Nuts | Locking Nuts

Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

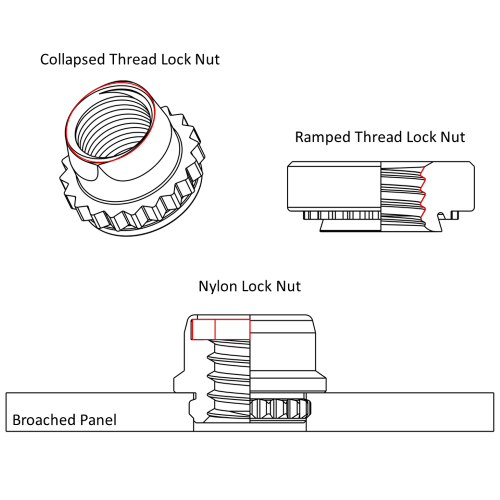

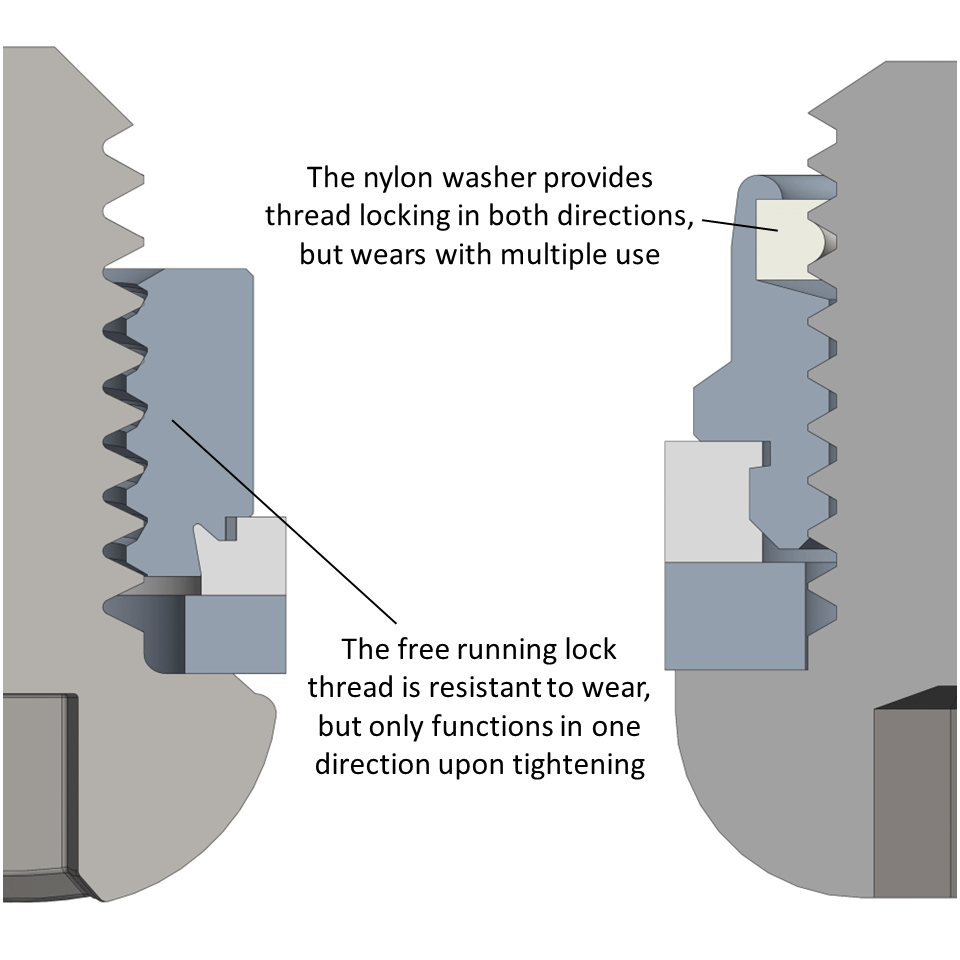

Also known as vibration-proof or self-locking nuts, versatile locking nuts are unique in their ability to increase the torque required to tighten or loosen a mating thread. Adding a nylon component that approaches the minimum diameter of the thread uses the compression of the nylon to induce torque via friction. Collapsing the barrel into a more elliptical shape binds with the mating thread to increase friction as well. Changing the internal thread profile to have a ramped outer diameter (also known as a free-running locknut thread) increases prevailing torque upon preloading by deflecting the male thread.

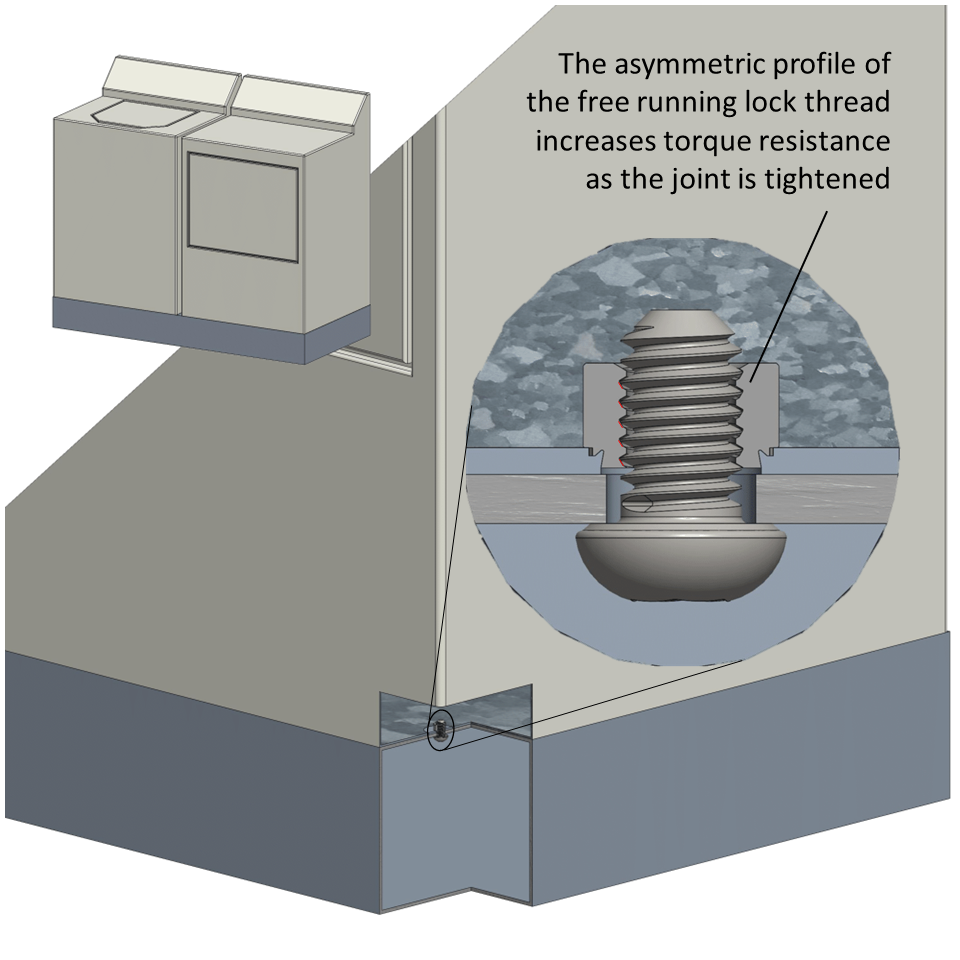

Application

Locking nuts are useful in any application that involves cyclic loading or vibration. Take a washing machine in a commercial context, for example. The machines are mounted on a low platform to allow easy maintenance access. Over time, vibrations induced by the machine’s rotating drum could cause a screw to back out of a regular thread in the platform. But this problem is solved with a free running locknut. The increased prevailing torque upon tightening created by the altered thread profile helps keep the screw secure during use.

The free running lock thread profile helps a joint withstand the regular vibration induced by the washing machine.

A comparison of the utility of two different thread locking solutions; the free running locknut and the nylon washer locknut.

Alternative Solutions

While the free running locknut allows a screw to turn freely until tightened, it’s held back by its directional dependence, since the ramped thread only works as intended when screwing from one side. The prevailing torque for Nylon insert and collapsed thread locking nuts is active for the entire engagement of the thread and can limit the number of uses as they wear out. An alternative to locking threads entirely is the split washer, which compresses like a spring to increase the prevailing torque of a joint. In some cases, however, split washers have proven to be ineffective locking devices while facilitating vibrational loosening – working more as an anti-rotation mechanism in softer materials where the sharp edge can dig into the surface.

Common Attachment Technologies

Most locking nuts are loose parts or self-clinching for metal panels. Broaching or surface mount (SMT) locking nuts for PCBs are rare likely because a circuit board is more likely to be fastened to a metal panel via a self-clinching standoff or nut in vibration-heavy applications. Locking threads can also be retained in a captivated nut, allowing for some float while still increasing prevailing torque.

Relevant Products from PEM:

Explore a wide variety of feature combinations and material selections in our Product Finder:

To learn more, visit the LN Datasheet for nylon and all-metal locking nuts.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736