Specialty Fasteners | Panel-to-Panel

Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

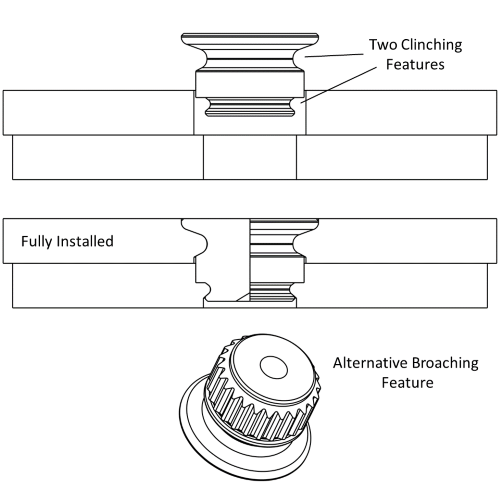

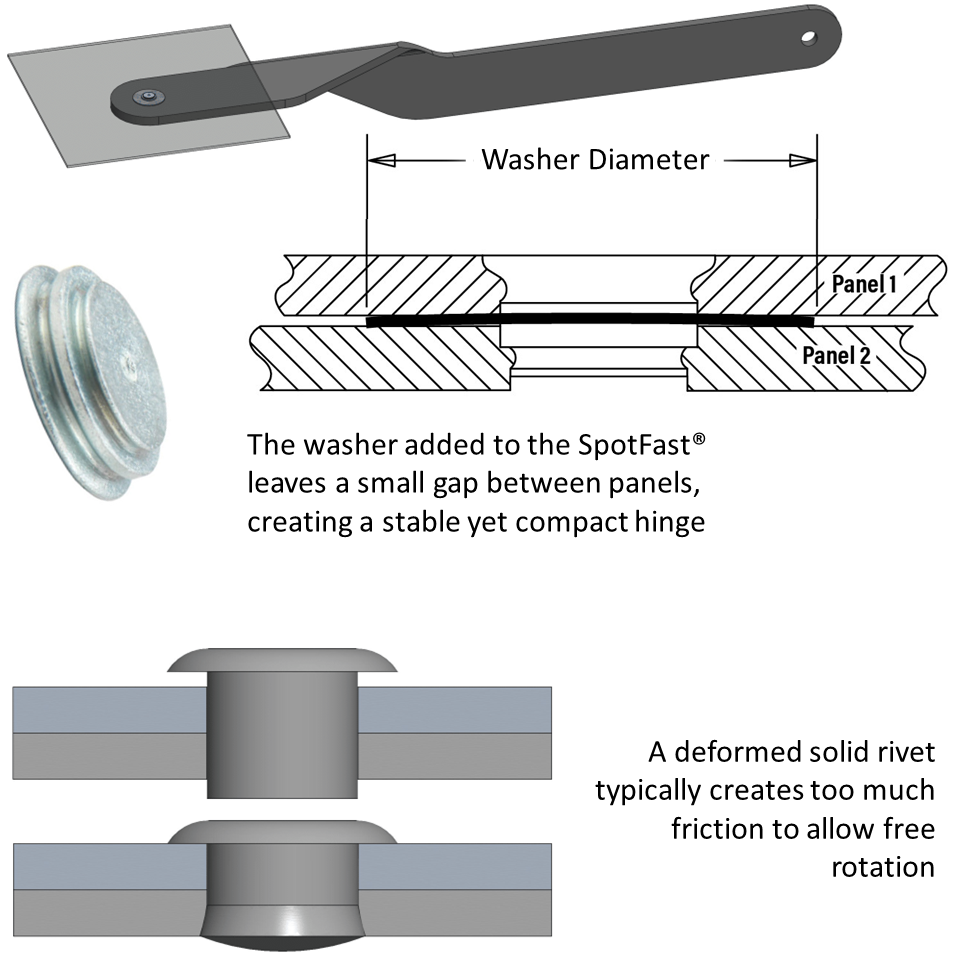

SpotFast® fasteners are meant to emulate the function of spotwelding in which two parallel panels are joined face-to-face without having any protruding geometries on either side. This fastener has two separate self-clinching features that sit on top of each other so two metal panels can be joined while installing only from one side, flowing the panels into their respective undercuts. The middle section of the barrel can be extended for thicker panels or to accommodate a washer that allow for the panels to spin against one another. This washer can also be replaced with a third panel to create some interesting rotating joints.

Application

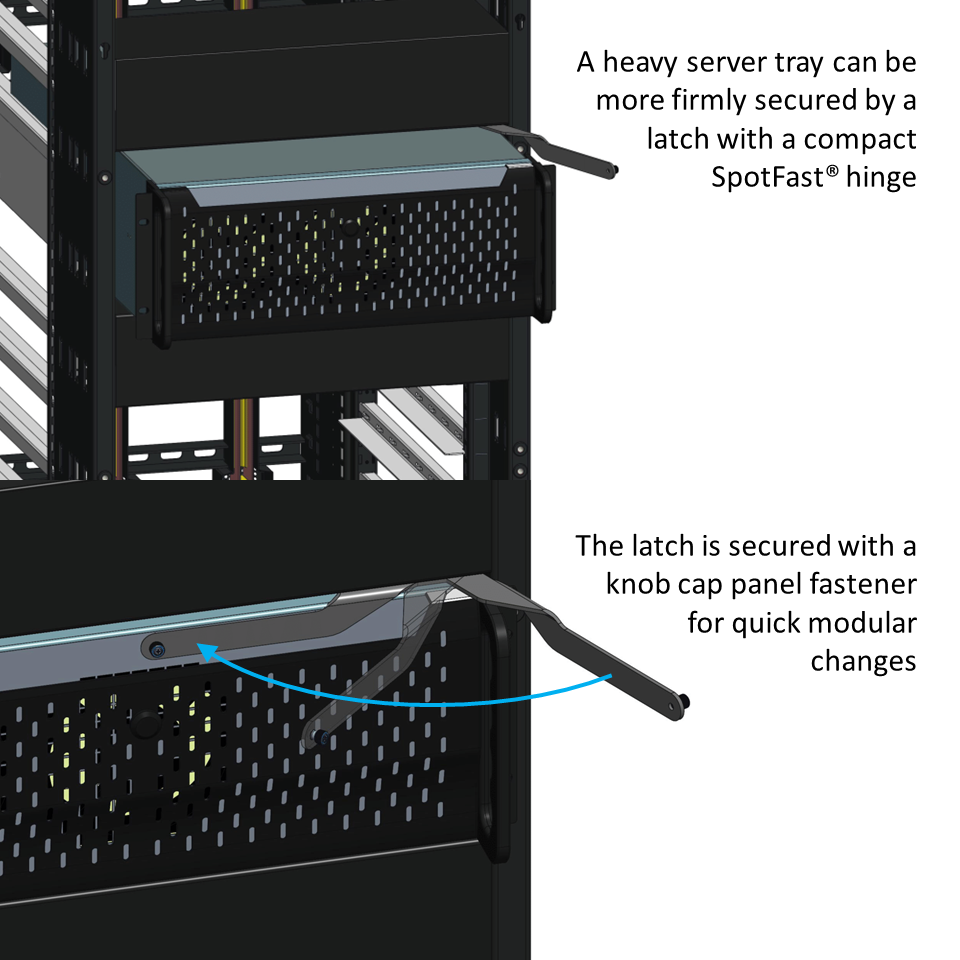

Server racks are a common application in which tight tolerances and maximizing useful space are prioritized. Some server racks have components on a tray that roll out on a rail for easy access and maintenance, which are then locked in place using a swinging arm that latches over the face of the server with a captive screw that can be tightened by hand. While a traditional hinge would require space for the spine whether protruding outward or encroaching on the electrical components, a SpotFast® fastener can keep a low profile by pinning the latching arm to the server tray on top of a washer, allowing the arm to spin freely with very little deflection. This provides a sturdy, compact way to secure an otherwise free-rolling tray in the server rack.

Panel-to-panel fasteners find very unique applications leveraging their clinching design as opposed to solid rivets,

with a washer option allowing for compact hinge assemblies.

Alternative Solutions

While the SpotFast® fastener is a simple, compact solution in its own right, solid rivets can often outcompete them on cost. Solid rivets are essentially short, unthreaded studs that are slightly longer than the thickness of a stack of panels to be joined. The barrel is deformed with a press, wedging a small amount of material against the edges of the hole in the stack, keeping everything together. This solution is extremely cost-effective, but what it can’t replicate is the spinning capabilities of the SpotFast® fastener. Higher-end hinge applications often have the requirements to justify a more expensive part.

Common Attachment Technologies

While the double undercut is the main unique feature of the SpotFast® fastener, the pilot undercut can be replaced with straight knurl geometry for broaching into a PCB, allowing for compact connection of panels of dissimilar material. This kind of joint is not as easy to replace with spot welding or solid rivets and makes for a unique solution to a specific problem. The ability to retain a washer or a third panel between two clinched panels also opens the door to unique, compact hinge solutions.

Relevant products from PEM:

Explore options for direct panel-to-panel fasteners in our Product Finder:

To learn more about PEM SpotFast® products and performance data, visit the SF Datasheet.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736