cross threading is high. It’s more cost-effective compared to including an additional part for stronger threads, but this may lead to quality problems down the line. For greater strength, a taller blind nut or through-hole standoff with more threads is a simple answer, but it would require a redesign of the assembly to accommodate this increase in size.

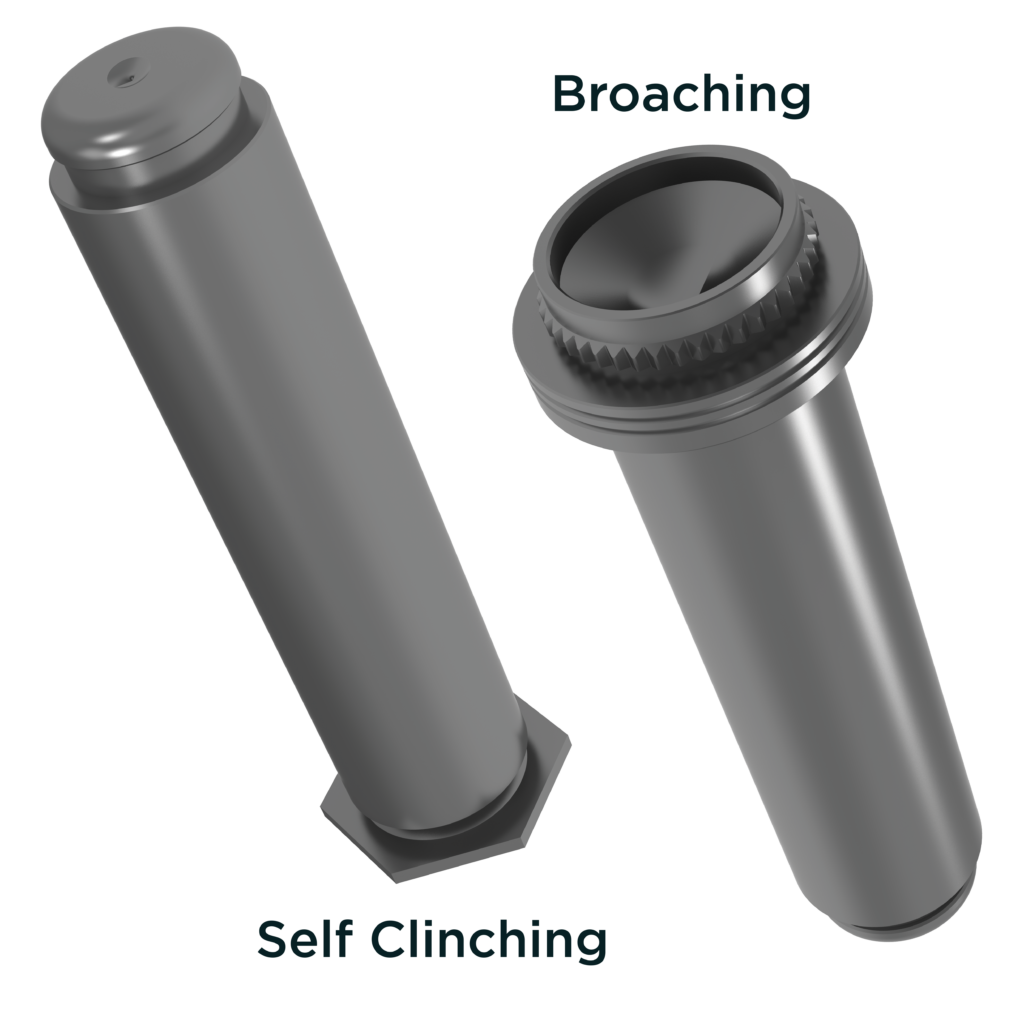

Common Attachment Technologies

Due to the amount of strength required in such a small amount of space, flush nuts are almost exclusively self-clinching fasteners. A secure interference fit broaching into a PCB requires enough surface area to maintain friction for pullout strength, and surface mounted (SMT) nuts naturally go above the surface, not meeting the flush requirements. Some rivet nuts can be "flush mounted" given the mounting hole has a countersink prior to install, but still go beyond the thickness of the panel.

Relevant Products from PEM:

See sizes and material varieties of flush nuts in our Product Finder:

To learn more, visit the F Datasheet for self-clinching flush nuts.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736