Studs | Locating Pins

Table of Contents

Product Pages

Standoffs

KEYHOLE® Standoffs

SNAP-TOP® Standoffs

Nuts

Clinch Nuts

Floating Nuts

Blind Nuts

Flush Nuts

Locking Nuts

Rivet Nuts

Studs

Locating Pins

Captivated Screws

Simple Screws

Spring-Loaded Screws

Knob Cap Screws

Threaded Inserts

Press-In Inserts

Molded-In Inserts

Ultrasonic/Heat-Staking Inserts

Compression Limiters

Specialty Fasteners

Cable Tie Mounts

TACKPIN®

Panel-to-Panel Fasteners

Right Angle Fasteners

Attachment Technologies

Overview

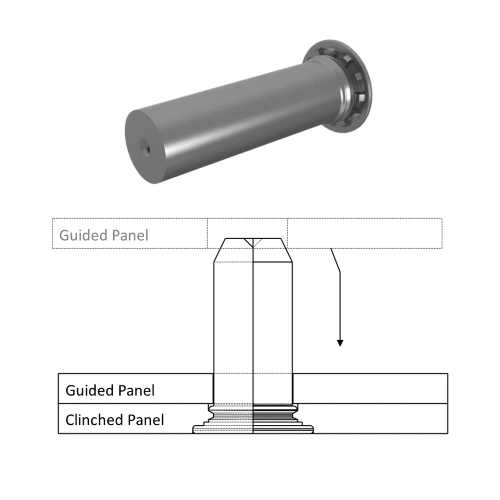

Locating pins or pilot pins are similar in form to studs except for their absence of threads. Instead, they have a round or sometimes diamond profile length with a tapered tip. Since there are no threads to hold a load and the part is only subject to shear loading, there is no need for anti-rotation features, making round bar stock the main raw material geometry for locating pins. They can sit pressure-fit in to a milled hole, as well as more permanent attachment methods for thin panels.

Application

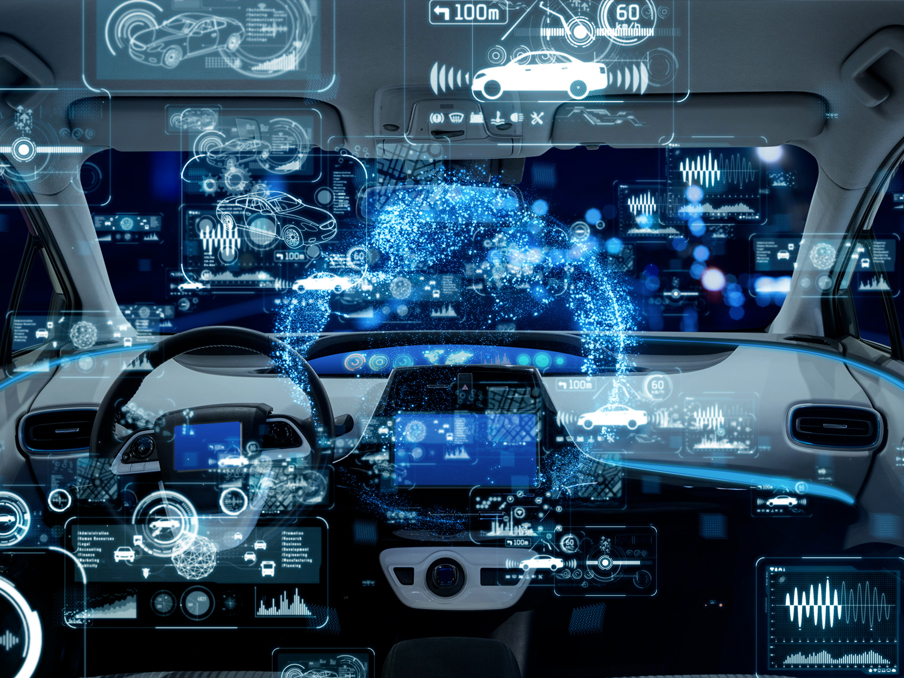

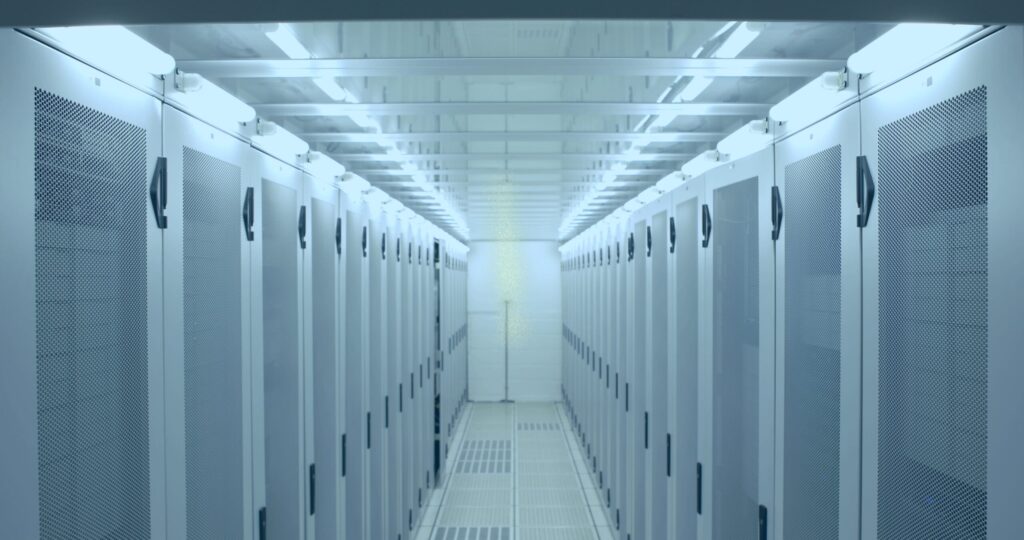

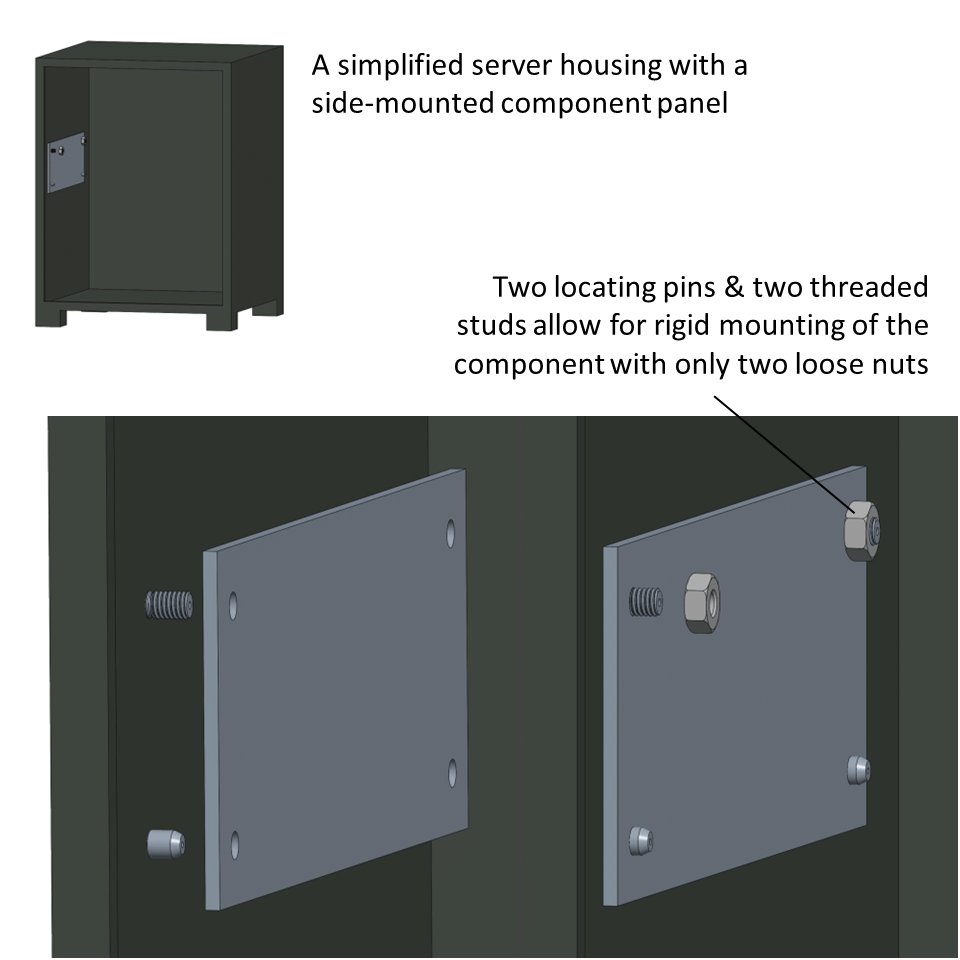

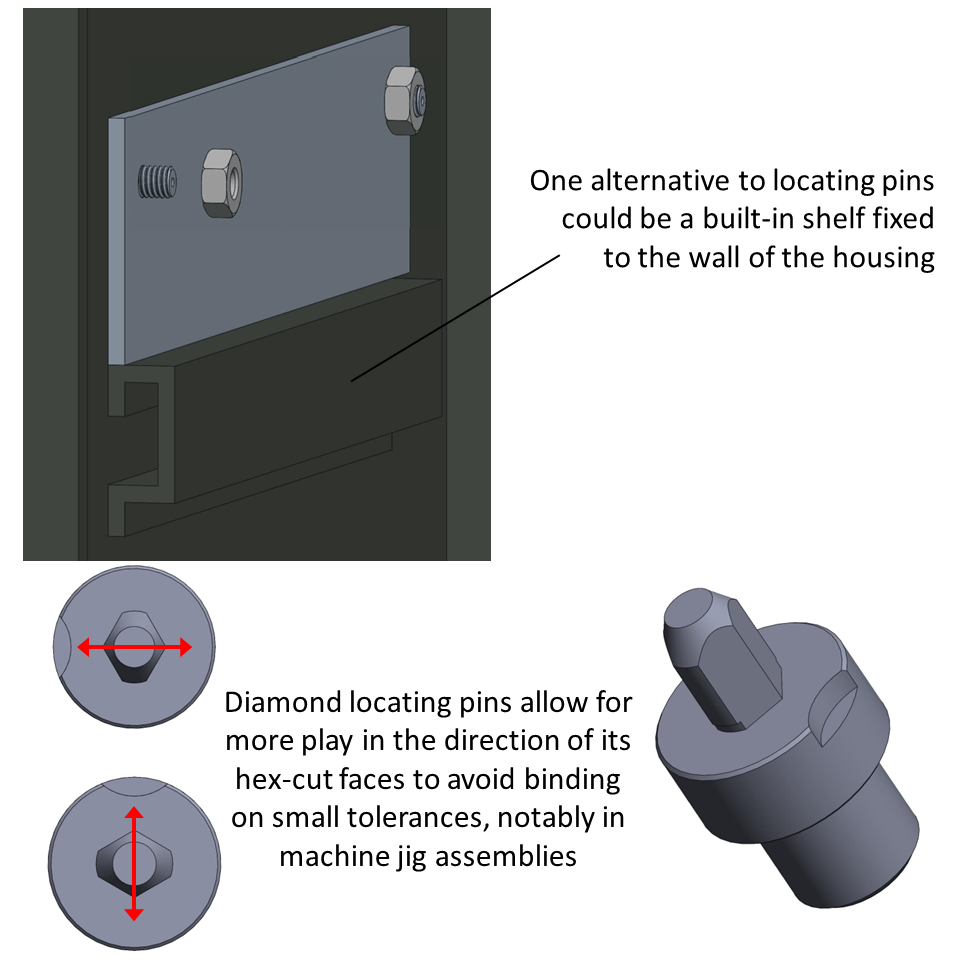

Locating pins help align components prior to fastening, which is especially useful when dimensional accuracy is a priority. Servers for telecom and datacom applications pack many components into the smallest space possible, requiring tight tolerances that become tedious when multiplied into large systems of servers. When fastening to a vertical surface, hardware can be minimized if two of the four attachment points are locating pins instead of studs. This ensures four stable corners with only two loose nuts. Additionally, diamond locating pins can be useful in tandem with round pins for very small tolerance situations, as they allow for some play between pins and reduce the possibility of binding.

Locating pins can be used alongside threaded studs to minimize loose hardware without sacrificing support.

Most alternative solutions to locating pins face tradeoffs between directional stability, manufacturing, and tolerance challenges.

Alternative Solutions

The obvious alternative is to have threaded studs on all four corners, which would ensure restriction of movement in all three axes but require more loose parts and increased install time. A ledge could be designed into the vertical surface to provide the same support with less hardware, but at the expense of flexibility and manufacturing time. However, since locating pins have no axial restriction of movement, they may not be secure enough to replace threads in more mobile applications.

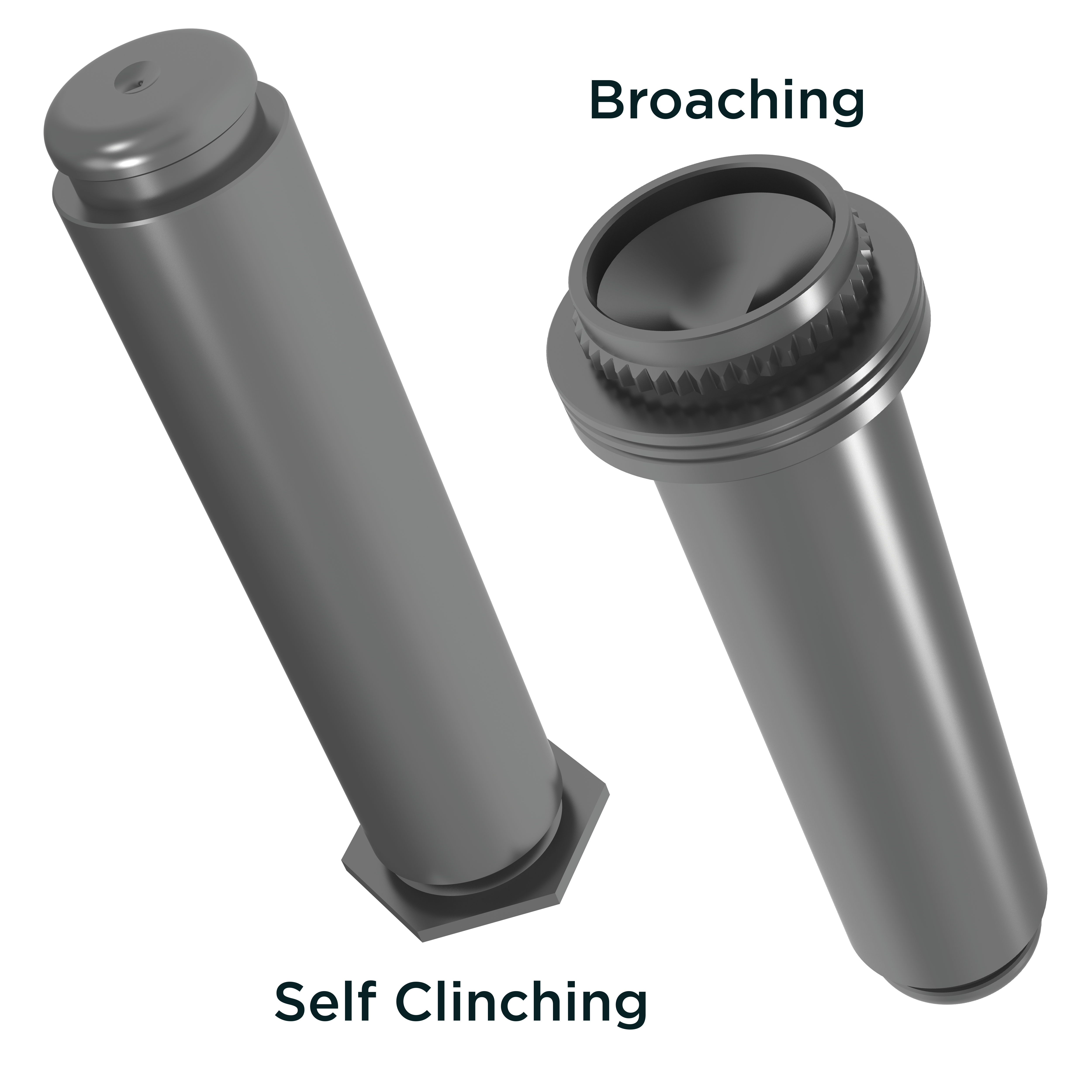

Common Attachment Technologies

In a manufacturing context, locating pins are commonly used for aligning work pieces for some other operation, and may need to be swapped out depending on the work. This favors pressure-fit or screw-clamped fixtures that can be easily mounted and dismounted. For permanent applications, locating pins see more use in metal panels through self-clinching means, making "captive pins" another common name for this fastener. New applications for EVs have seen self-clinching and broaching locating pins used as electrical connections for busbars in vehicle charging stations.

Relevant Products from PEM:

See sizes and material options in our Product Finder:

To learn more, visit the FH Datasheet and EC Datasheet for self-clinching and broaching pins.

Have a project?

Let’s get started.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Talk to us about creating a custom part, tool or process. We are equipped to help you to take on and solve your biggest engineering challenges.

Looking for CAD Downloads?

Access to the original PEM Catalog and CAD downloads.

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Or Call Us: 1-800-342-5736