Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

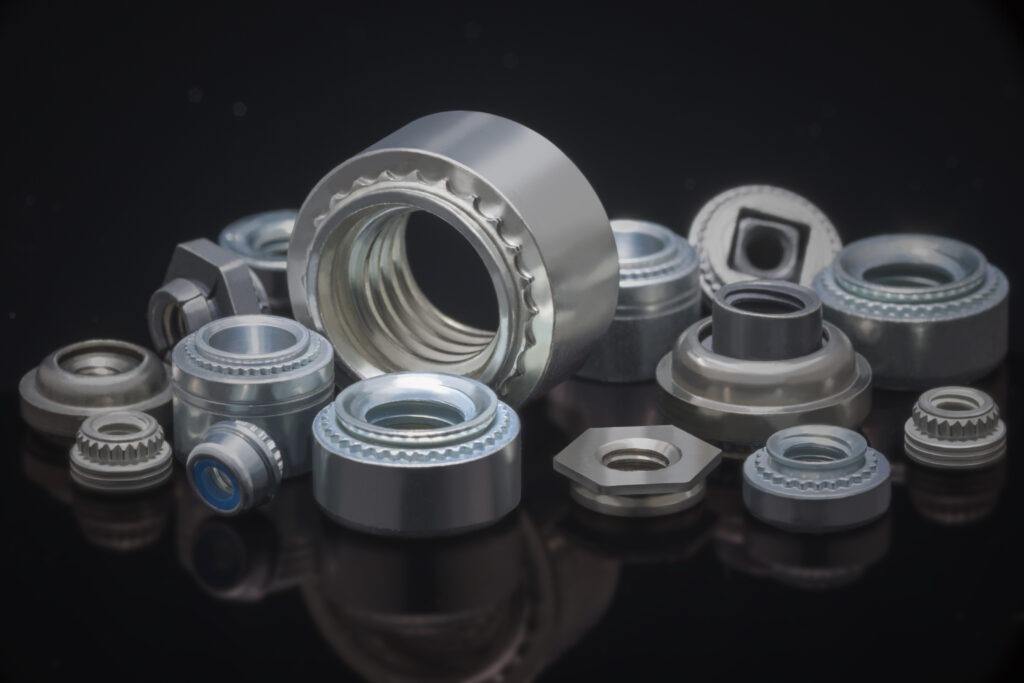

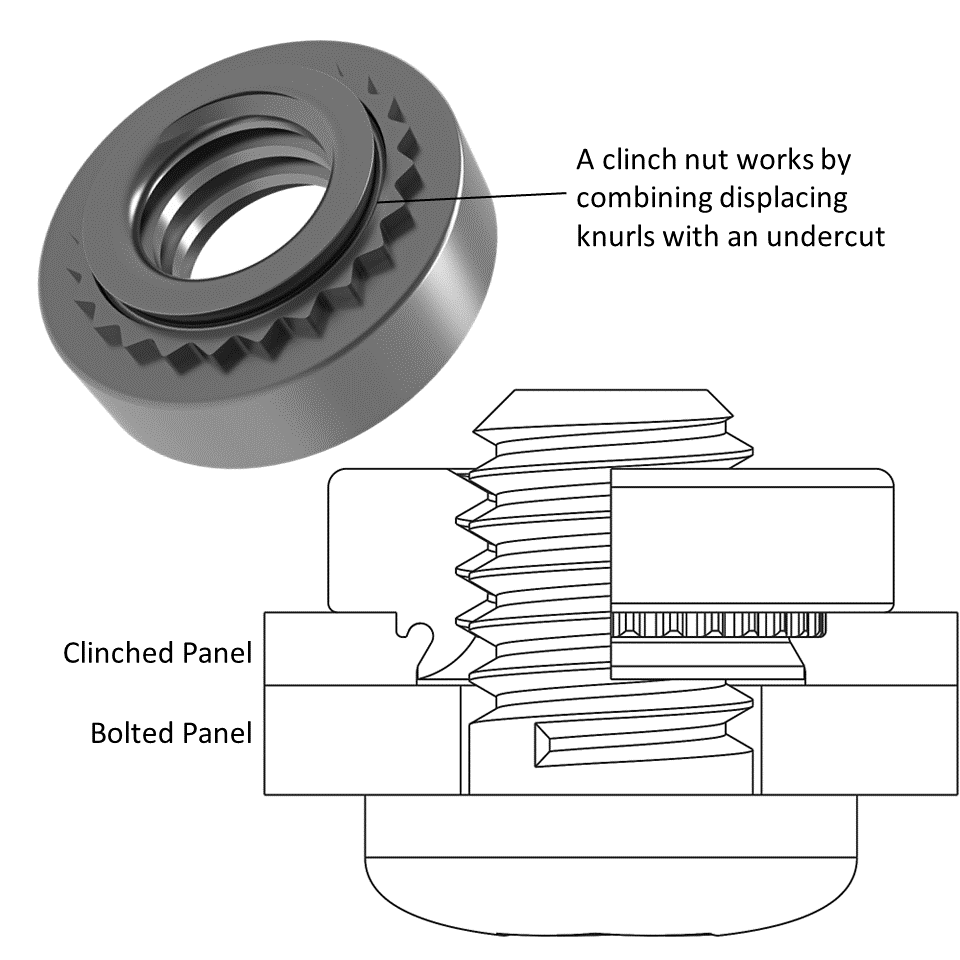

While the category of “nuts” can involve an almost limitless variety of fasteners, the manufacturing industry makes extensive use of clinch nuts. A clinch nut (also known as a press-in nut, captive nut, self-clinching nut or S-nut) typically consists of a round body rather than the hex geometry commonly associated with loose nuts. The most important feature, however, is the displacement knurl and undercut on the bottom face of the fastener. When the nut material is harder than the panel of the application, self-clinching nuts can retain themselves in a metal panel by deforming the panel material using the pressure required for installation.

Application

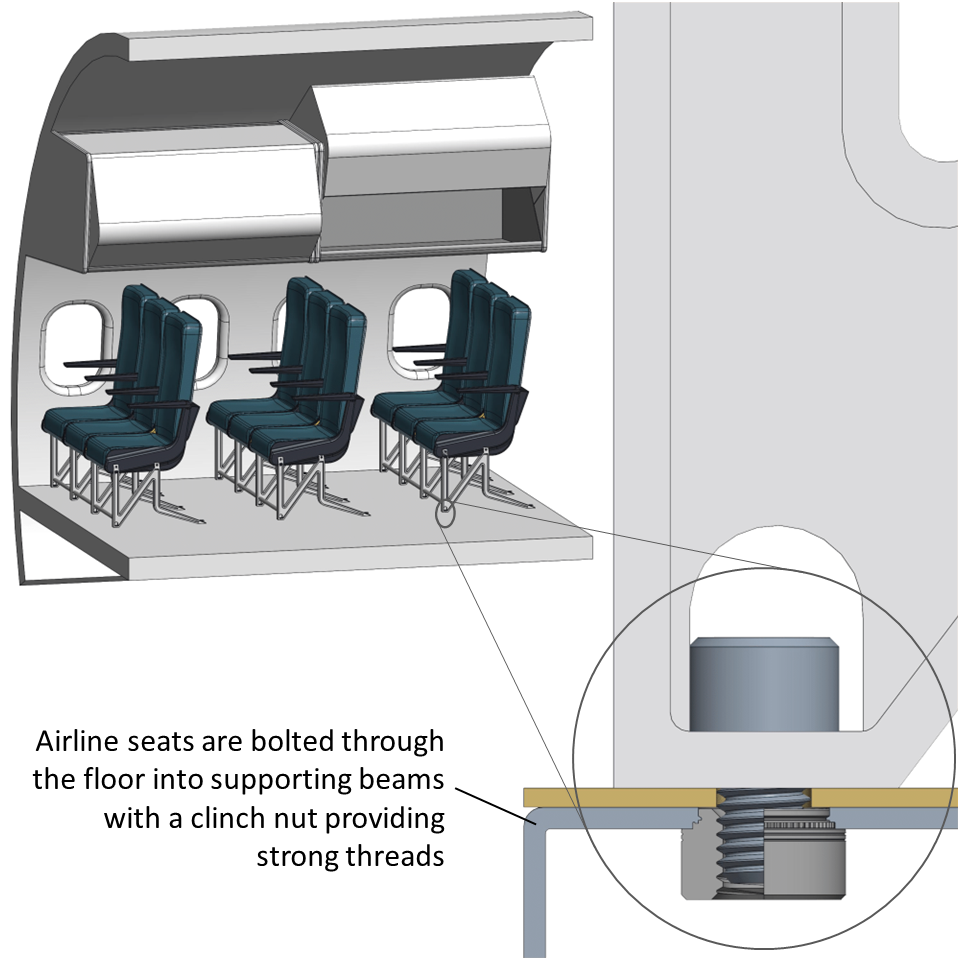

Most aerospace applications are concerned with the strength-to-weight ratio of a given assembly. Consider the rows and rows of seats on a commercial airline, which not only need to be lightweight but supportive of a person’s weight as well. The seats are bolted to the floor of the aircraft atop a skeleton of sheet metal crossbeams, which can sport high strength-to-weight, aluminum clinch nuts for reliable mounting threads. This can help minimize hardware and weight contributions, especially when multiplied over the hundreds of connections keeping all the seats in place.

Airline seats can be mounted with aluminum clinch nuts to minimize weight without sacrificing strength.

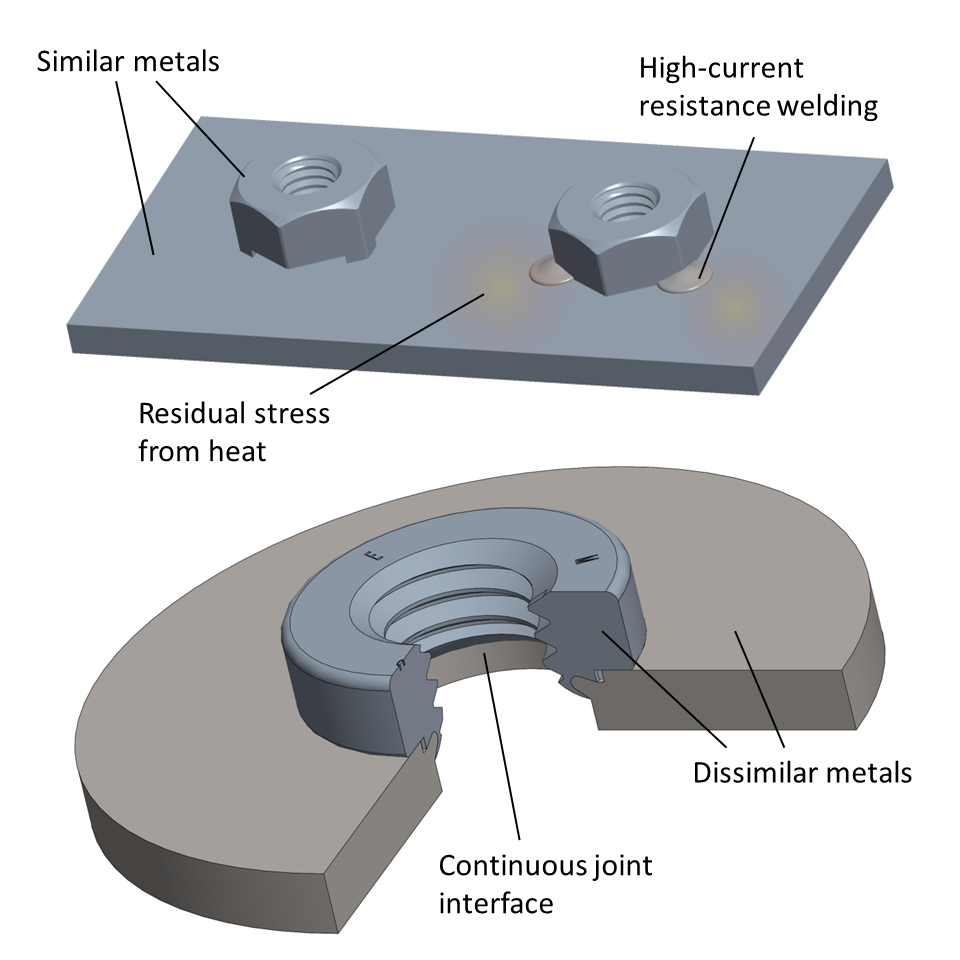

Comparison of joint properties using weld nuts and clinch nuts.

Alternative Solutions

The strongest competitor to clinch nuts in such applications are weld nuts; they require less installation equipment, use cheaper parts, and have the potential to achieve higher retention strength than their clinching counterparts. However, their largest setbacks involve the quality challenges associated with weld spatter and the requirement of similar panel and nut materials for a strong weld. Clinch nuts completely circumvent weld spatter and are compatible with a variety of dissimilar materials. For a greater discussion of clinching and welding technologies, please visit the self-clinching page.

Common Attachment Technologies

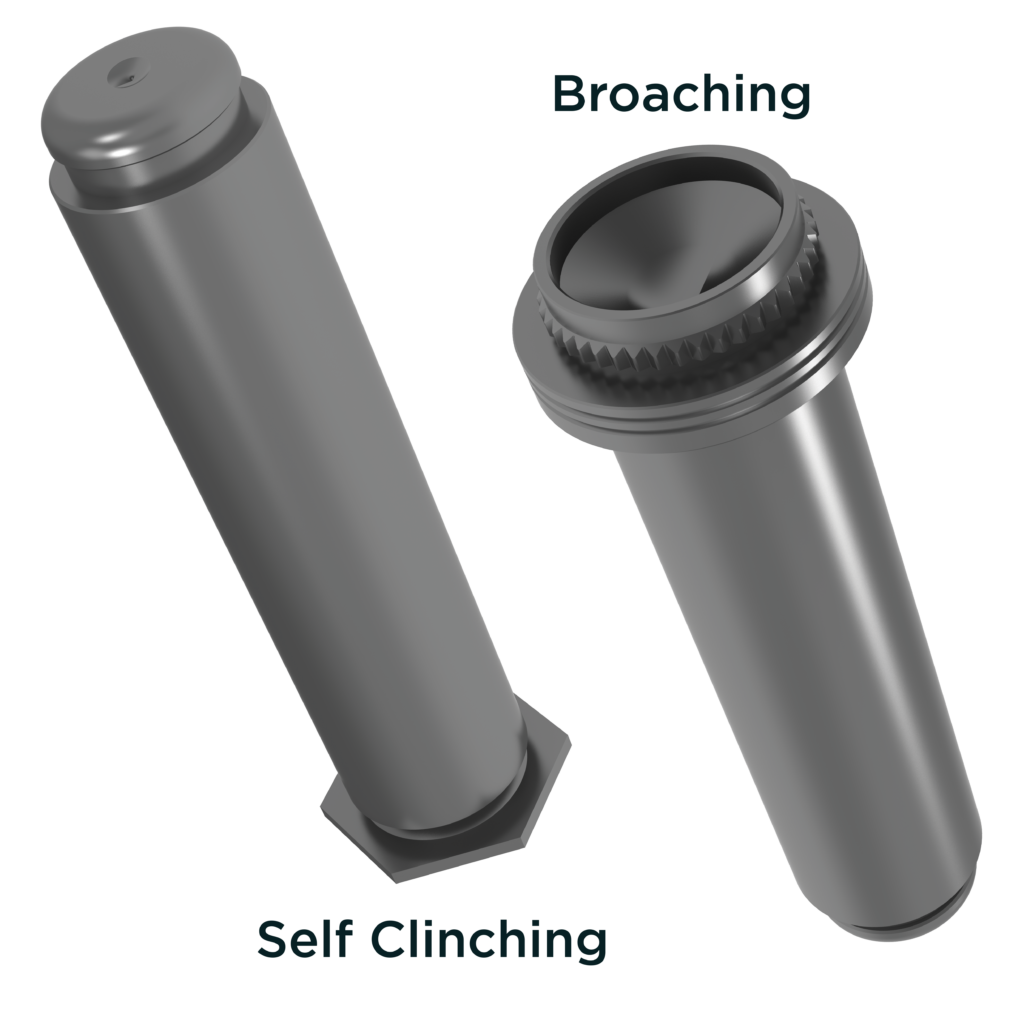

Clinch nuts are identified by their self-clinching attachment features and recognized for their versatility in sheet metal applications. However, press fit nuts using broaching features and soldered SMT nuts can be attached to PCBs when the panel material cannot be plastically deformed.

Relevant Products from PEM:

Explore relevant products in our Product Finder:

To learn more about our clinch nut catalog, visit the following datasheets:

CL Datasheet - Standard profile, self-clinching nuts

SS Datasheet - Self-clinching nuts for use in stainless steel sheets

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736